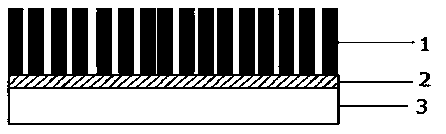

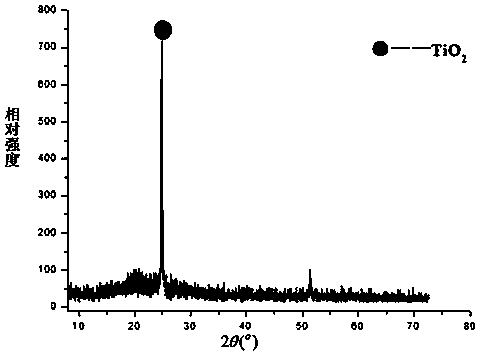

A method for preparing single-crystal anatase tio2 nanorod arrays with superhydrophilic properties

A nanorod array and anatase technology, applied in the field of preparation of TiO2 nanorod array, can solve the problems of uneven diameter, short time, complicated operation process, etc., and achieve the effects of low equipment requirements, large output and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

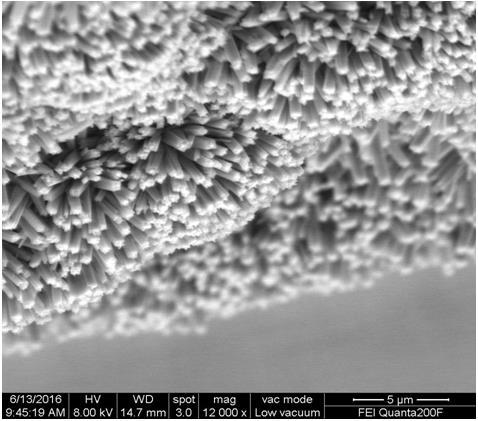

Embodiment 1

[0034] The precursor of the reactant is: TiCl 4 As Ti source, with H 2 O is used as the source of O, and HCl is used as the inhibitor. Measure 40ml of 4mol / L hydrochloric acid solution, add it to the inner lining of the autoclave, stir slowly with a magnetic stirrer, and measure 0.30ml of TiCl with a pipette gun 4 The solution was slowly added dropwise to the polytetrafluoroethylene lining of the autoclave, and after stirring for 20 minutes, the ITO glass sheet was vertically placed in the lining, and the autoclave was placed in an oven, heated to 160°C, and kept for 5 hours , take the reactor out of the oven, cool to room temperature, take the ITO glass sample out of the PTFE lining, rinse the sample with deionized water, and dry it at 80°C, place the sample in a muffle furnace, air Under ambient conditions, heat to 350°C, keep warm for 1h, and cool to room temperature. See the attached table for the results.

Embodiment 2

[0036] The precursor of the reactant is: TiCl 4 As Ti source, with H 2 O is used as the source of O, and HCl is used as the inhibitor. Measure 40ml of 6mol / L hydrochloric acid solution, add it to the inner lining of the autoclave, stir slowly with a magnetic stirrer, and measure 0.45ml of TiCl with a pipette gun 4 The solution was slowly added dropwise to the polytetrafluoroethylene lining of the autoclave, and after stirring for 20 minutes, the ITO glass sheet was vertically placed in the lining, and the autoclave was placed in an oven, heated to 200°C, and kept for 7 hours , take the reactor out of the oven, cool to room temperature, take the ITO glass sample out of the PTFE liner, rinse the sample with deionized water, and dry it at 90°C, place the sample in a muffle furnace, air Under ambient conditions, heat to 450°C, keep warm for 2h, and cool to room temperature. See the attached table for the results.

Embodiment 3

[0038] The precursor of the reactant is: TiCl 4 As Ti source, with H 2 O is used as O source, HCl is used as inhibitor, measure 40ml of 8mol / L hydrochloric acid solution, add it to the lining of the autoclave, stir slowly with a magnetic stirrer, and measure 0.50ml of TiCl with a pipette gun 4 The solution was slowly added dropwise to the polytetrafluoroethylene lining of the autoclave, and after stirring for 20 minutes, the ITO glass sheet was vertically placed in the lining, and the autoclave was placed in an oven, heated to 180°C, and kept for 11 hours , take the reactor out of the oven, cool to room temperature, take the ITO glass sample out of the PTFE liner, rinse the sample with deionized water, and dry it at 100°C, place the sample in a muffle furnace, air Under ambient conditions, heat to 450°C, keep warm for 3h, and cool to room temperature. See the attached table for the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com