A method for simultaneously preparing cellulose fiber and hemicellulose solution

A cellulose fiber and hemicellulose technology, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of expensive membrane modules and low concentration, and achieve the effect of improving economic feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

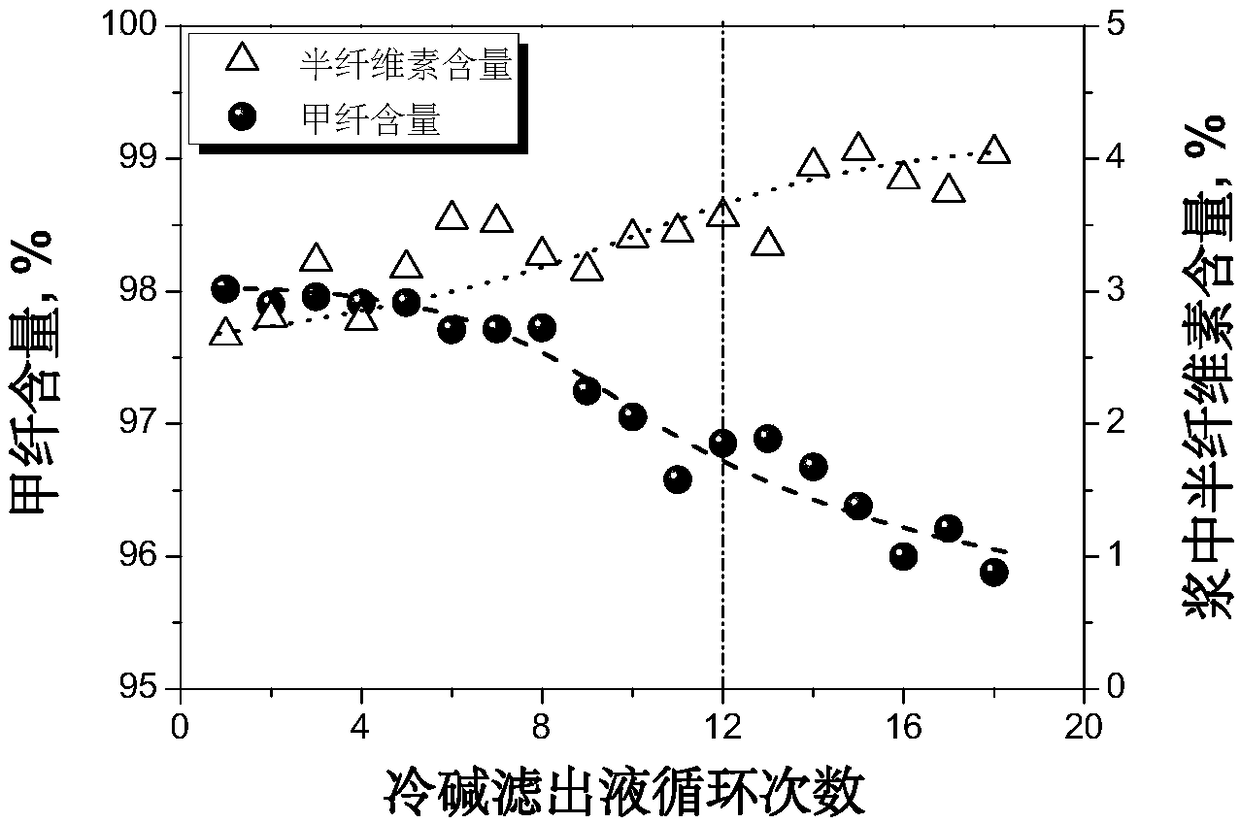

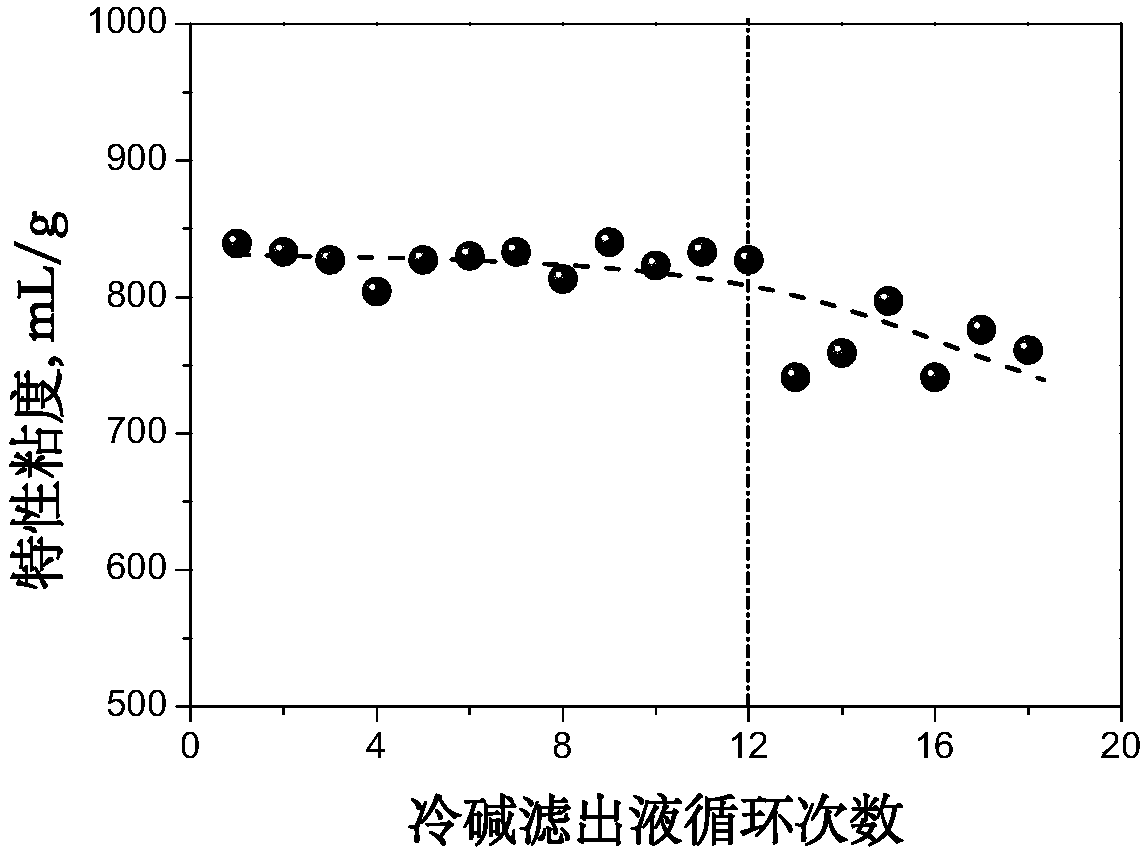

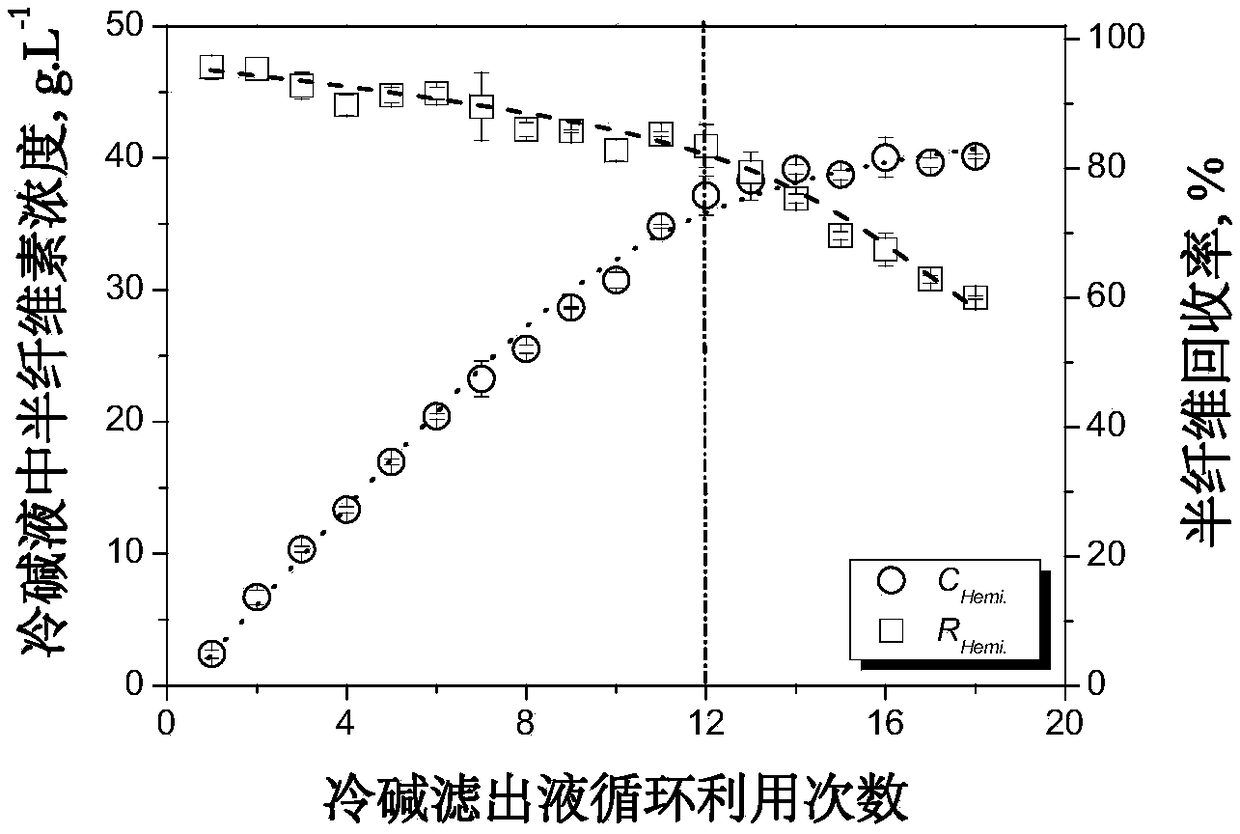

[0026] Repeatedly recycling cold alkali filtrate to purify and bleach sulfate bamboo pulp and obtain high-concentration hemicellulose solution

[0027] (1), (high brightness) chemical pulp cold alkali impregnation: use cold alkali solution with a mass fraction of 8% and a temperature of 25 ° C to impregnate the high brightness chemical pulp for 60min, and the pulp concentration is 5% to obtain (high purity) fiber cellulose and cold lye containing hemicellulose;

[0028] (2), high-efficiency separation of cellulose fibers: after the cold alkali impregnation is completed, the high-purity cellulose fibers and cold lye obtained after the treatment in step (1) are efficiently separated by a double-stick pulper; the double-stick pulper is used for pulping. The concentration is controlled to be 40%, and the obtained cold alkali filtrate and a small amount of soda ash are used to impregnate the next batch of chemical pulp with cold alkali;

[0029] (3) Recycling of cold alkali filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com