Method for purifying aqueous solution of deacetoxycephalosporin C

An aqueous solution and purity technology, applied in the field of biochemistry, can solve problems such as increased production cost, low DAOC purity, affecting conversion yield and finished product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

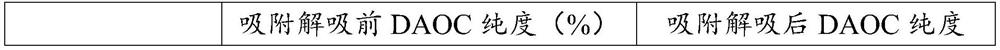

Embodiment 1

[0028] A method for purifying DAOC aqueous solution with adsorption resin, specifically comprises the following steps:

[0029] (1) The DAOC aqueous solution with a potency of 8000 μg / mL was adjusted to pH 2.8 with sulfuric acid, and the temperature was controlled at 15°C;

[0030] (2) according to the adsorption capacity of 35g / L, carry out adsorption treatment through DM700 macroporous adsorption resin at the flow rate of 0.4BV / h to obtain the macroporous adsorption resin containing DAOC;

[0031] (3) washing with 4BV deionized water through the macroporous adsorption resin containing DAOC in step (1) at a flow rate of 0.5BV / h;

[0032] (4) desorb 0.5% sodium bicarbonate solution with 3.5BV concentration through step (3) macroporous adsorption resin containing DAOC at a flow rate of 0.5BV / h, and collect the desorbed liquid;

[0033] After testing, the purity of the desorbed liquid DAOC in the above embodiment was 96.97%, and the desorption rate was 92.11%.

Embodiment 2

[0035] A method for purifying DAOC aqueous solution with adsorption resin, specifically comprises the following steps:

[0036] (1) The DAOC aqueous solution with a potency of 9000 μg / mL was adjusted to pH 2.7 with sulfuric acid, and the temperature was controlled at 17°C;

[0037] (2) according to the adsorption capacity of 36g / L, carry out adsorption treatment through DM700 macroporous adsorption resin at the flow rate of 0.5BV / h to obtain the macroporous adsorption resin containing DAOC;

[0038] (3) washing with 4.5BV deionized water at a flow rate of 0.6BV / h through the macroporous adsorption resin containing DAOC in step (1);

[0039] (4) desorb the 0.4% sodium bicarbonate solution with 3.8BV concentration through step (3) the macroporous adsorption resin containing DAOC at a flow rate of 0.6BV / h, and collect the desorbed liquid;

[0040] After testing, the purity of the desorbed liquid DAOC in the above embodiment was 97.19%, and the desorption rate was 91.82%.

Embodiment 3

[0042] A method for purifying DAOC aqueous solution with adsorption resin, specifically comprises the following steps:

[0043] (1) The DAOC aqueous solution with a potency of 10,000 μg / mL was adjusted to pH 2.9 with sulfuric acid, and the temperature was controlled at 20°C;

[0044] (2) according to the adsorption capacity of 37g / L, carry out adsorption treatment through DM700 macroporous adsorption resin at the flow rate of 0.55BV / h to obtain the macroporous adsorption resin containing DAOC;

[0045] (3) washing with 4.5BV deionized water at a flow rate of 0.5BV / h through the macroporous adsorption resin containing DAOC in step (1);

[0046] (4) desorb 3.0BV concentration of 0.45% sodium bicarbonate solution through step (3) macroporous adsorption resin containing DAOC at a flow rate of 0.4BV / h, and collect the desorbed liquid;

[0047] After testing, in the above embodiment, the purity of the desorbed liquid DAOC is 97.13%, and the desorption rate is 91.87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com