Photocatalytic membrane distillation printing and dyeing wastewater treatment and reuse system and process

A technology of printing and dyeing wastewater and photocatalytic membrane, which is applied in energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve light intensity, reduce investment and operating costs, and improve oxidation rate and effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

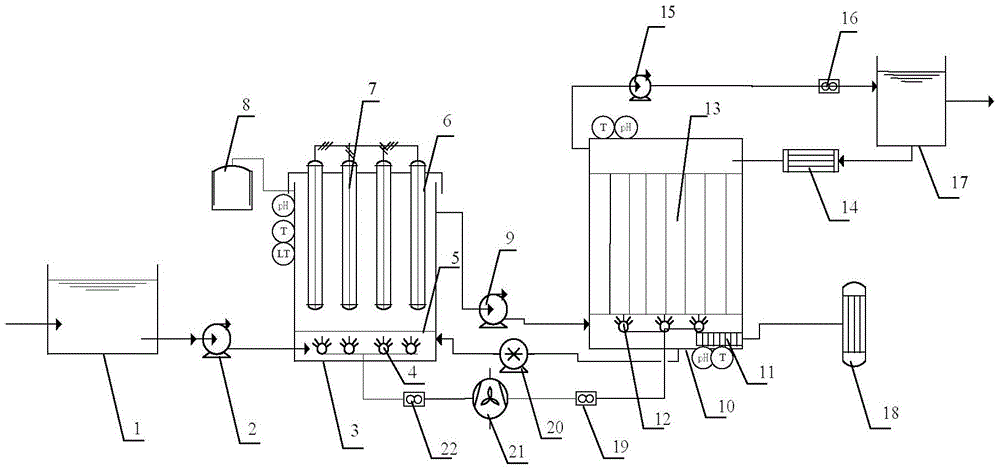

[0030] Such as figure 1 As shown, a photocatalytic membrane distillation printing and dyeing wastewater treatment and reuse system includes an ozone decomposition device 8, a solar energy absorption device 18, and a water inlet pool 1 connected in sequence, a photocatalytic degradation reaction pool 3, a membrane distillation biological reaction pool 10, and a clear water pool 17. The bottom of the water inlet tank 1 and the photocatalytic degradation reaction tank 3 is connected by the first sewage pump 2, and the upper part of the photocatalytic degradation reaction tank 3 and the bottom connecting pipe of the membrane distillation biological reaction tank 10 are provided with a second sewage pump 9, a light The bottom of the catalytic degradation reaction tank 3 and the bottom connecting pipe of the membrane distillation bioreactor 10 are provided with a second circulation pump 20, and the photocatalytic degradation reaction tank 3 and the membrane distillation bioreactor 10...

Embodiment 2

[0039] The above devices and processes are used to treat the production wastewater of a printing and dyeing enterprise in Jiangsu.

[0040] The concentration of COD (chemical oxygen demand) in the photocatalytic degradation reaction pool is 820mg / L, BOD 5 (The amount of free oxygen consumed by aerobic microorganisms to oxidize and decompose organic matter per unit volume of water on the 5th day) The concentration is 270mg / L, the average color of the influent is 370 times, the influent temperature is 16-18°C, and the pH is 7.0-8.0 , the conductivity is 2580μs / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com