Production method of rice weeding paper

A production method and a technology for straw paper, applied in the field of papermaking, can solve the problem that it is difficult to take into account the weeding performance and cost requirements of rice, and achieve the effects of reducing photosynthesis, high opacity, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

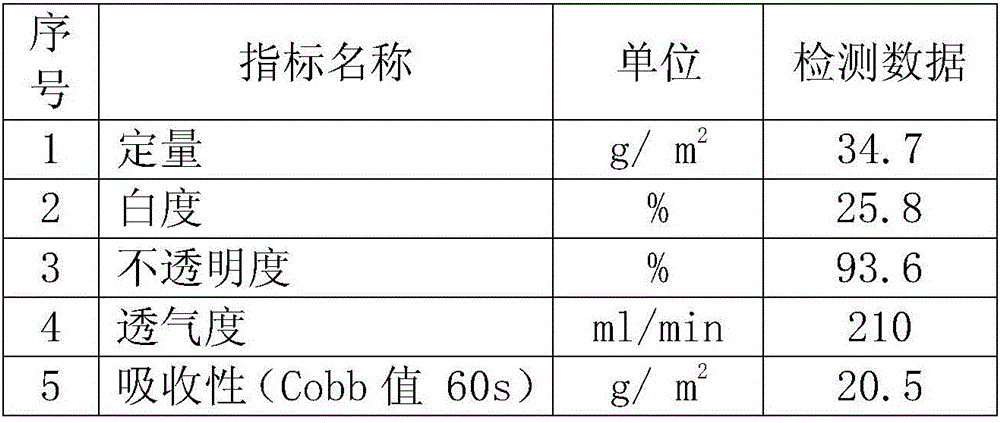

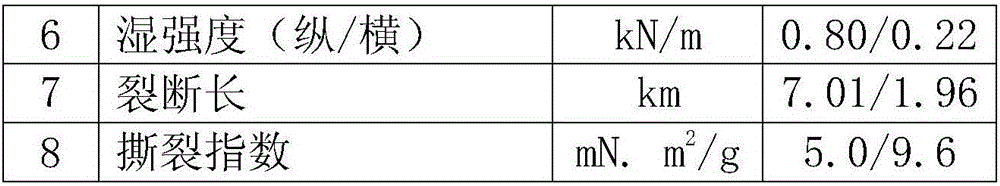

Embodiment 1

[0011] Example 1: 35g / m 2 Rice weeding paper, making speed 130m / min

[0012] Rice weeding paper is produced by ordinary rotary paper machine, with unbleached kraft softwood pulp and unbleached kraft hardwood pulp as main raw materials, carbon black, rosin gum, aluminum sulfate, wet strength agent polyamide polyamine ring Oxychlorohydrin and retention agent polyacrylamide are auxiliary raw materials, and the wet strength agent is added in two steps. The specific process is as follows:

[0013] (1) Ratio of main raw materials and beating: 25% unbleached kraft softwood pulp and 75% unbleached kraft broadleaf pulp; the beating concentration of mixed pulp is 4.2%, and the beating freeness is 210ml.

[0014] (2) Auxiliary raw materials:

[0015] The amount of carbon black is 0.8% / dry pulp; the amount of rosin gum is 0.8% / dry pulp, the amount of aluminum sulfate is 0.9% / dry pulp; the amount of retaining agent is 140ppm / dry pulp.

[0016] The dosage of wet strength agent is 0.8% / d...

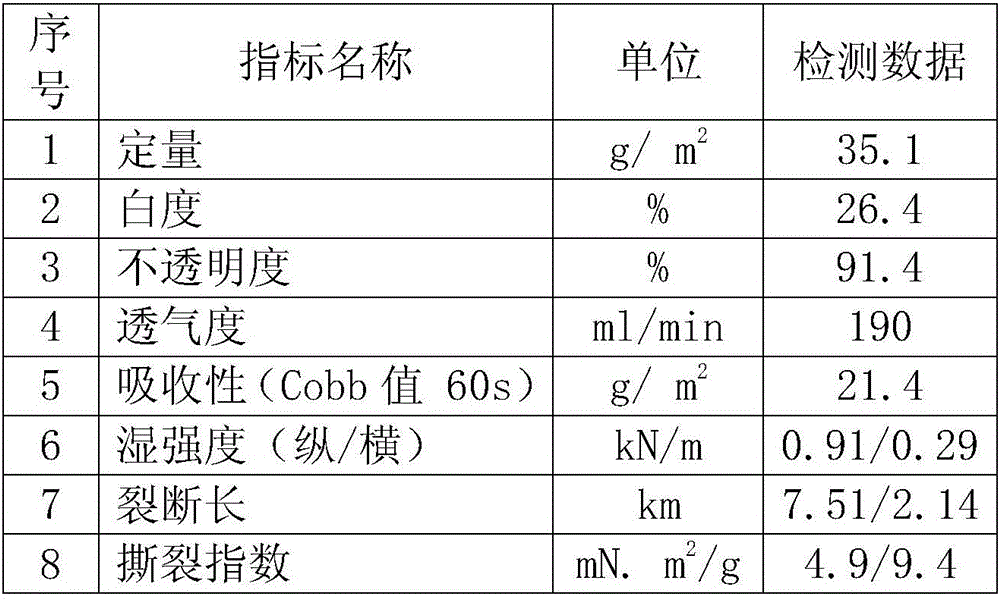

Embodiment 2

[0022] Example 2: 35g / m 2 Rice weeding paper, making speed 140m / min

[0023] Rice weeding paper is produced by ordinary rotary paper machine, with unbleached kraft softwood pulp and unbleached kraft hardwood pulp as main raw materials, carbon black, rosin gum, aluminum sulfate, wet strength agent polyamide polyamine ring Oxychlorohydrin and retention agent polyacrylamide are auxiliary raw materials, and the wet strength agent is added in two steps. The specific process is as follows:

[0024] (1) Ratio of main raw materials and beating: 30% unbleached kraft softwood pulp, 70% unbleached kraft broadleaf wood pulp; the beating concentration of mixed pulp is 4.4%, and the beating freeness is 230ml.

[0025] (2) Auxiliary raw materials:

[0026] The amount of carbon black is 0.7% / dry pulp; the amount of rosin gum is 0.9% / dry pulp, the amount of aluminum sulfate is 0.8% / dry pulp; the amount of retaining agent is 160ppm / dry pulp.

[0027] The dosage of wet strength agent is 0.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com