Ammonia turbine device used for ocean temperature difference power generation

A turbine device and thermoelectric power generation technology, applied in the field of turbines, can solve the problems of unsuitable ammonia working fluid bearing lubrication, heat dissipation, poor sealing performance of micro turbines, leakage, etc., to achieve high hardness, leakage prevention, high durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

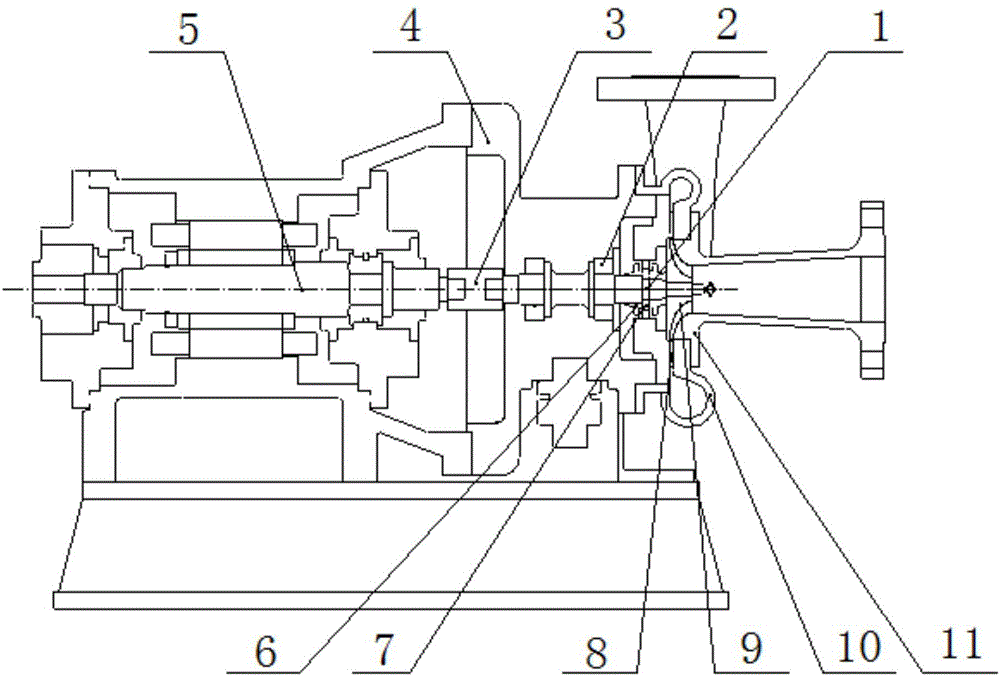

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] As shown in the figure, an ammonia turbine device for ocean temperature difference power generation includes a turbine body, a flow channel system, a shafting system, a power generation system, a sealing system and an oil circuit system, wherein,

[0031] The turbine body 4 is located in the middle of the whole ammonia turbine device, and is the supporting and wrapping part of the whole ammonia turbine device;

[0032] The flow channel system is located on the right side of the turbine body, including the volute 10, nozzle 8, impeller 9 and diffuser 11, the volute cover is on the nozzle and the impeller, the nozzle is set outside the impeller wheel circumference, and the diffuser is located on the impeller The outlet is connected to the volute with screws;

[0033] The shafting system includes the turbine main shaft 1, the bearing 2 and the coupling 3, which mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com