Compressed air energy-storage device based on constant-temperature control

A technology of compressed air energy storage and constant temperature control, applied in pump devices, liquid variable capacity machinery, engine components, etc., can solve the problems of low energy storage utilization efficiency and incomplete utilization of compressed air potential energy, and achieve energy storage utilization. High, simple structure, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

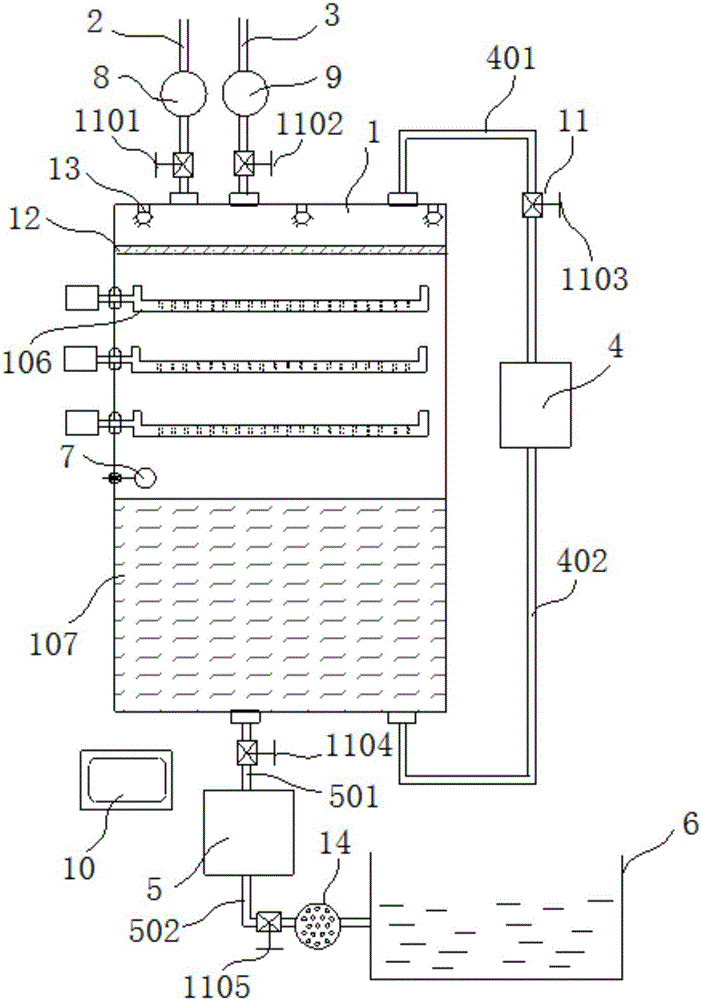

[0037] like figure 1 As shown, the compressed air energy storage device based on constant temperature control of the present invention includes:

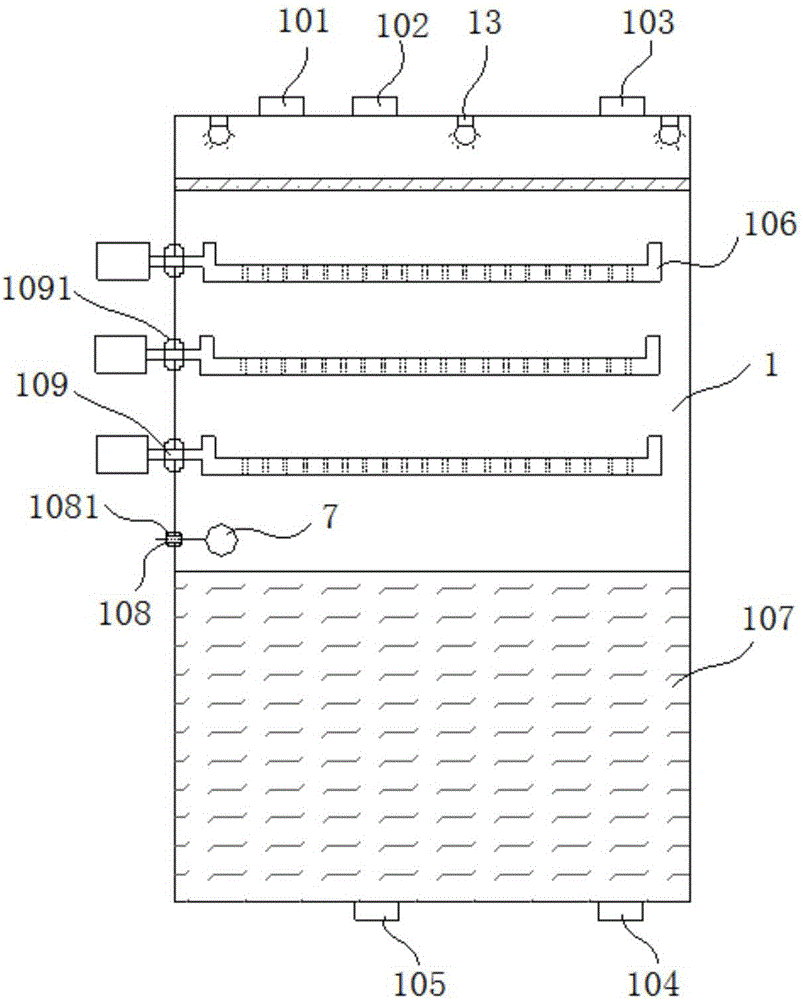

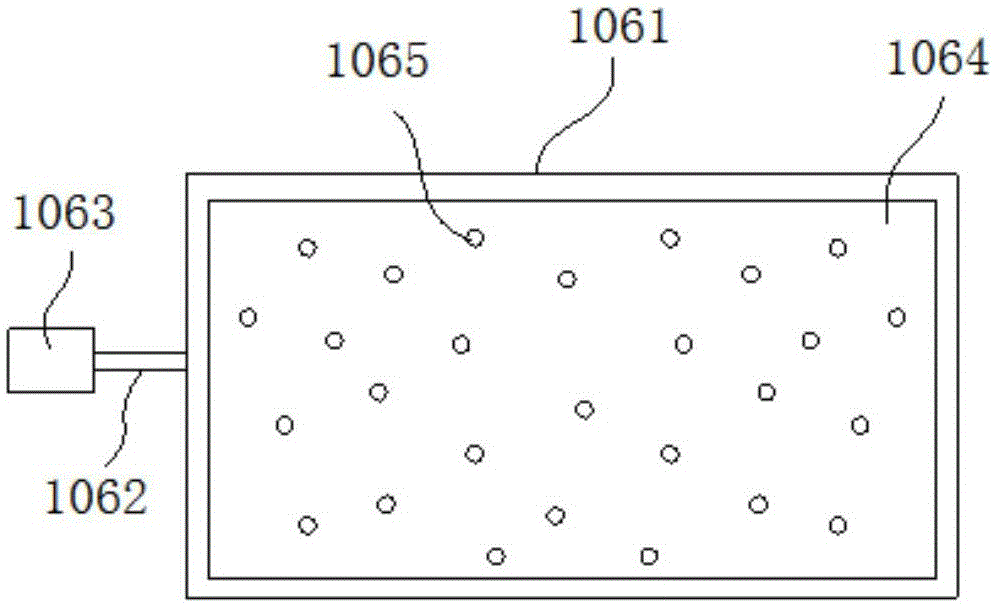

[0038] Liquid piston 1, such as figure 2 As shown, the upper part of the liquid piston 1 is provided with a first port 101, the second port 102, and the third port 103, and the lower part of the liquid piston 1 is provided with a fourth port 104 and a fifth port 105. A plurality of rotatable liquid storage plates 106 are arranged above the inside of the piston 1 , and multi-layer packing 107 is arranged under the inside of the liquid piston 1 . In this example, if image 3 As shown, the rotatable liquid storage plate 106 includes a rotating plate 1061, a rotating shaft 1062, and a rotating motor 1063. The first end of the rotating shaft 1062 is connected to the rotating plate 1061, and the second end of the rotating shaft 1062 The end passes through the side wall of the liquid piston 1 and is connected to the rotary motor 1063 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com