Check ash valve used for sound wave ash blower

A sound wave sootblower and check technology, which is applied to lift valves, valve details, control valves, etc., can solve problems such as the stuck sounding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

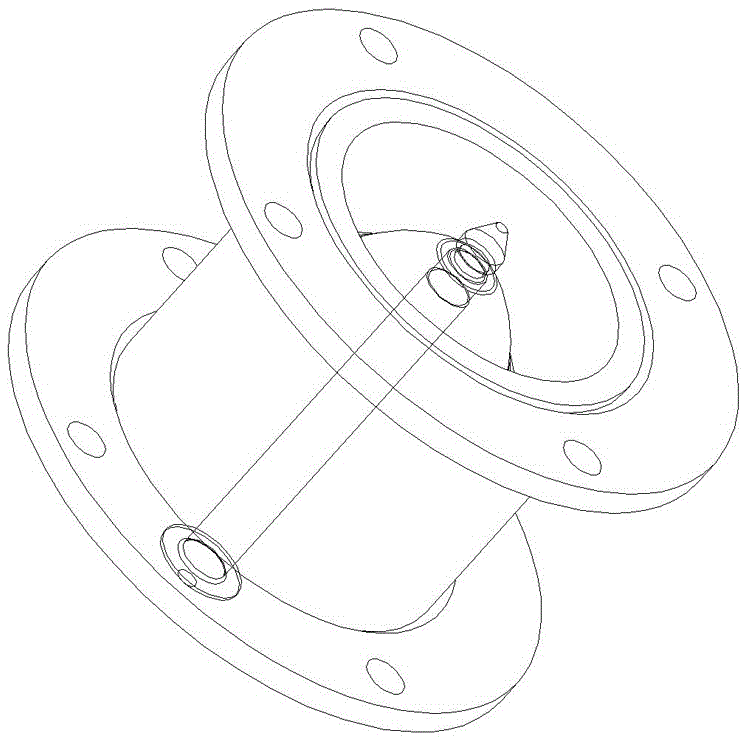

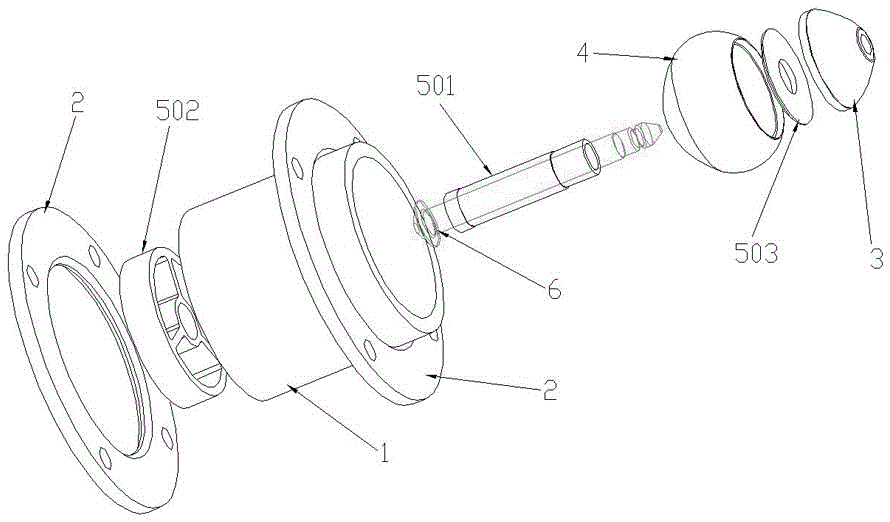

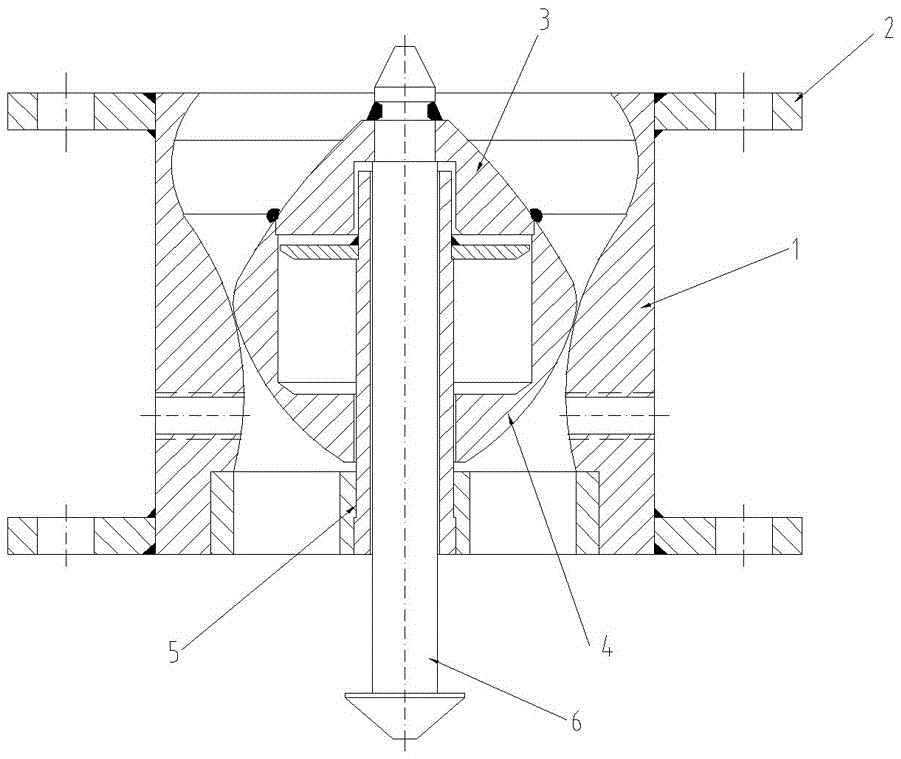

[0033] combined with figure 1 to attach Figure 14, a check valve for sonic sootblowers, which includes a valve body 1 and a sliding rod 6, a flange 2 is installed at the upper and lower ends of the valve body 1, and an upper valve core is installed inside the valve body 1 3. The lower valve core 4 and the valve seat assembly 5, the valve seat assembly 5 is connected with the valve body 1, the valve seat assembly 5 is composed of the lower base 502, the sleeve 501 and the horizontal plate 503, the slide rod 6 is connected from the valve The lower end of the body 1 passes through the sleeve 501 and the upper valve core 3 .

[0034] Preferably, the upper spool 3 and the lower spool 4 are connected together by welding, and after welding, the curved surfaces of the upper spool 3 and the lower spool 4 are smoothly connected to form a gradual and smooth outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com