Air separation system and method utilizing pressure energy of high-pressure natural gas pipeline network

A natural gas pipeline network and air separation technology, applied in the application field of high-pressure natural gas pressure difference refrigeration, can solve the problems of low energy utilization rate and high energy consumption of air separation technology, reduce energy consumption, facilitate safe operation, save investment and The effect of operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

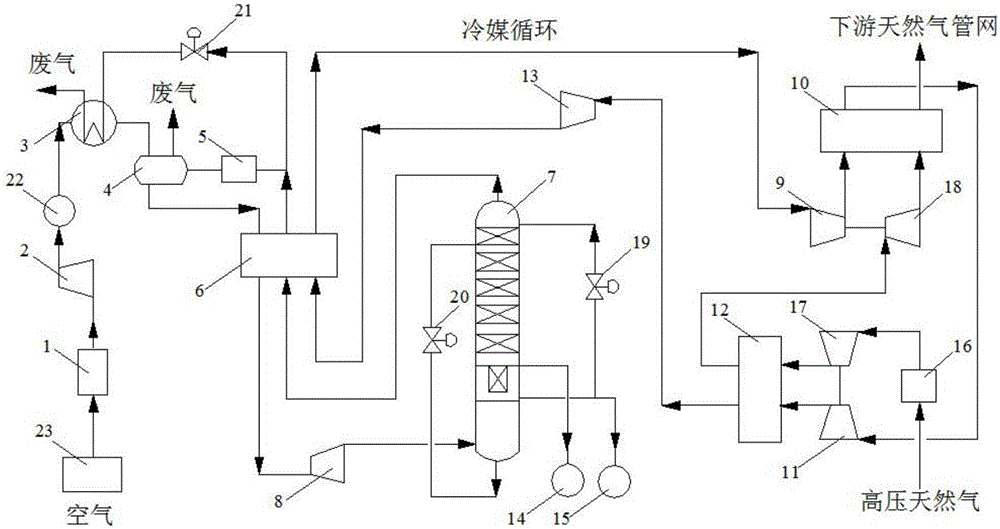

[0044] An air separation system using the pressure energy of the high-pressure natural gas pipeline network, its process flow is as follows figure 1 As shown, the two-stage expansion and decompression method is adopted, and nitrogen is selected as the refrigerant cycle.

[0045] A natural gas distribution station, the total distribution volume is 100×10 4 N m 3 / d, the pressure of the high-pressure natural gas transported from the main natural gas pipeline network to the distribution station is 7.0MPa, the temperature is 20.0°C, the volume composition of the natural gas is shown in Table 1, and the ambient temperature is 25.0°C. The dew point is 15.0°C, and the 7.0MPa high-pressure natural gas in the distribution station needs to be reduced to 2.0MPa before entering the medium-pressure natural gas pipeline network for distribution. The pressure released by the pressure regulation of all incoming gas in the current distribution station can be used for refrigeration, providing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com