Method for microwave digestion of glass body

A microwave digestion and vitreous body technology, applied in the field of analysis and measurement, can solve the problems of incompletely digested vitreous body, etc., achieve the effect of reducing the requirements of digestion equipment, eliminating corrosion, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

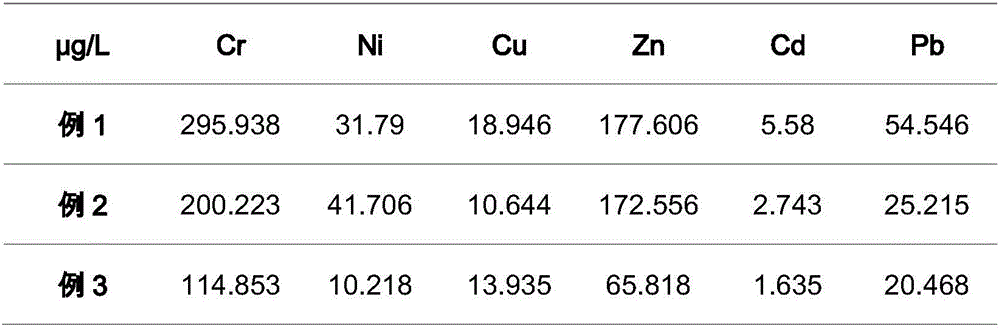

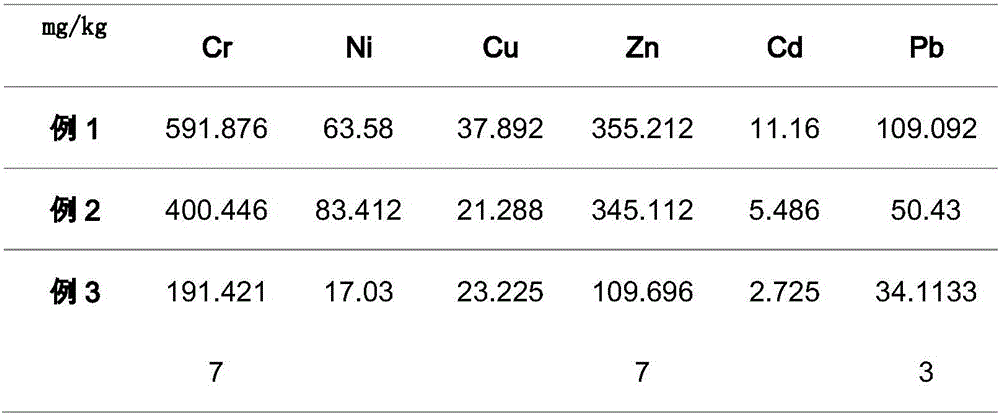

Embodiment 1

[0021] The method of microwave digestion of vitreous includes the following steps:

[0022] (1) Put the glass sample (fly ash slag) in the digestion tank, add 4 drops of ultrapure water to the glass sample, so that the glass sample is immersed in ultrapure water, add nitric acid to obtain a mixed solution, after the mixed solution is stable , Add perchloric acid, hydrofluoric acid and ultrapure water in turn, seal the digestion tank, put the digestion tank into the microwave digestion apparatus, microwave heating for 9 minutes;

[0023] (2) Take out the digestion tank; cool to room temperature, open the digestion tank lid, add ultrapure water to the 21ml mark, seal the digestion tank, place it in the microwave digestion apparatus again, and microwave for 8 minutes;

[0024] (3) Repeat step (2) 3 times;

[0025] (4) Take out the digestion tank; cool to room temperature, open the cover of the digestion tank, and transfer the digestion solution to a volumetric flask to make a constant vo...

Embodiment 2

[0028] The method of microwave digestion of vitreous includes the following steps:

[0029] (1) Put the glass sample (fly ash slag) in the digestion tank, add 3 drops of ultrapure water to the glass sample, so that the glass sample is immersed in ultrapure water, add nitric acid to obtain a mixed solution, after the mixed solution is stable , Add perchloric acid, hydrofluoric acid and ultrapure water in turn, seal the digestion tank, put the digestion tank into the microwave digestion apparatus, microwave heating for 8 minutes;

[0030] (2) Take out the digestion tank; cool to room temperature, open the digestion tank lid, add ultrapure water to the 20ml mark, seal the digestion tank, place it in the microwave digestion apparatus again, and microwave for 8 minutes;

[0031] (3) Repeat step (2) 3 times;

[0032] (4) Take out the digestion tank; cool to room temperature, open the cover of the digestion tank, and transfer the digestion solution to a volumetric flask to make a constant vo...

Embodiment 3

[0035] The method of microwave digestion of vitreous includes the following steps:

[0036] (1) Put the vitreous sample (household waste incineration residue) in the digestion tank, add 5 drops of ultrapure water to the vitreous sample, so that the vitreous sample is immersed in ultrapure water, add nitric acid to obtain a mixed solution, after the mixed solution is stable , Add perchloric acid, hydrofluoric acid and ultrapure water in turn, seal the digestion tank, put the digestion tank into the microwave digestion apparatus, microwave heating for 10 minutes;

[0037] (2) Take out the digestion tank; cool to room temperature, open the digestion tank lid, add ultrapure water to the 22ml mark, seal the digestion tank, place it in the microwave digestion apparatus again, and heat for 7 minutes in the microwave;

[0038] (3) Repeat step (2) twice;

[0039] (4) Take out the digestion tank; cool to room temperature, open the cover of the digestion tank, and transfer the digestion solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com