Vehicle body structure for railway vehicle and forming method

A car body structure and rail vehicle technology, applied in railway car body, railway car body parts, railway roof and other directions, can solve the problems of insignificant lightweight effect of car body structure, lack of experience in mechanical performance design of new materials, etc. The effect of heavy weight is obvious, the effect of eliminating the influence of welding heat-affected zone and residual stress, and reducing the weight of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

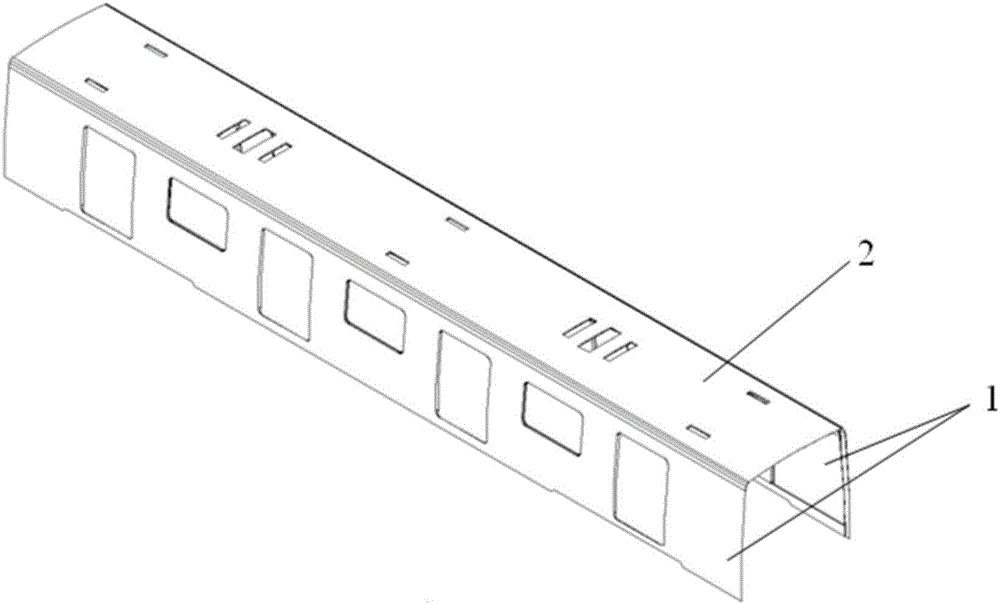

[0018] refer to figure 1 , the car body of the present invention integrates the side wall 1 and the roof 2 in the traditional metal car body structure, and is integrally formed by the OOA process.

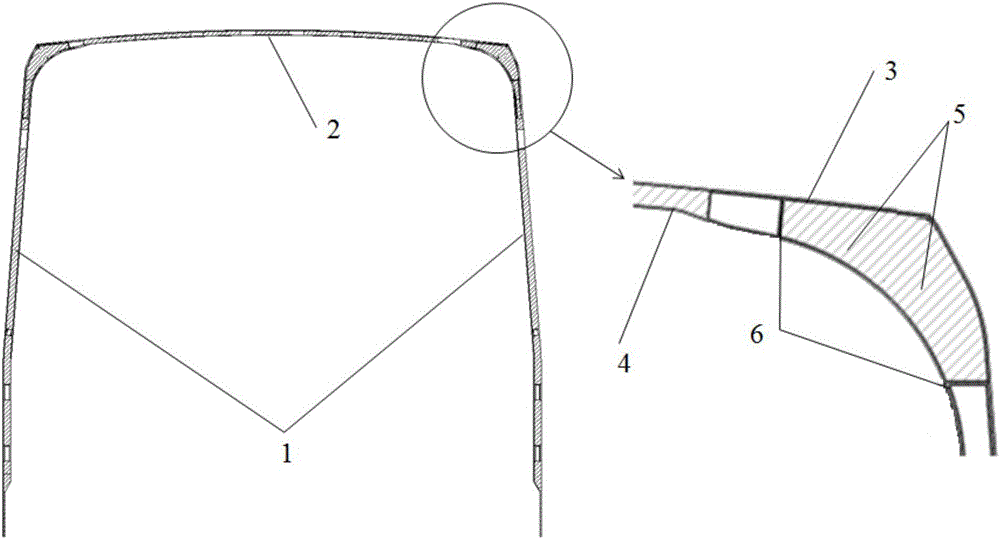

[0019] refer to figure 2 The rail vehicle body of the present invention adopts a sandwich structure in which the inner and outer skins are filled with a paper honeycomb core material, mainly including an outer skin 3, an inner skin 4, a paper honeycomb core material 5, and a reinforced skeleton 6. The section thickness dimension of the vehicle body side wall 1 area is 37mm, wherein the thickness of the inner and outer skins 3 and 4 is 2mm, and the thickness dimension of the paper honeycomb core material is 33mm; the section thickness dimension of the roof 2 area is 27mm, wherein the thickness of the inner and outer skins 3 and 4 are both 2mm, and the thickness of the paper honeycomb core material is 23mm. The inner and outer skins 3 and 4 of the car body are all made of EV101 / HF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com