Elevator capable of realizing continuous sterilization

A disinfection and sterilization technology, which is applied to elevators in buildings, disinfection, paint containing biocide, etc., can solve problems that affect the health of people in elevators, cannot meet high-end elevators, and cannot effectively sterilize elevators. Achieve the effect of improving the sterilization effect, lasting for a long time, and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0140] The preparation method of the second sterilizing coating only includes three steps, the preparation process is simple, the operation is easy, the technological condition requirement is simple, and the implementability is strong.

[0141] Further, the third sterilizing coating is made of the following raw materials in parts by mass:

[0142] Lauryl alcohol polyoxyethylene ether 0.01-0.03 parts

[0143] Glycerin oleate 0.01-0.03 parts

[0144] Nano phosphopeptide 0.01-0.03 parts

[0145] 5-10 parts of epoxy resin

[0146] Nano negative ion powder 0.1-0.4 parts

[0147] Nano titanium dioxide 0.1-5 parts

[0148] Nano medical stone 0.1-5 parts

[0149] Coupling agent 0.1-0.2 parts

[0150] 90-150 parts of water.

[0151] Preferably, the third sterilizing coating is made of the following raw materials in parts by mass:

[0152] Lauryl alcohol polyoxyethylene ether 0.02-0.03 parts

[0153] Glycerin oleate 0.02-0.03 part

[0154] Nano phosphopeptide 0.02-0.03 parts ...

Embodiment 1

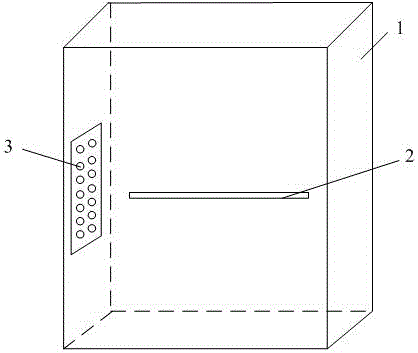

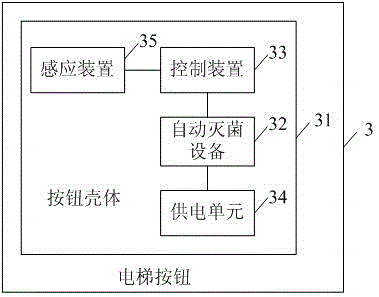

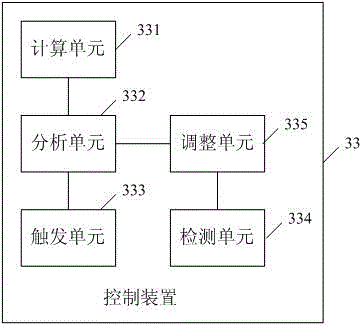

[0167] The elevator of the present invention comprises an elevator body 1, an elevator handrail 2 and an elevator button 3, the surface of the elevator body 1 is coated with a first sterilizing coating, the surface of the elevator handrail 2 is coated with a second sterilizing coating, The elevator button 3 includes a button housing, the surface of the button housing is coated with a third sterilizing coating, and the button housing is provided with an induction device, an automatic sterilization device, a control device and a power supply unit. The automatic sterilization equipment is connected with the control device and the power supply unit, and the control device is connected with the induction device. The automatic sterilization equipment includes an ultraviolet disinfection lamp; the sealed cavity of the ultraviolet disinfection lamp contains indium scandium mercury ternary alloy, indium : Mercury: Scandium = 92:1:2, the inner diameter of the UV disinfection lamp is Ø3mm...

Embodiment 2

[0180] The elevator of the present invention comprises an elevator body 1, an elevator handrail 2 and an elevator button 3, the surface of the elevator body 1 is coated with a first sterilizing coating, the surface of the elevator handrail 2 is coated with a second sterilizing coating, The elevator button includes a button housing, the surface of the button housing is coated with a third sterilizing coating, and an induction device, an automatic sterilization device, a control device and a power supply unit are arranged inside the button housing, and the automatic The sterilization equipment is connected with the control device and the power supply unit, the control device is connected with the induction device, and the automatic sterilization equipment includes an ultraviolet disinfection lamp; the sealed cavity of the ultraviolet disinfection lamp contains indium scandium mercury ternary alloy, indium: Mercury:Scandium=93:1:2, the inner diameter of the UV disinfection lamp is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com