Polyvinylidene fluoride polymer and preparation method thereof

A technology of polyvinylidene fluoride and self-vinylidene fluoride, which is applied in the field of polyvinylidene fluoride polymers and its preparation, can solve the problems of sacrificing PVDF strength and flexural modulus, and achieve increased rigidity, improved flexibility, and high tensile strength Effect of Strength and Flexural Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

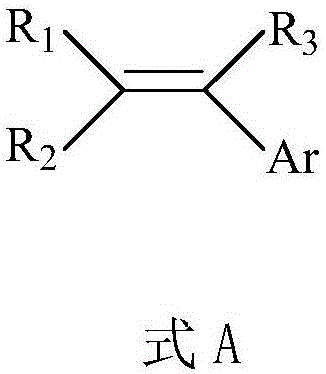

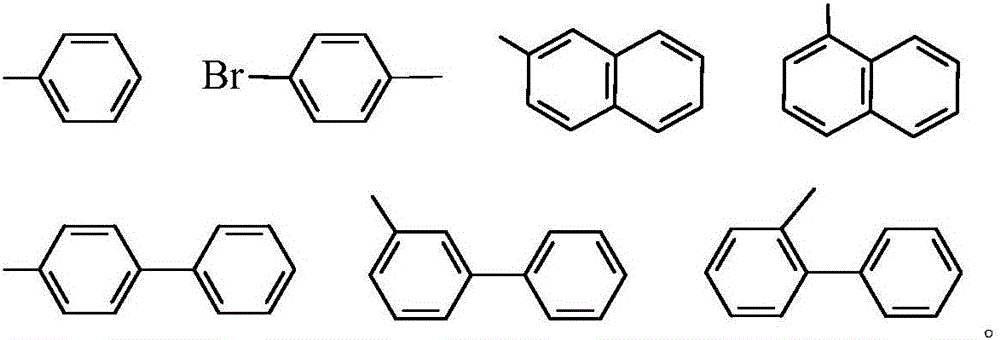

[0032] The preparation method of a kind of polyvinylidene fluoride polymer of the present invention, comprises VDF monomer and the aromatic vinyl monomer of formula A in polymerization medium, in organic initiator, dispersant, chain transfer agent and deionized water In the presence of VDF, free radical suspension polymerization is carried out, and then PVDF resin is obtained through washing and drying steps. In the polymerization step, 100 parts by weight of deionized water, 20-34 parts of VDF monomer, and 0.002 parts of monomer (A) ~6 parts, organic initiators are diethyl peroxydicarbonate, dicyclohexyl peroxydicarbonate, tert-butyl peroxyneodecanoate, diisopropyl peroxydicarbonate, di-n-propyl peroxydicarbonate Esters, tert-butyl peroxypivalate, organic initiator is preferably 0.01 to 0.2 parts, dispersant is methyl cellulose ether, hydroxyethyl cellulose ether, hydroxypropyl methyl cellulose ether, polyethylene glycol , the dispersant is preferably 0.005 to 0.05 parts, the...

Embodiment 1

[0045] Add 3000g deionized water, 0.15g dispersant, 0.3g diisopropyl peroxydicarbonate, 1.5g ethyl acetate, 600g VDF monomer, 0.1g α, β, For β-trifluorostyrene monomer, the temperature of the reactor was raised to 60°C for polymerization, and the reaction was terminated after 10 hours. The resulting polymer slurry was filtered and washed and then dried for 10 hours to obtain PVDF resin. After the resin was pressed into tablets, its mechanical properties were measured, and the results are shown in Table 1.

Embodiment 2

[0047] Add 3000g deionized water, 0.3g dispersant, 1.0g tert-butyl peroxypivalate, 3g butyl acetate, 700g VDF monomer, 5g4-bromo-β, For β-difluorostyrene, the temperature of the reactor was raised to 70°C for polymerization, and the reaction was terminated after 8 hours. The resulting polymer slurry was filtered and washed and then dried for 10 hours to obtain PVDF resin. After the resin was pressed into tablets, its mechanical properties were measured, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com