Tensioning-anchoring system and method for prestressed carbon fiber plate of concrete structure

A technology of concrete structure and carbon fiber plate, which is applied in building maintenance, bridge maintenance, bridge reinforcement, etc., can solve the problem of increasing the direct gap between prestressed carbon fiber plate and the reinforced structure, not being able to fully exert active reinforcement, and the effect of tension anchoring is difficult to guarantee to reduce the risk of active reinforcement failure, to achieve reliable anchoring effect, and to improve the effect of anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

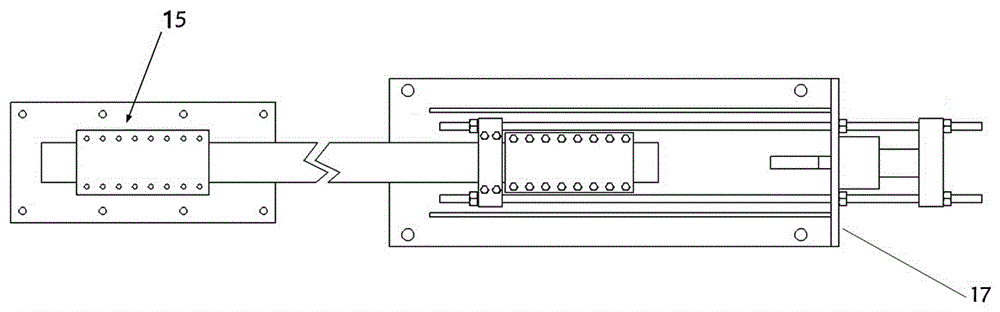

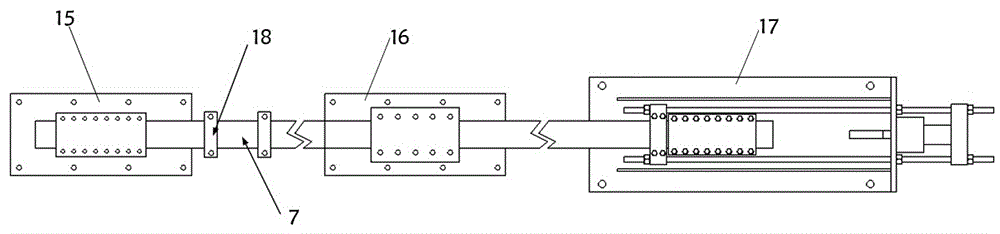

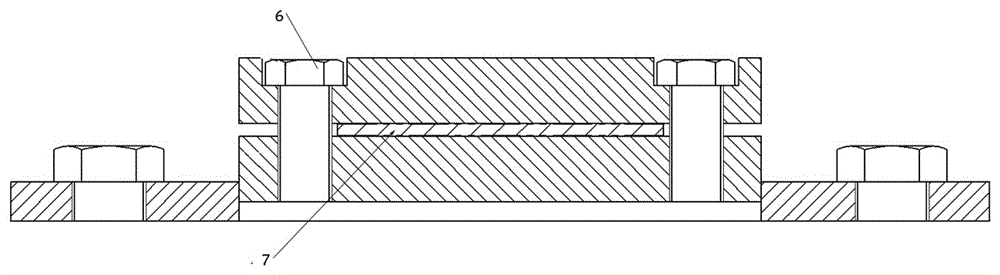

[0041] A tensile anchor system for prestressed carbon fiber panels in concrete structures, including a fixed-end anchor 15, a tension-end anchor 16, and a combined tension device 17;

[0042] The fixed-end anchor 15 and the tension-end anchor 16 both include an upper anchor plate, a lower anchor plate and a base fixedly arranged in sequence from top to bottom, and the base is fixed on the surface of the reinforced structure; the upper anchor plate and A row of compression screw holes are respectively provided on the two long side edges of the lower anchor plate. The upper anchor plate and the lower anchor plate are connected by compression countersunk bolts 6. The part between the tight screw holes is the carbon fiber plate 7 reinforcement area, and the number of the compression countersunk bolts 6 on the anchorage 15 at the fixed end is greater than the number of the countersunk bolts 6 on the anchorage 16 at the tension end;

[0043]The combined tensioning device 17 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com