Biogas pressurizing water-washing device

A technology of pressurized water washing and biogas, which is applied in the direction of gas fuel, petroleum industry, and separation of dispersed particles. It can solve the problems of not providing supporting equipment, high manufacturing cost, and complicated equipment, and achieve improved water washing effect, good uniformity, and The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

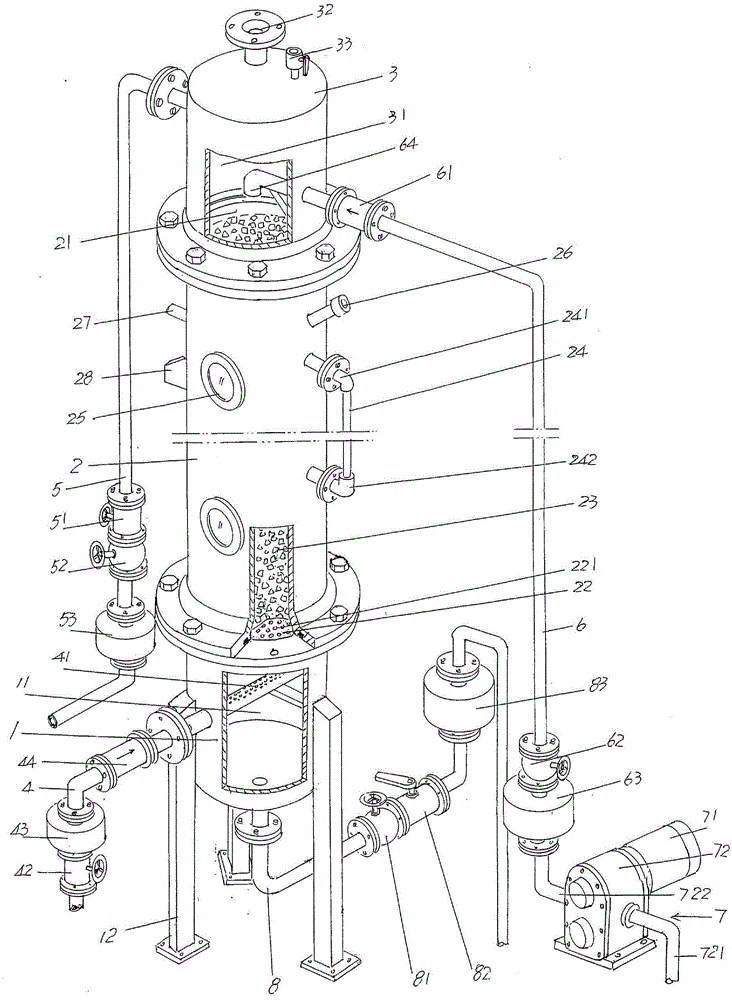

[0017] See figure 1 , shows an air intake tank 1, which is supported on the floor of the place of use in the use state; shows an absorption tower 2, which is fixed to the upper part of the aforementioned air intake tank 1 and The bottom of the absorption tower chamber 21 of the absorption tower 2 is fixed with a packing supporting plate 22, and a through hole 221 is opened in a dense state on the packing supporting plate 22, and the through hole 221 communicates with the air inlet tank cavity 11 of the air inlet tank 1 , packing 23 is arranged in absorption tower cavity 21, and this packing 23 is supported by packing supporting plate 22, and the tower body of absorption tower 2 is provided with liquid level gauge 24, and this liquid level gauge 24 communicates with absorption tower cavity 21; Shown a tower cap 3, this tower cap 3 is fixed with the top of absorption tower 2 and is provided with a safety valve interface 32 that communicates with the tower cap chamber 31 of tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com