Anti-collision board and manufacturing method thereof

An anti-collision board and plate technology, applied in chemical instruments and methods, equipment for preventing bird strikes, lamination, etc., can solve problems such as poor anti-collision and energy-absorbing effect, reduce later maintenance costs, and achieve good anti-collision effect. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

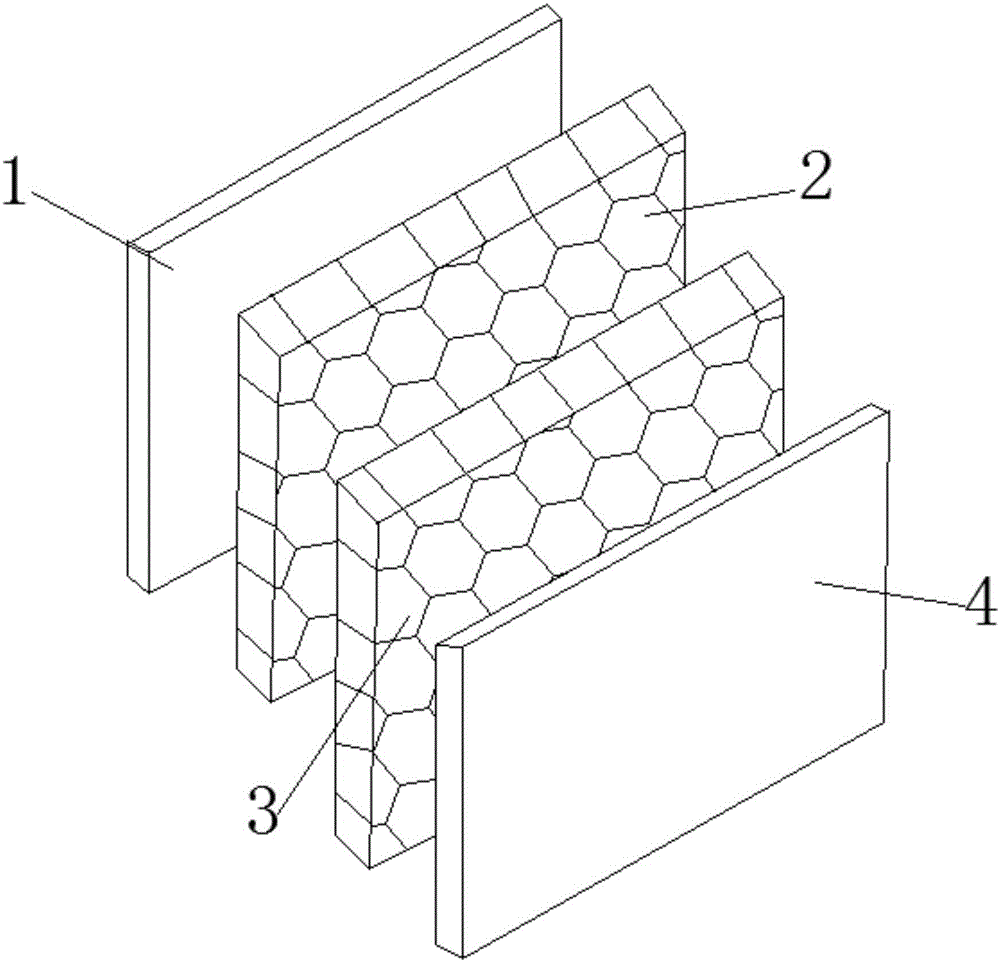

[0024] like figure 1 As shown, the crash board includes an impact layer 1, a buffer layer and an energy-absorbing layer 4, and the impact layer is made of spun fiber. The material of the energy absorbing layer 4 is a high molecular polymer. The buffer layer is a textile honeycomb structure sheet. Between the impact layer 1 and the energy-absorbing layer 4 is a buffer layer, and the buffer layer includes a first spunlace honeycomb layer 2 and a second spunlace honeycomb layer 3 . The thickness of the first textile honeycomb layer 2 is 5 mm, and the thickness of the second textile honeycomb layer 3 is 10 mm. One surface of the first textile honeycomb layer 2 is connected with the impact layer 1 by bisphenol A epoxy resin, and the other surface is connected with one surface of the second textile honeycomb layer 3 by bisphenol A epoxy resin. The other surface of the second textile honeycomb layer 3 is connected to the energy-absorbing layer 4 through bisphenol A epoxy resin, an...

Embodiment 2

[0034] In this example, on the basis of Example 1, the buffer layer is changed to a three-layer structure, and the buffer layer includes a first textile honeycomb layer, a second textile honeycomb layer and a third textile honeycomb layer, and the first textile honeycomb layer. , The second textile honeycomb layer and the third textile honeycomb layer are bonded by functional resin, and the materials of the first textile honeycomb layer, the second textile honeycomb layer and the third textile honeycomb layer are textile honeycomb composite materials. The thickness of the first textile honeycomb layer is 9 mm, the thickness of the second textile honeycomb layer is 10 mm, and the thickness of the third textile honeycomb layer is 8 mm. The other structures are the same as in Example 1. The thickness of the first spun fiber honeycomb layer, the second spun fiber honeycomb layer and the third spun fiber honeycomb layer in this embodiment may be a combination of 5mm-10mm.

[0035]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com