A kind of matting white polyester film and preparation method thereof

A technology of polyester film and light polyester, applied in the field of matte white polyester film and its preparation, can solve the problems of low production cost, secondary pollution, poor adhesion of white matte layer, etc., achieve low production cost, avoid Pollution, Gloss controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

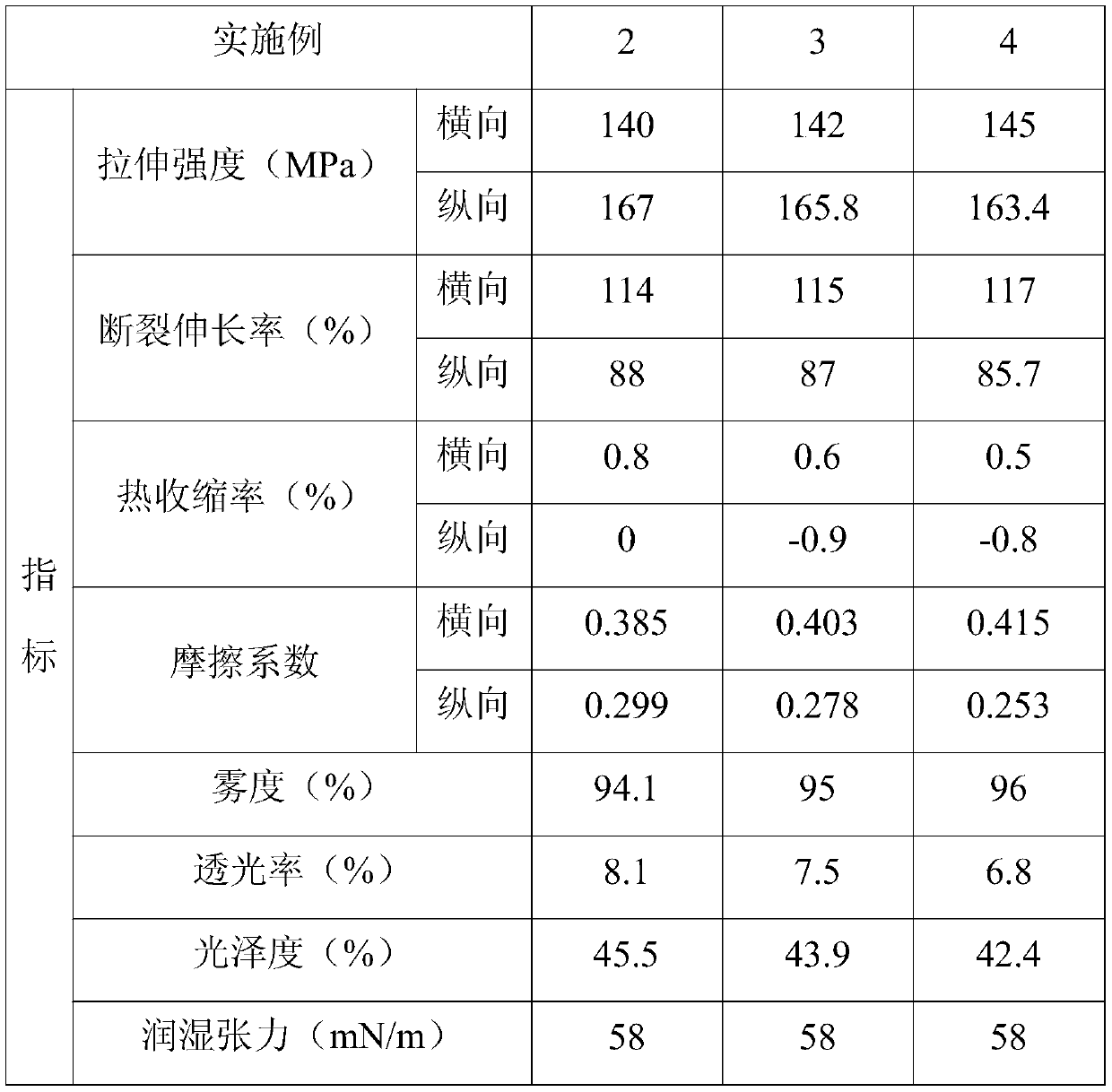

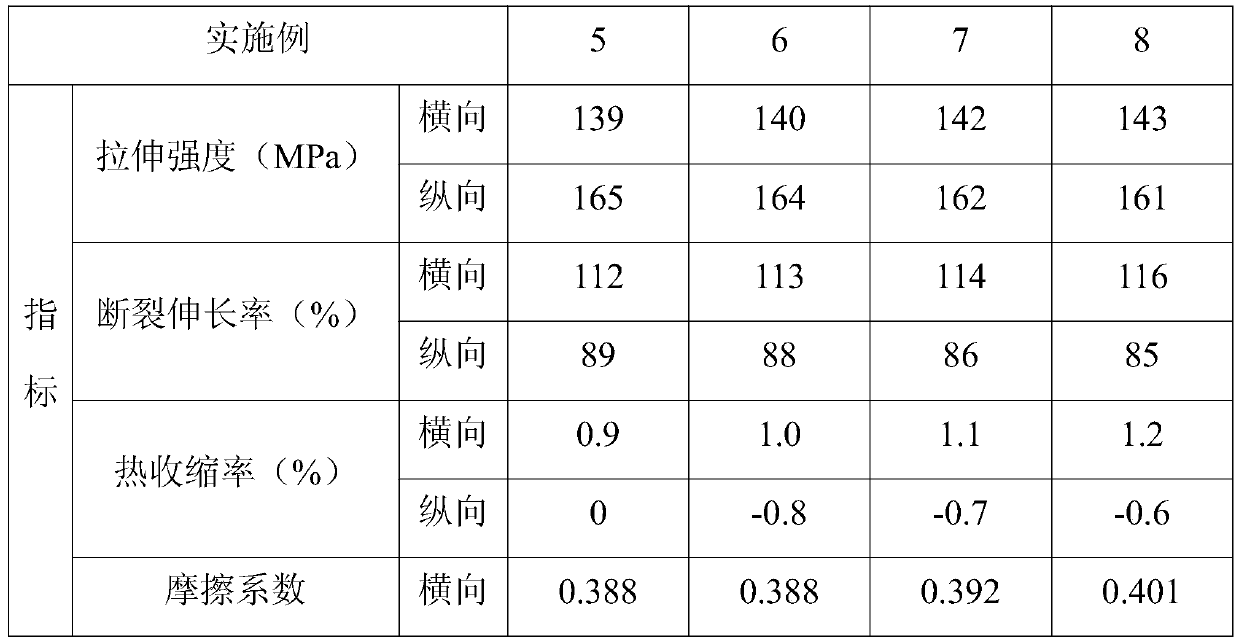

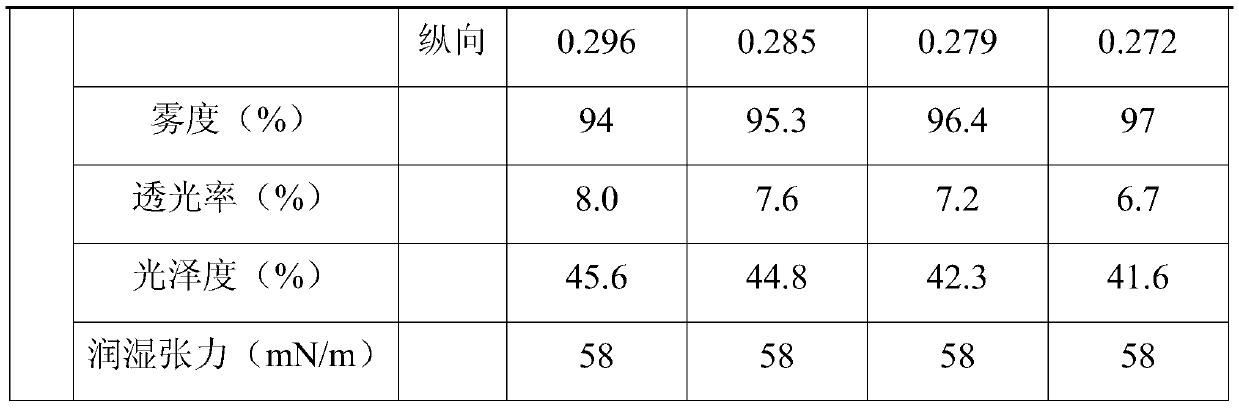

Examples

Embodiment 1

[0023] A matting white polyester film, including ABC three-layer structure, B layer is the middle core layer, the material is super bright polyester chip; A layer is the upper surface white matting layer, the material is matting white masterbatch; C layer is the lower The surface white matting layer is made of matting white masterbatch, which is obtained by melting, blending and granulating polyester chips, silica hollow microspheres, titanium dioxide and silane coupling agent.

[0024] The thickness of layer B accounts for 60%-80%, the thickness of layer A accounts for 10%-20%, and the thickness of layer C accounts for 10%-20%.

[0025] A preparation method for matting white polyester film, comprising the following steps:

[0026] Step 1: First, add polyester chips into a pulverizer to grind polyester powder with a particle size of 200-300nm, and then add polyester powder with a mass percentage of 35% to 50%, polyester powder with a mass percentage of 9% to 15% Silica hollow...

Embodiment 2

[0037] A preparation method for matting white polyester film, comprising the following steps:

[0038] Step 1: First, put the polyester chips into a pulverizer to grind them into polyester powder with a particle size of 200-300nm. The central speed of the pulverizer is 2000r / min, and the motor power is 75KW. According to mass percentage, then add 44.2% polyester powder, 15% silica hollow microspheres, 40% titanium dioxide, 0.8% HK570 silane coupling agent into the mixer, first at a speed of 2500r / min Mix the materials for 13 minutes, then adjust the speed to 20r / min, and mix the materials for 2 minutes. Finally, add the mixed raw materials into the extruder, and melt and extrude them at 250°C to 280°C to prepare a matte white masterbatch;

[0039] Step 2: Add the matte white masterbatch prepared in step 1 to the auxiliary twin-screw extruder for extrusion (layer A); the main extruder (layer B ) is 100% super-bright polyester chip according to the mass percentage, and the raw ...

Embodiment 3

[0045] The difference between this embodiment and embodiment 2 is that the mass ratio of the extruded material from the main extruder and two auxiliary twin-screw extruders is 15:65:20, the thickness of the white matting layer of the film A layer of 50um is 7.5um, and the thickness of the C layer is 7.5um. The thickness of the white matting layer is 10um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com