Automatic control system for metal binding machine and control method

An automatic control system and strapping machine technology, which is applied in the directions of automatic packaging control, strapping machine parts, strapping materials, etc., can solve the problems of packaging control accuracy and production efficiency, and achieve the effect of large market development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

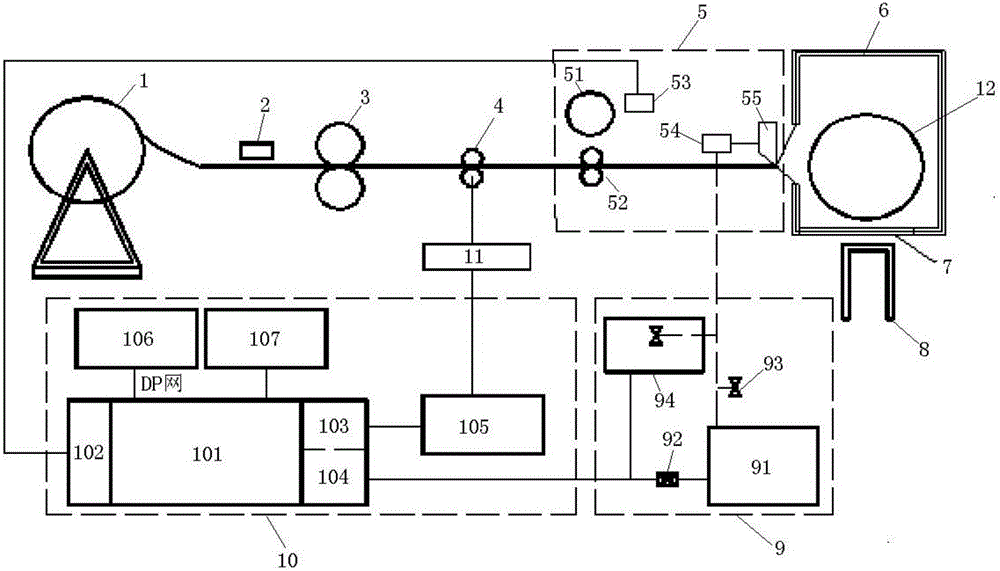

[0037] like figure 1 As shown, an automatic control system for a metal strapping machine, the metal strapping machine is a steel strap strapping machine, and its mechanical system consists of a strap distributor 1, a guiding device 2, a leveling machine 3, and a moving Frame 4, strapping machine head 5 and guide groove 6 are made up; The control system of this metal strapping machine comprises electrical control system 10 and pneumatic control system 9, and wherein electrical control system 10 is made up of main controller 101 and main controller 101 respectively. The connected touch screen 106, signal detection unit 102, speed control unit 103, pneumatic control unit 104 and emergency stop unit 107 are composed, and the speed control unit 103 is connected to the control end of the mobile frame 4 through the frequency converter 105 and the frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com