Carbon nanotube purification system for removing metal ions

A carbon nanotube, metal ion technology, applied in the direction of carbon nanotubes, nanocarbons, etc., can solve problems such as unfavorable mass production applications, no introduction and separation of strong oxidizing acid impurities, etc., to avoid industrial heat energy waste and increase heat exchange efficiency. , the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

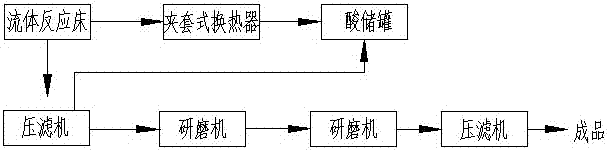

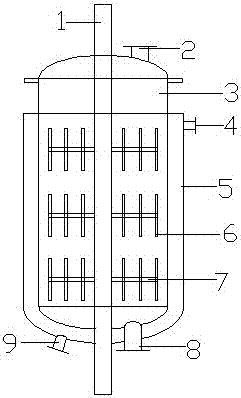

[0032] figure 1 It is a schematic diagram of the connection relationship of the present invention. It can be seen in conjunction with the accompanying drawings that the carbon nanotube purification system for removing metal ions includes a fluid reaction bed, a heat exchanger, an acid storage tank, two grinders and two filter presses. The fluid reaction bed is used for the place where carbon nanotube raw material powder and acid liquid react, the heat exchanger is used to cool the acid gas produced by the fluid reaction bed, and the acid storage tank is used to store the acid solution cooled by the heat exchanger and The acid solution extruded by the filter press is used for extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com