Method for preparing sea urchin shaped titanium dioxide hollow microsphere

A technology of titanium dioxide and hollow microspheres, applied in the direction of titanium dioxide, titanium oxide/hydroxide, hybrid capacitor electrodes, etc., can solve the problems of complex electrode film preparation procedures, achieve excellent photoelectric conversion performance, the method is simple and easy to operate, and has wide application Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

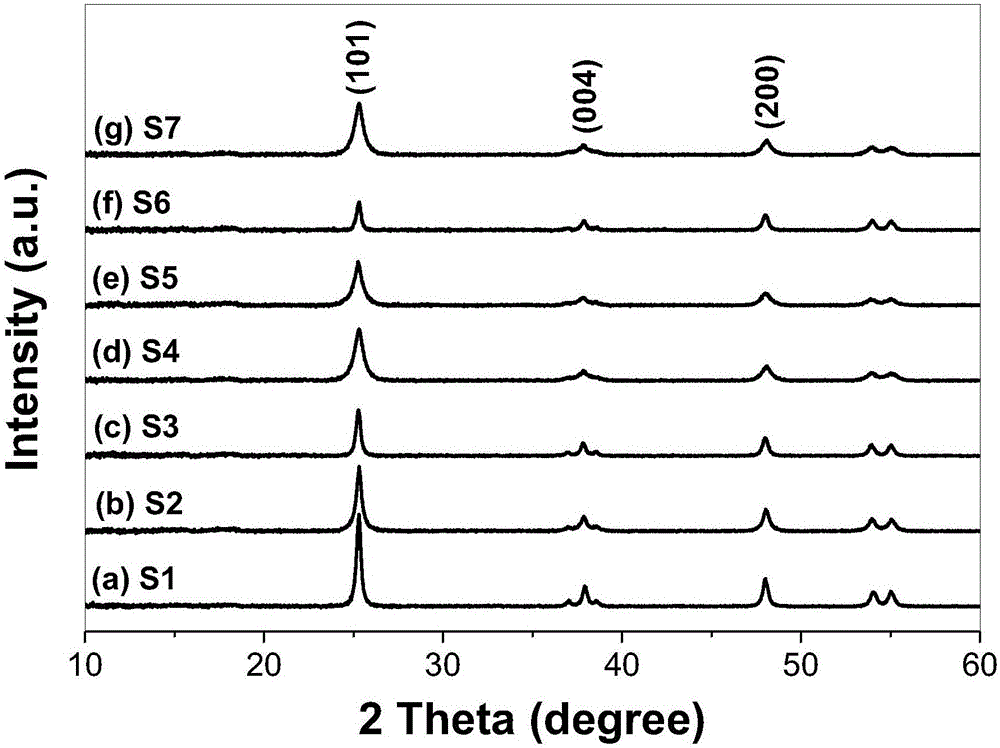

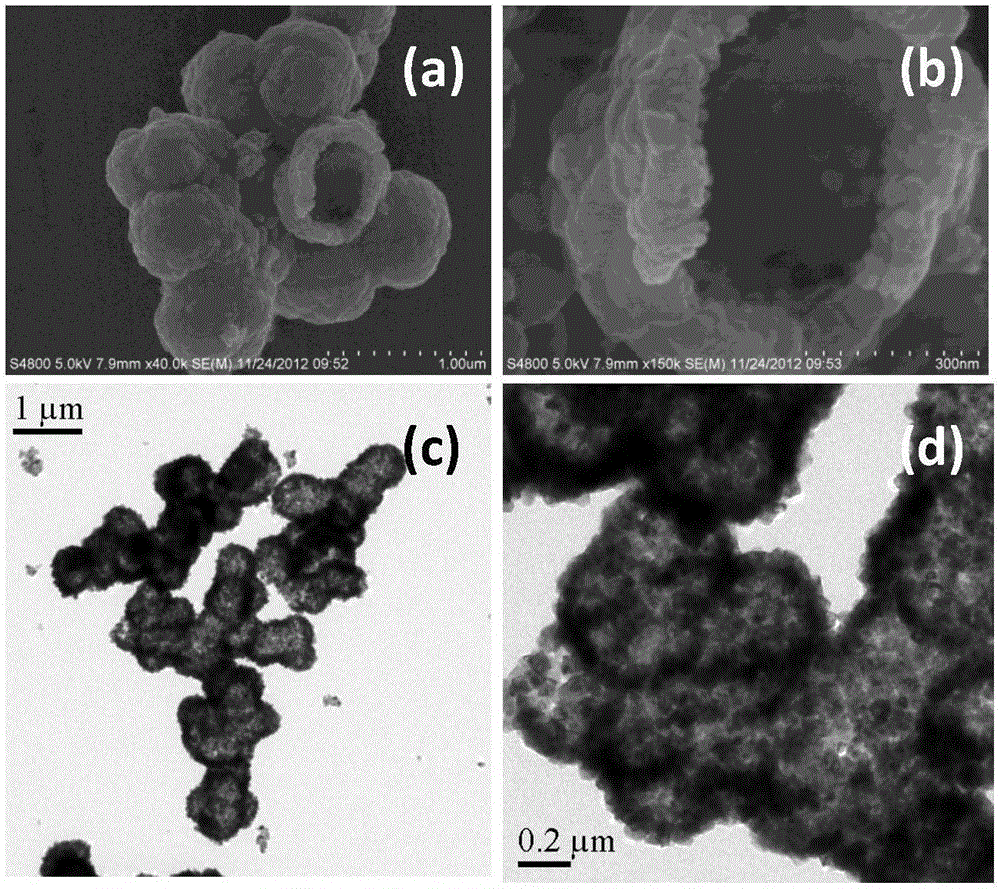

Embodiment 1

[0038] 1) Add 0.5g of titanium dioxide hollow microspheres (see Comparative Example 1 for the synthesis method) into 50ml of 10mol / L NaOH solution, stir and disperse for 10min, then transfer to a polytetrafluoroethylene reactor (with stainless steel lining);

[0039] 2) Seal the polytetrafluoroethylene reactor and place it in an oven, heat it to 120°C, and keep it warm for 1 hour. After the reaction is completed, naturally cool the polytetrafluoroethylene reactor to room temperature (20-30°C), and put the reaction The resulting mixed system was filtered to obtain filter residue A, which was washed with distilled water to neutrality (pH=7), and dried naturally;

[0040] 3) Add 600 ml of 0.1 mol / L dilute hydrochloric acid to the filter residue A that was naturally dried in step 2), and after magnetic stirring for 12 hours, filter to obtain filter residue B, and wash filter residue B with distilled water until neutral (pH=7) , to dry naturally;

[0041] 4) Put the naturally-drie...

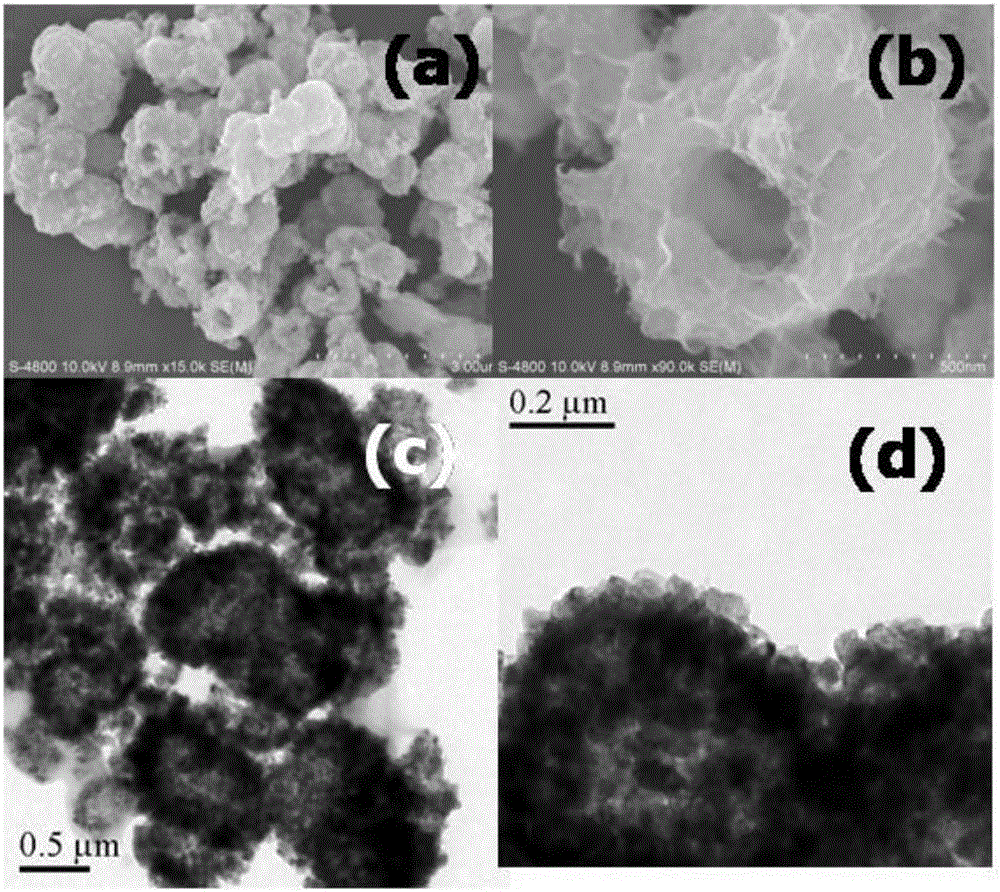

Embodiment 2

[0045] 1) Add 0.5g of titanium dioxide hollow microspheres (see Comparative Example 1 for the synthesis method) into 50ml of 10mol / L NaOH solution, stir and disperse for 10min, then transfer to a polytetrafluoroethylene reactor (with stainless steel lining);

[0046] 2) Seal the polytetrafluoroethylene reactor and put it in an oven, heat it to 120°C, and keep it warm for 2 hours. After the reaction is completed, naturally cool the polytetrafluoroethylene reactor to room temperature (20-30°C), and put the reaction The resulting mixed system was filtered to obtain filter residue A, which was washed with distilled water to neutrality (pH=7), and dried naturally;

[0047] 3) Add the naturally-dried filter residue A in step 2) into 600ml of 0.1mol / L hydrochloric acid, and after magnetic stirring for 12 hours, filter to obtain the filter residue B, which is washed with distilled water until neutral (pH=7), dry naturally;

[0048] 4) Put the naturally-dried filter residue B in step ...

Embodiment 3

[0052] 1) Add 0.5g of titanium dioxide hollow microspheres (see Comparative Example 1 for the synthesis method) into 50ml of 10mol / L NaOH solution, stir and disperse for 10min, then transfer to a polytetrafluoroethylene reactor (with stainless steel lining);

[0053] 2) Seal the polytetrafluoroethylene reactor and place it in an oven, heat it to 120°C, and keep it warm for 3 hours. After the reaction is completed, naturally cool the polytetrafluoroethylene reactor to room temperature (20-30°C), and put the reaction The resulting mixed system was filtered to obtain filter residue A, which was washed with distilled water to neutrality (pH=7), and dried naturally;

[0054] 3) Add 600 ml of 0.1 mol / L dilute hydrochloric acid to the filter residue A that was naturally dried in step 2), and after magnetic stirring for 12 hours, filter to obtain filter residue B, and wash filter residue B with distilled water until neutral (pH=7) , to dry naturally;

[0055] 4) Put the naturally-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com