Coagulation-accelerating early strength agent for 3D printing house slurry

A coagulation-accelerating early-strength and 3D printing technology, which is applied in the field of coagulation-accelerating early-strength agents to achieve the effect of promoting slurry coagulation, rapid hardening, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

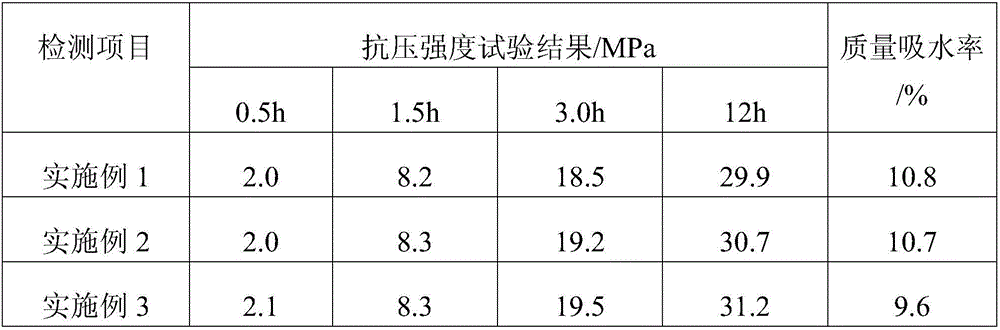

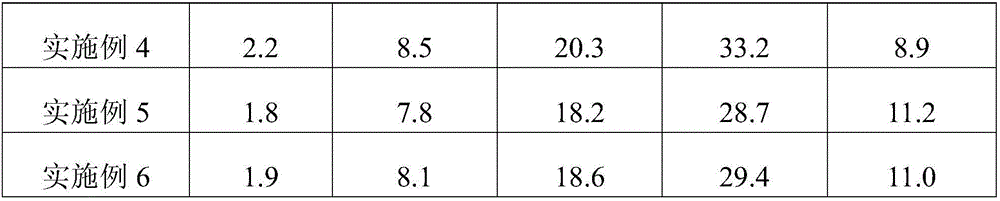

Examples

Embodiment 1

[0019] A coagulation accelerator for 3D printing house slurry, with kg as the unit, weigh the required raw materials for each component: 50 kg of anhydrous sodium sulfate, 1 kg of calcium nitrite, 5 kg of aluminum sulfate, 5 kg of humic acid, guar 0.1kg of glue, 5kg of 3-[(2,4-dichloro)phenyl]-2-acrylic acid, 10kg of filler zinc oxide and 1kg of additives; among them, the additives consist of 10kg of pond mud, 10kg of starch syrup, 5kg of anhydrous copper sulfate and The natural polymer material agar is composed of 11kg; the raw materials of each component obtained by weighing the above are mixed and stirred evenly.

Embodiment 2

[0021] A coagulation accelerator and early strength agent for 3D printing house slurry, with kg as the unit, weigh the required raw materials for each component: anhydrous sodium sulfate 100kg, calcium nitrite 7kg, aluminum sulfate 7kg, humic acid 10kg, guar 0.3kg of glue, 7kg of 3-[(2,4-dichloro)phenyl]-2-acrylic acid, 20kg of filler antimony trioxide and 3kg of additives; among them, the additives consist of 30kg of pond mud, 16kg of starch syrup, anhydrous copper sulfate 9kg and 18kg of natural polymer potato starch; among them, the potato starch is obtained by drying fresh potatoes at 70-80°C for 5-10 minutes and grinding them into powder; mix the above-mentioned raw materials of each component obtained by weighing, and stir evenly. .

Embodiment 3

[0023] A coagulation accelerator and early strength agent for 3D printing house slurry, with kg as the unit, weigh the required raw materials for each component: 75kg of anhydrous sodium sulfate, 4kg of calcium nitrite, 6kg of aluminum sulfate, 7kg of humic acid, guar 0.2kg of glue, 6kg of 3-[(2,4-dichloro)phenyl]-2-acrylic acid, 15kg of filler titanium dioxide and 2kg of additives; among them, the additives consist of 20kg of pond mud, 13kg of starch syrup, 7kg of anhydrous copper sulfate and natural The polymer material lignin is composed of 15kg; the raw materials of each component obtained by weighing the above are mixed and stirred evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com