Method for preparing triptorelin acetate through specific microwave synthesis

A technology of triptorelin acetate and microwave synthesis, which is applied in the field of synthesis and preparation of polypeptide drugs, can solve the problems of only triptorelin total yield, unfavorable large-scale production, complicated purification methods, etc., and achieve simplified process flow and efficient Good for mass production and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

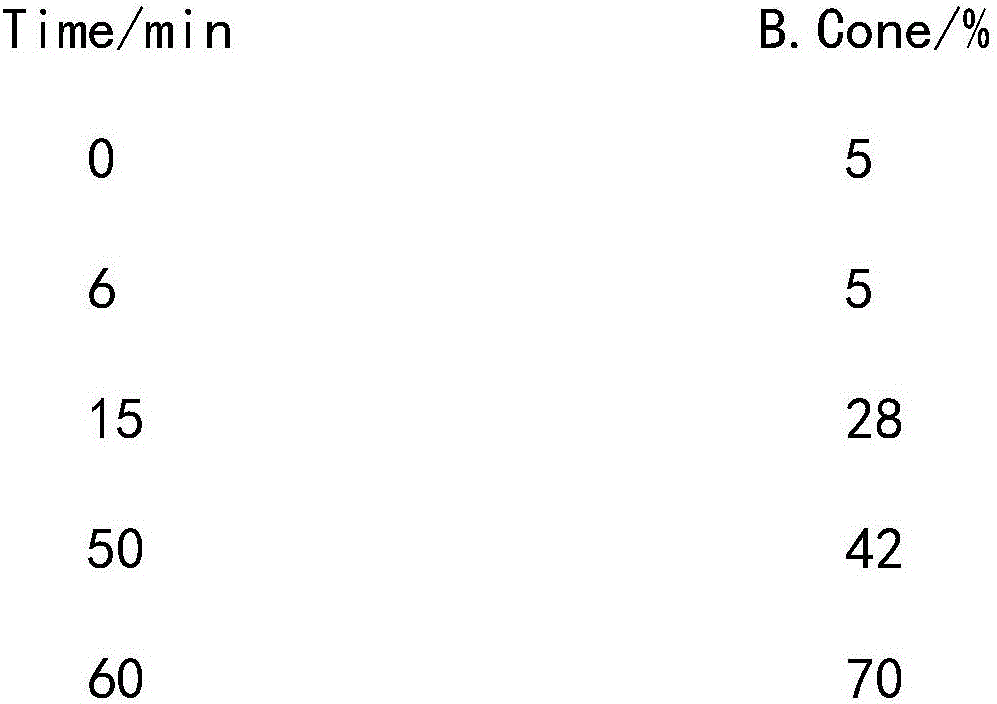

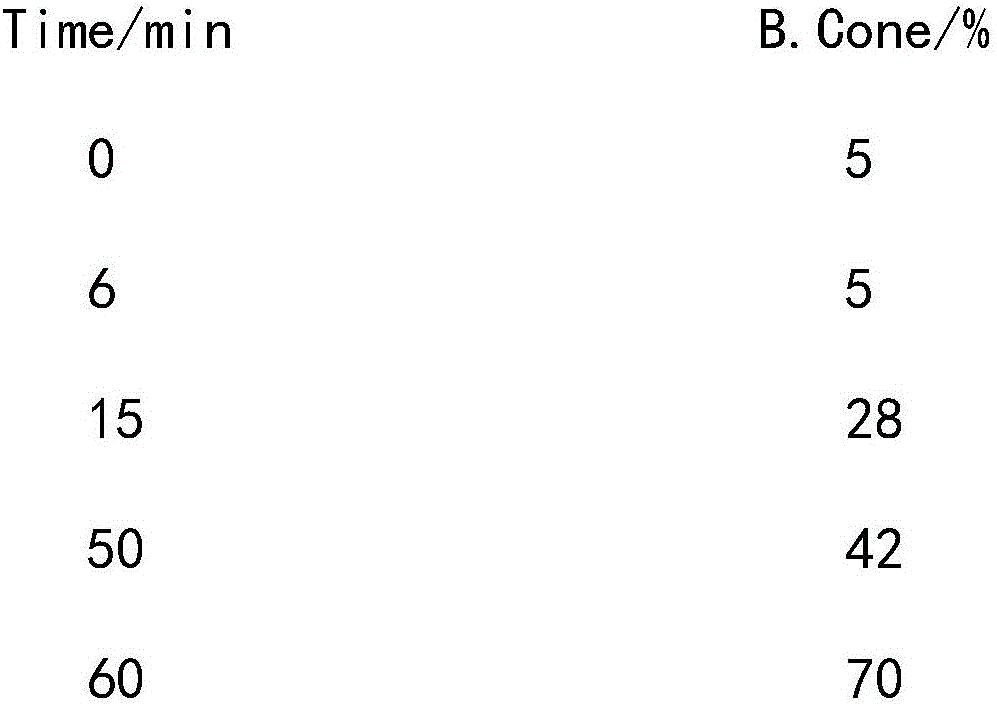

[0035] Embodiment 1: the method that specific microwave synthesis prepares triptorelin acetate, operation steps are as follows:

[0036] (1): Preparation of the target amino resin of the starting resin carrier

[0037] Add 0.1 g of Rink Amide-AM Resin amino resin with a substitution degree of 0.38mmol / g into the polypeptide synthesis reactor from the open end, take the DCM reagent and add it to the reactor, so that the resin is completely immersed in the DCM solvent, and the solvent Full contact, swelling for 2 hours;

[0038] After the amino resin solution is drained, add 1 / 3 of the reactor volume of 20% piperidine and DMF mixed solution, place on a 30r / min decolorizing shaker and shake for 20min, then use a vacuum pump to drain the deprotection solution; Add 1 / 3 of the DMF solution of the reactor volume, place it on a decolorizing shaker and shake for 1 min, drain the solution with a vacuum pump, add DMF solution again to wash the resin, and repeat the operation twice; use ...

Embodiment 2

[0058] (1): Preparation of the target amino resin of the starting resin carrier

[0059] Add 2 g of Rink Amide-AM Resin amino resin with a degree of substitution of 0.45 mmol / g into the polypeptide synthesis reactor from the open end, take the DCM reagent and add it to the reactor, so that the resin is completely immersed in the DCM solvent, fully mixed with the solvent Contact, swelling for 8h;

[0060] After the amino resin solution is drained, add 1 / 2 of the reactor volume of 20% piperidine and DMF mixed solution, place on a 30r / min decolorizing shaker and shake for 20min, then use a vacuum pump to drain the deprotection solution; Add DMF solution of 1 / 2 the volume of the reactor, place it on a decolorizing shaker and shake for 90s, drain the solution with a vacuum pump, add DMF solution again to wash the resin, repeat the operation twice, use ninhydrin for color detection, and obtain target amino resin;

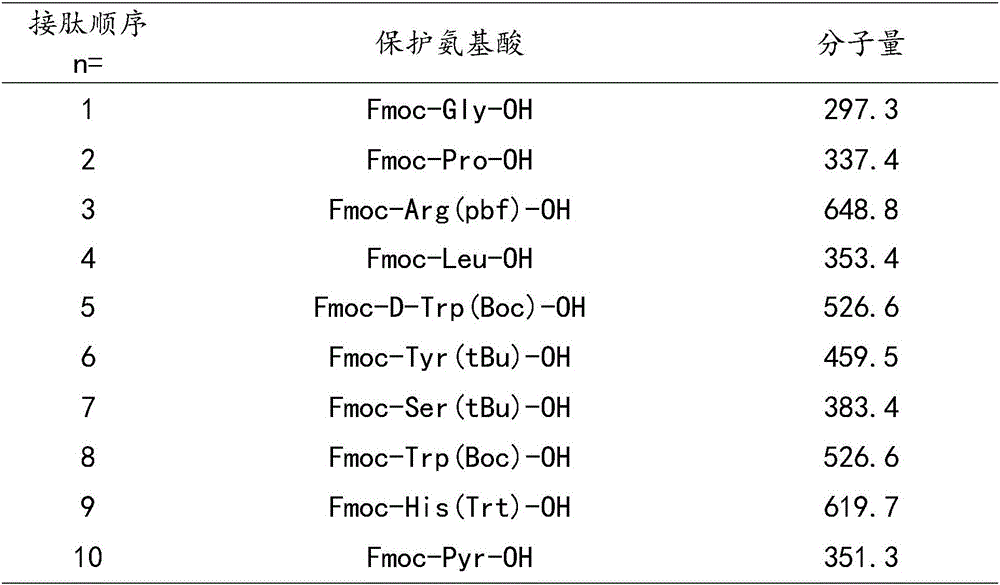

[0061] (2): Preparation of protected amino acids

[0062] Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com