Nitrile rubber-compounded fluororesin multi-layer fuel rubber pipe

A technology of nitrile rubber and fuel hose, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., which can solve the problems of poor barrier performance of fuel hoses and poor overall performance of hoses, and achieve good oil resistance, improve weather resistance, and improve structure holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0051] Using butyl rubber with 34% acrylonitrile as raw material, two-component adhesive 1 and two-component adhesive 2 are two-component adhesives of Russian Red Star Chemical, and ether ester ABD-30 is used as raw material. The raw material is ether ester, and the cross-linking agent TAC is the cross-linking agent; and the appropriate amount of each raw material is weighed according to the raw material ratio shown in the following table to obtain the nitrile rubber material formula of Example 1-5:

[0052] Table 1 Example 1-5 Nitrile rubber material formula

[0053]

[0054] Then, the nitrile rubber composite fluororesin multilayer fuel hose of Example 1-5 was prepared according to the steps shown below, and the specific preparation steps are as follows:

[0055] (1) After mixing the nitrile rubber compositions described in Examples 1-5 separately, perform the first stage mixing at 110-140°C, and then perform the second stage mixing at 90-120°C, The nitrile rubber material of Exam...

experiment example 1

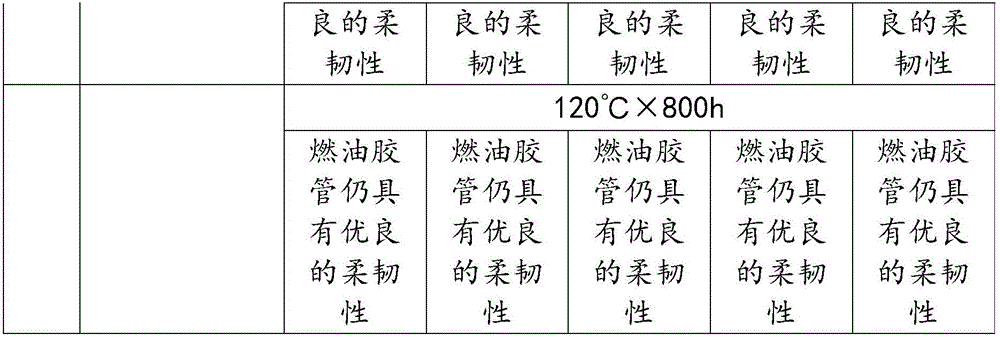

[0063] Performance tests were performed on the nitrile rubber composite fluororesin multilayer fuel hoses obtained in Examples 1-5, and the test results are shown in Table 2 below:

[0064] Table 2 Performance test results of multilayer fuel hoses of nitrile rubber composite fluororesin in Examples 1-5

[0065]

[0066]

experiment example 2

[0073] Performance tests were performed on the nitrile rubber composite fluororesin multilayer fuel hoses obtained in Comparative Examples 1-3. The test results are shown in Table 2 below:

[0074] Table 2 Performance test results of multilayer fuel hose of comparative example 1-3 nitrile rubber composite fluororesin

[0075]

[0076] In the present invention, by adjusting the types and amounts of plasticizers, vulcanizing agents and adhesives used in the nitrile rubber raw materials, the nitrile rubber of the present invention can have good oil resistance, high temperature resistance and low temperature aging performance; at the same time, It also makes the nitrile rubber prepared by the present invention have good adhesion properties, and can have good adhesion with the fluororesin rubber layer and the reinforcing layer and the protective layer materials of the outer layer, and it also improves the further prepared The structural integrity of the fuel hose;

[0077] At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com