Preparation process of phthalocyanine blue for PU inkjet printing

A preparation process, phthalocyanine blue technology, applied in the field of pigment processing, can solve the problems of environmental pollution, loss of fluidity, low yield, etc., and achieve the effect of huge market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

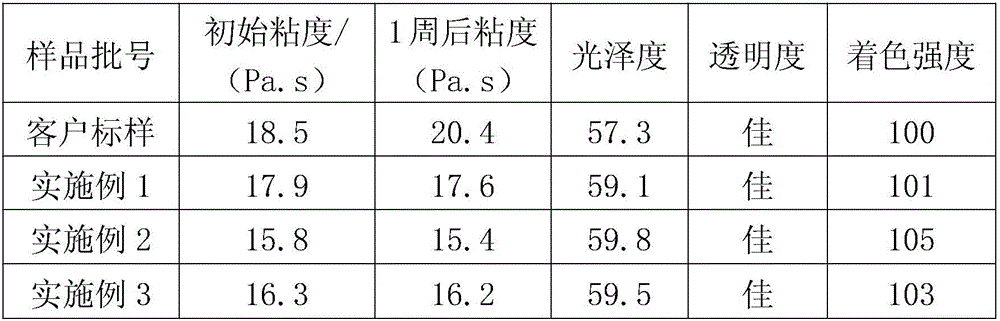

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of phthalocyanine blue

[0018] 1) Put 600kg of anhydrous sodium sulfate and 900kg of copper phthalocyanine into a 15,000L horizontal ball mill, grind at 75°C for 20 hours, beat the pulp, boil with acid to remove iron, then reflux with tetrahydrofuran solvent for 3 hours, distill off the solvent, press filter, Wash with water until the conductivity is less than 300μs / cm, and the unloaded filter cake is crude phthalocyanine blue;

[0019] 2) Under stirring conditions, put 6000kg of concentrated sulfuric acid with a concentration of 101% into the reaction kettle, slowly put in 700kg of copper phthalocyanine at 40°C, raise the temperature to 70°C at a speed of 3-5°C / min, keep it warm for 2h, and then Add 8t of water, 260kg of C14 alkyl trimethyl ammonium chloride, 60 kg of C18 dialkyl dimethyl ammonium chloride, heat up to 50°C, keep warm, and reach the end of sulfonation when the measured absorbance is 0.5, turn on the circulating cooling wat...

Embodiment 2

[0021] Embodiment 2: the preparation of phthalocyanine blue

[0022] 1) Put 600kg of anhydrous sodium sulfate and 1800kg of copper phthalocyanine into a 15,000L horizontal ball mill, grind at 60°C for 8 hours, beat the pulp, boil with acid to remove iron, then reflux with THF solvent for 2.5h, distill off the solvent, and press filter , washed with water until the conductivity is less than 300μs / cm, and the unloaded filter cake is crude phthalocyanine blue;

[0023] 2) Under stirring conditions, put 6000kg of concentrated sulfuric acid with a concentration of 102% into the reactor, slowly drop in 800kg of copper phthalocyanine at 35°C, heat up to 80°C at a speed of 3-5°C / min, and keep the temperature for 2.5h. Add 6t of water, 230kg of C14 alkyltrimethylammonium chloride, and 65kg of C20 dialkyldimethylammonium chloride in sequence, raise the temperature to 55°C, keep it warm, and reach the end of sulfonation when the measured absorbance is 0.5, and turn on the circulation coo...

Embodiment 3

[0025] Embodiment 3: the preparation of phthalocyanine blue

[0026] 1) Put 600kg of anhydrous sodium sulfate and 1500kg of copper phthalocyanine into a 15,000L horizontal ball mill, grind at 80°C for 30 hours, beat the pulp, boil with acid to remove iron, then reflux with tetrahydrofuran solvent for 2 hours, distill off the solvent, press filter, Wash with water until the conductivity is less than 300μs / cm, and the unloaded filter cake is crude phthalocyanine blue;

[0027] 2) Under stirring conditions, put 6000kg of concentrated sulfuric acid with a concentration of 105% into the reaction kettle, slowly put in 500kg of copper phthalocyanine at 30°C, raise the temperature to 70°C at a speed of 3-5°C / min, keep it warm for 2h, and then Add 5t of water, 290kg of C14 alkyl trimethyl ammonium chloride, 55 kg of C18 dialkyl dimethyl ammonium chloride, raise the temperature to 50°C, keep it warm, and reach the end of sulfonation when the measured absorbance is 0.5, turn on the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com