Preparation method of atomic flat Sr/Si(100)-(2 * 3) reconstruction surface

An atomic-level, flat technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of reducing the dielectric properties of high dielectric constant oxides and unable to realize epitaxial growth of high dielectric constant oxides and other problems to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

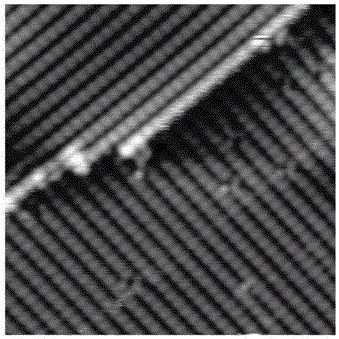

Image

Examples

Embodiment 1

[0041] A method for preparing an atomically flat Sr / Si(100)-2×3 reconstructed surface in this embodiment uses a single crystal silicon (100) sheet as a substrate, and the steps are as follows:

[0042] 1) Substrate cleaning:

[0043] 1-1) Cut the single crystal silicon (100) piece into a certain size, in this embodiment, the single crystal silicon (100) piece is cut into 2×2cm 2 size;

[0044] 1-2) ultrasonically clean the cut monocrystalline silicon (100) slices in acetone. In this embodiment, the single crystal silicon (100) slices are ultrasonically cleaned in acetone for 3 times, and the time for each ultrasonic cleaning is 15 minutes;

[0045] 1-3) The monocrystalline silicon (100) slices ultrasonically cleaned with acetone were cleaned with pure water. The time is 10 minutes;

[0046] 1-4) Blow dry the monocrystalline silicon (100) sheet after ultrasonic cleaning with pure water with high-purity nitrogen, and then put it into a vacuum chamber;

[0047] 2) Remove the si...

Embodiment 2

[0062] A method for preparing an atomically flat Sr / Si(100)-2×3 reconstructed surface in this embodiment uses a single crystal silicon (100) sheet as a substrate, and the steps are as follows:

[0063] 1) Substrate cleaning:

[0064] 1-1) Cut the single crystal silicon (100) piece into a certain size, in this embodiment, the single crystal silicon (100) piece is cut into 2×2cm 2 size;

[0065] 1-2) ultrasonically clean the cut monocrystalline silicon (100) slices in acetone. In this embodiment, the single crystal silicon (100) slices are ultrasonically cleaned in acetone for 3 times, and the time for each ultrasonic cleaning is 15 minutes;

[0066] 1-3) The monocrystalline silicon (100) slices ultrasonically cleaned with acetone were cleaned with pure water. The time is 10 minutes;

[0067] 1-4) Blow dry the monocrystalline silicon (100) sheet after ultrasonic cleaning with pure water with high-purity nitrogen, and then put it into a vacuum chamber;

[0068] 2) Remove the ...

Embodiment 3

[0082] A method for preparing an atomically flat Sr / Si(100)-2×3 reconstructed surface in this embodiment uses a single crystal silicon (100) sheet as a substrate, and the steps are as follows:

[0083] 1) Substrate cleaning:

[0084] 1-1) Cut the single crystal silicon (100) piece into a certain size, in this embodiment, the single crystal silicon (100) piece is cut into 2×2cm 2 size;

[0085] 1-2) ultrasonically clean the cut monocrystalline silicon (100) slices in acetone. In this embodiment, the single crystal silicon (100) slices are ultrasonically cleaned in acetone for 3 times, and the time for each ultrasonic cleaning is 15 minutes;

[0086] 1-3) The monocrystalline silicon (100) slices ultrasonically cleaned with acetone were cleaned with pure water. The time is 10 minutes;

[0087] 1-4) Blow dry the monocrystalline silicon (100) sheet after ultrasonic cleaning with pure water with high-purity nitrogen, and then put it into a vacuum chamber;

[0088] 2) Remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com