Messy fluff recovery device for spinning

A recovery device and fluff technology, which is applied in textiles and papermaking, fiber treatment, fiber separation, etc., can solve problems affecting product quality control, unsatisfactory recycling effect, and inability to use mixed fluff, so as to achieve good promotion and utilization value and save energy. Equipment cost, effect of increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following describes the embodiments of the present invention with reference to the accompanying drawings, and the embodiments do not constitute a limitation to the present invention:

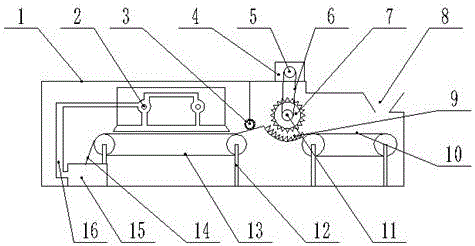

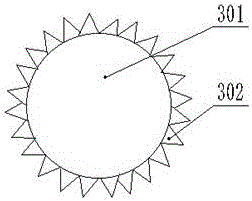

[0018] Such as figure 1 , figure 2 As shown, the structure of this kind of textile miscellaneous fluff recovery device for textiles includes a box body 1. The upper right side of the box body 1 is provided with a feed port 8, and the lower end of the feed port 8 is provided with a right conveyor belt 10, The left side of the conveyor belt 10 is provided with stirring teeth 9 and the upper end of the stirring teeth 9 is provided with a stirring roller 7, and the front end of the stirring roller 7 is provided with a large pulley 11, which is connected to a small pulley on the motor 4 through a belt 6 5 Connected. Therefore, when in use, the box 1 prevents external dust from entering the interior, thereby affecting the normal operation of the internal device. The down and feathers enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com