Tensioner

A technology of tensioning device and sleeve, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of wear, sintering, the sliding property of plunger 540, the adverse effect of attenuation characteristics, etc., and reduce the required accuracy , The effect of avoiding the increase of the processing burden and reducing the work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a tension device 10 according to an embodiment of the present invention will be described with reference to the drawings.

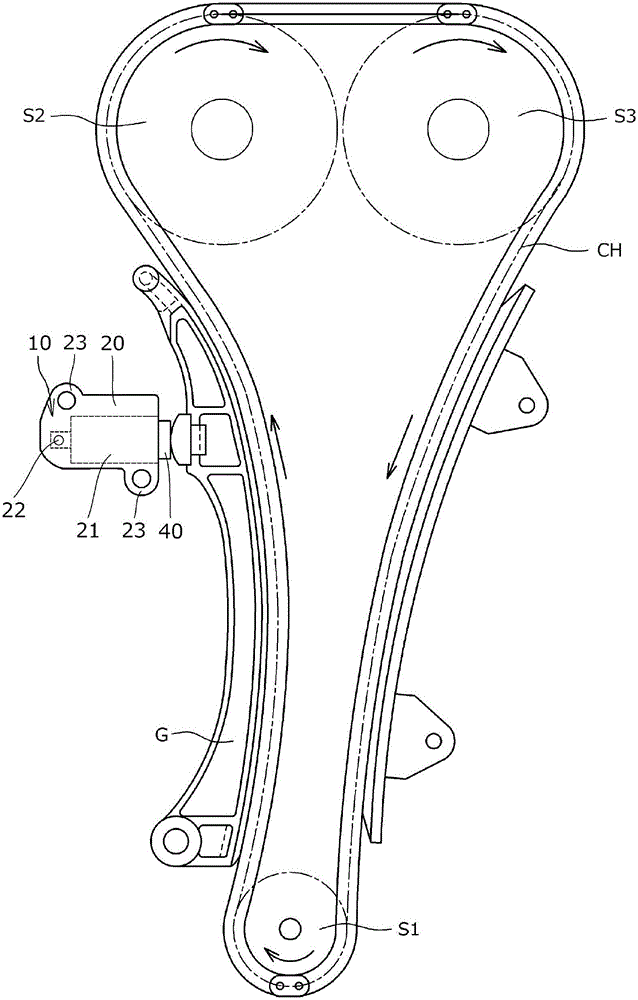

[0030] First, the tensioner 10 of the present embodiment is mounted on a chain transmission used in a timing system of an automobile engine, etc., such as figure 1 As shown, it is installed on the engine body (not shown), and through the tensioner rod G, an appropriate tension is applied to the slack side of the transmission chain CH that is rotatable on the multiple sprockets S1-S3, and the vibration during movement is suppressed. .

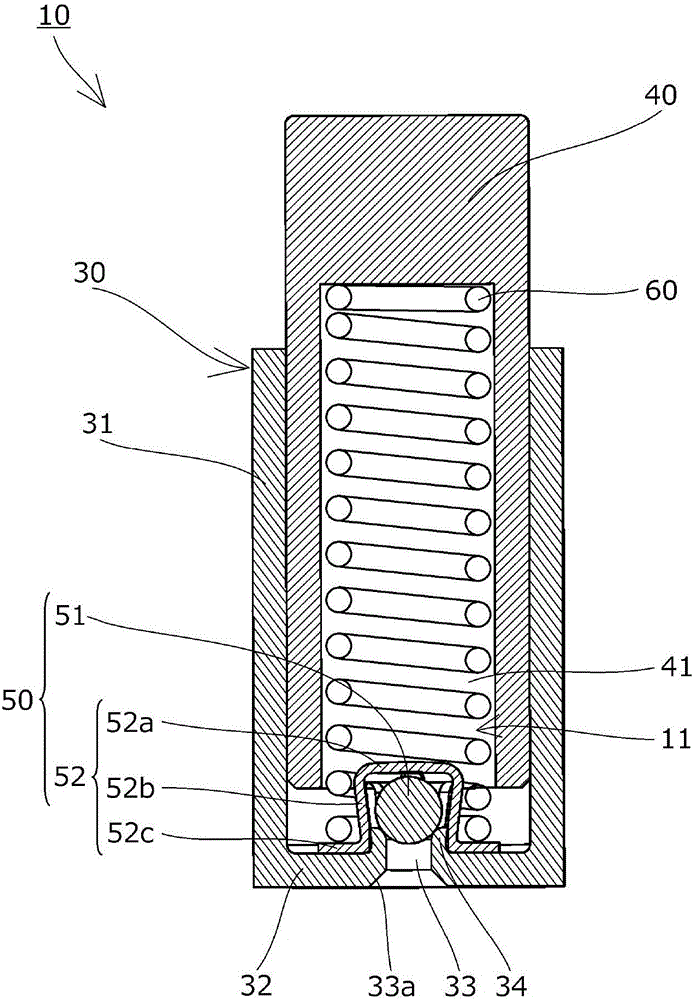

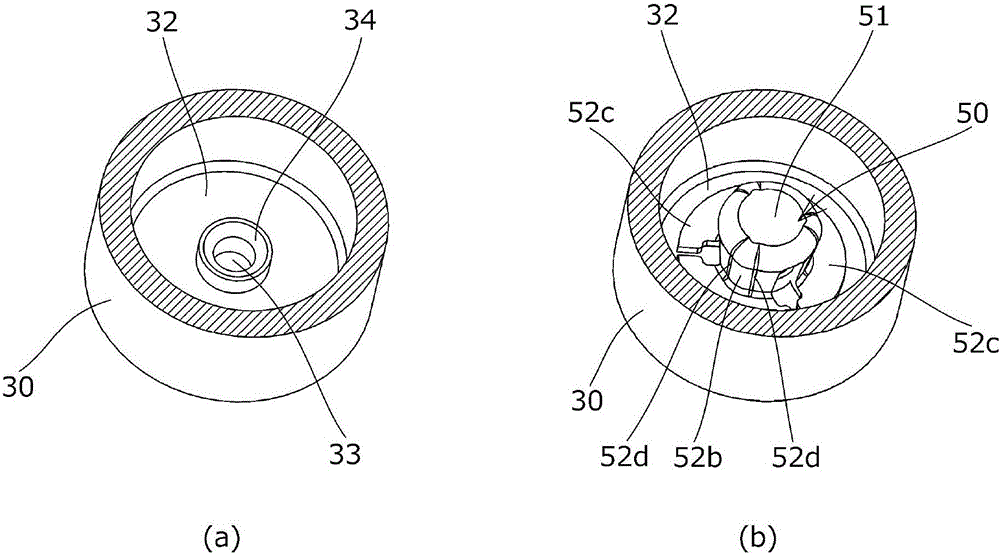

[0031] Such as Figure 1 ~ Figure 3 As shown, the tensioning device 10 is provided with: a tensioning device main body 20 having a main body hole 21; a sleeve 30 inserted into the main body hole 21; Inside the sleeve 30 ; the check valve 50 ; and the coil spring 60 as an urging unit are freely accommodated in the pressure oil chamber 11 formed between the rear end side of the sleeve 30 and the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com