Intelligent calculating prediction control method of thermal power generating unit coordination control system

A coordinated control system and predictive control technology, applied in general control systems, control/adjustment systems, adaptive control, etc., can solve problems such as inability to reflect, deviate from the characteristics of the coordinated system, and control effects that cannot meet the control quality, so as to improve dynamic performance. Adjust performance and stability, program for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

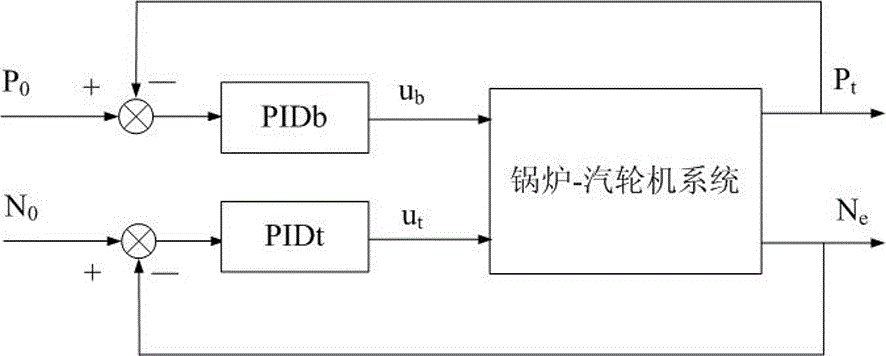

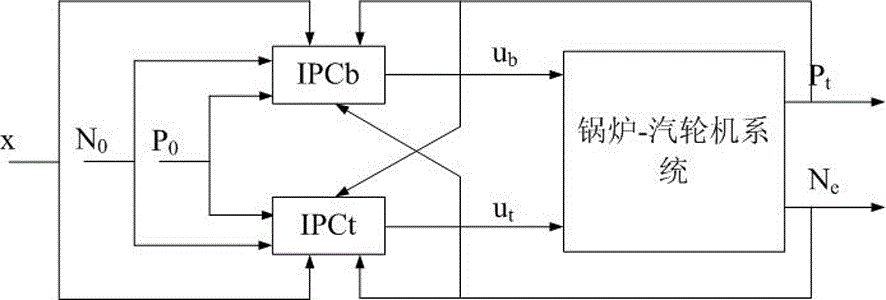

[0071] The following will combine figure 1 with figure 2 And specific embodiments further illustrate the present invention in detail.

[0072] Such as figure 1 with figure 2 As shown, this embodiment relates to a predictive control method of a power plant boiler steam turbine coordinated control system based on intelligent calculation for predictive control law learning. The specific steps are as follows:

[0073] Step 1. Determine the sampling interval T for predictive control s ;

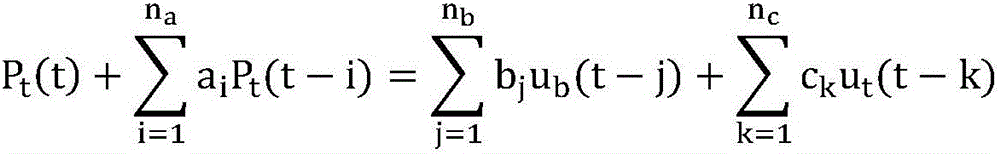

[0074] Step 2. Obtain the local model G described by the input-output differential equation of the boiler steam turbine system under M typical load conditions through the unit characteristic test m ;

[0075] Step 3. Use model predictive control to control all local models G in step 2 m Perform control simulation of square wave signal;

[0076] Step 4. Put all the local models G in step 3 m The control simulation data is used to train the intelligent calculation model to form the intelligent predictiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com