A pop automatic stacking system and method

A technology of automatic stacking and operation methods, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as difficulty in ensuring product quality consistency, low efficiency, and poor precision, and achieve strong manufacturability and universal platform High performance, strong scalability, and the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

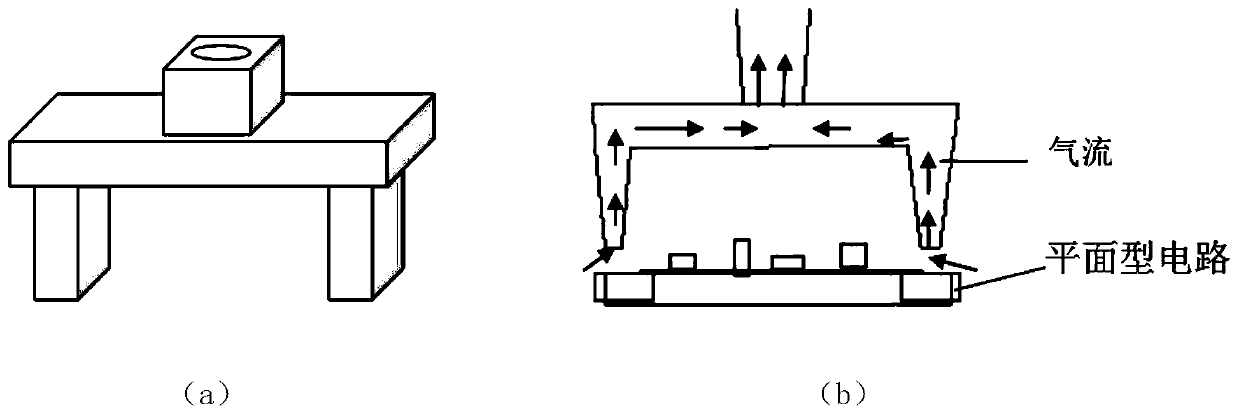

[0086] 3D stack assembly of completed assembled planar substrate circuits

[0087] Various components are assembled on the planar substrate circuit (such as Figure 20 and Figure 21 shown), in order to prevent component damage on the planar circuit assembly, stack mounting cannot be performed directly. When mounting interlayer spacers, suction can be applied simultaneously at two or more point positions of board-type components by using dual / multi-head nozzles. Paste epoxy adhesive film or apply quick-curing glue on the bonding position on the interlayer backing plate through the dispensing system, which can be stacked through the interlayer frame (such as Figure 17 , Figure 18 and Figure 19 shown). The inter-layers are pre-fixed by epoxy adhesive film or fast-curing glue, which can maintain the assembly accuracy between the layers of the stack before further reinforcement.

Embodiment 2

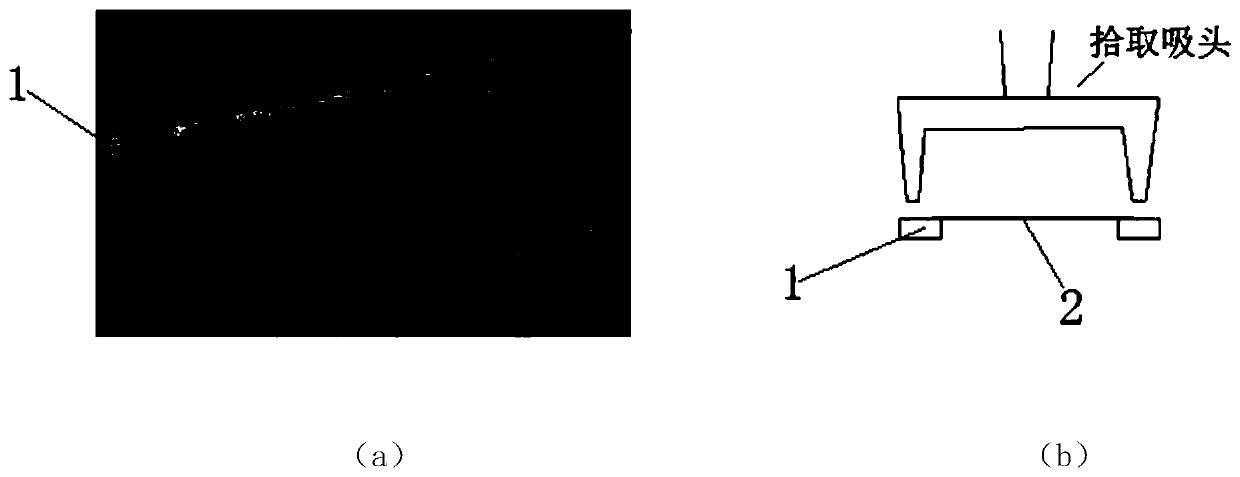

[0089] Mount easily deformable sheet

[0090] The main body of the stack is a plastic-encapsulated chip, but a layer of copper foil 2 with a thickness of only 100 μm and a hollow pattern (such as image 3 shown). Because the copper foil 2 is extremely thin, it is easy to curl and deform, causing it to be unrecognizable by normal camera equipment, and it is difficult to pick it up with a single suction head. By attaching the copper foil 2 on the interlayer spacer, you can rely on the reinforcement function of the interlayer spacer and ensure that it can use double suction heads to achieve normal automatic pick-and-place (such as image 3 and Figure 4 shown).

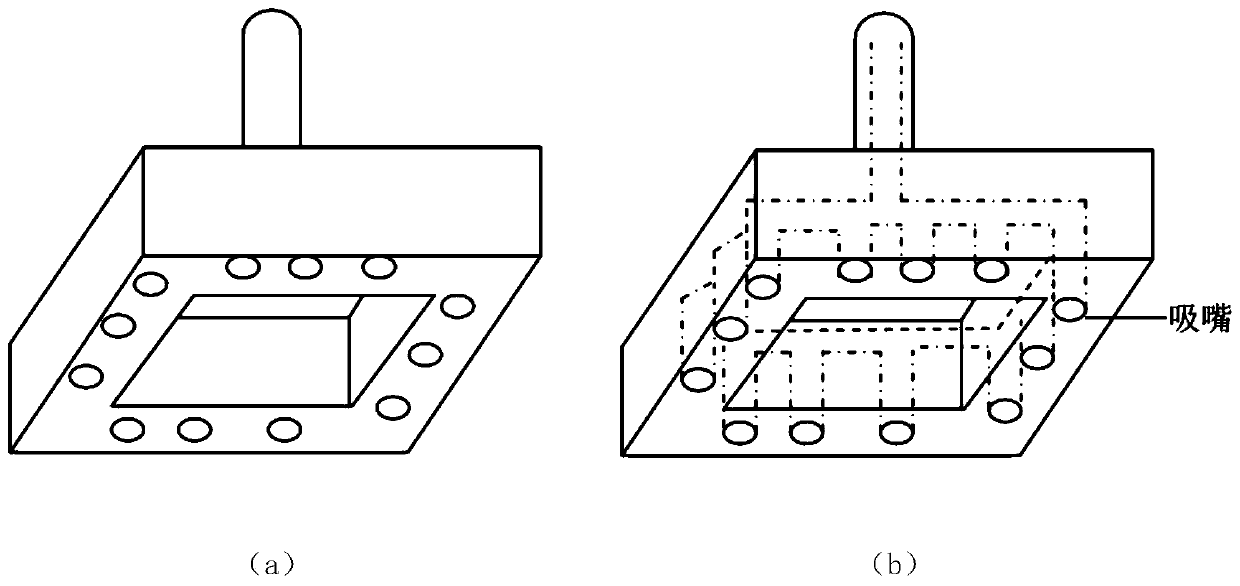

[0091] see Figure 12 , Figure 13 and Figure 14 As shown, the structure of the interlayer cushion frame 1 can adopt the shape of "concave", "back", etc., and the thickness needs to be controlled. If the planned single-layer height is H, and the thickness of the substrate is a, the interlayer bonding material (adh...

Embodiment 3

[0104] Stacking monolithic components is performed in the following steps

[0105] 1) Use the image recognition software to cooperate with the camera system to identify the positioning points / positioning graphics on the single-chip components (see Figure 6 , Figure 10 , Figure 11 );

[0106] 2) The program manipulates the pick-up head for single-chip components, picks up the first layer of single-chip components and places them on the stacked mold;

[0107] 3) Identify and pick up the epoxy film for interlayer bonding, and place it at the designated bonding position of the first layer of monolithic components;

[0108] 4) Identify and pick up the second layer of monolithic components, through the identification system, confirm the positioning point that the upper and lower layers need to be aligned, then move the second layer of monolithic components to the specified position, and lower the pick-up head to make the second layer The component is pressed on the epoxy film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com