Positive electrode active material for lithium secondary battery, preparation method thereof, and lithium secondary battery

A positive electrode active material, lithium secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of life characteristics decline, lithium secondary battery life characteristics, poor thermal stability and reliability, etc., and achieve expansion characteristics Improvement, high temperature and room temperature life characteristics improvement, thermal stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

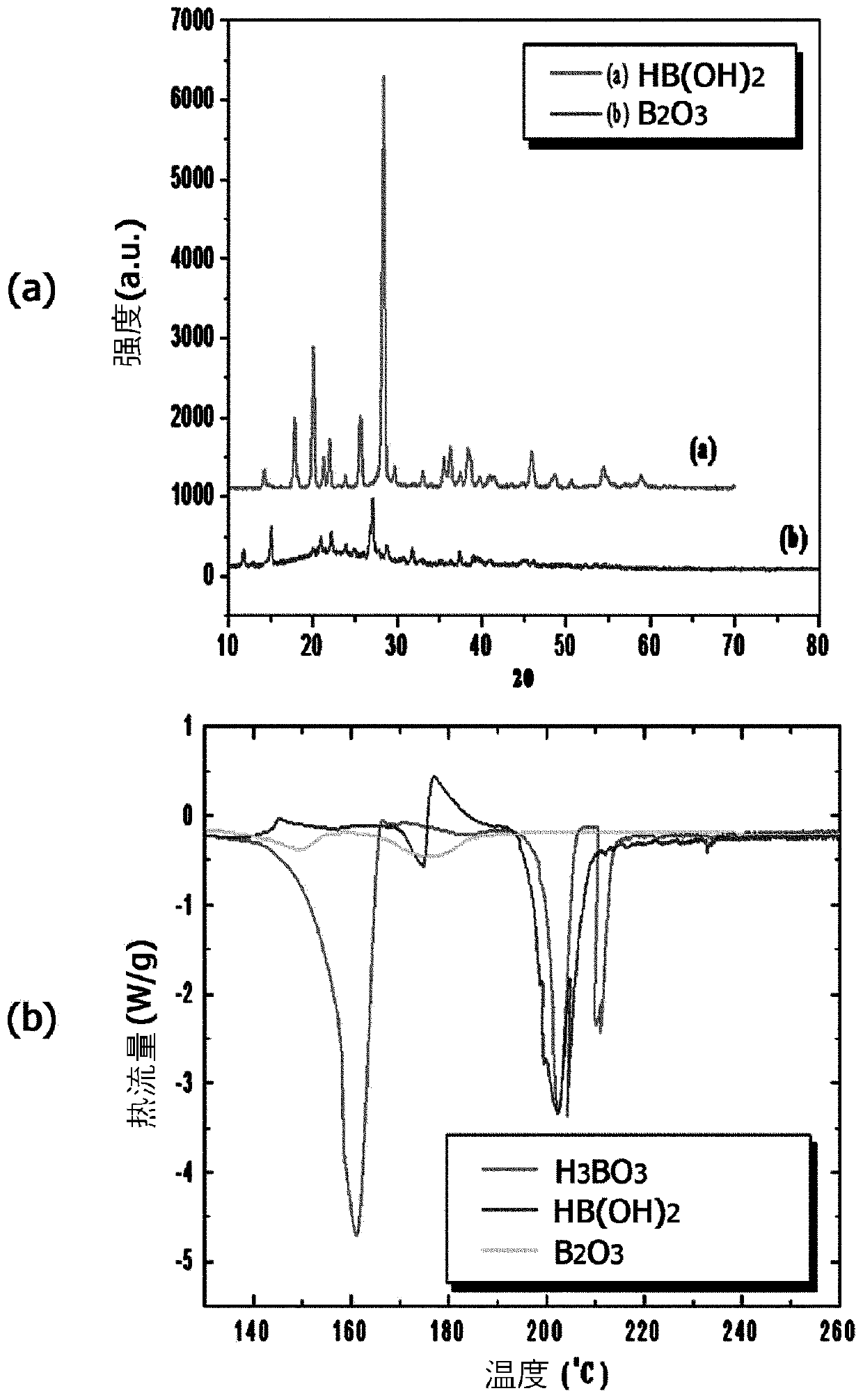

[0061] Moreover, the present invention provides a method for preparing a positive electrode active material for a lithium secondary battery. The method for preparing a positive electrode active material for a lithium secondary battery includes: step a, preparing a lithium-containing compound; step b, preparing a compound selected from Al(OH) 3 solution, a surface treatment solution of two or more solutions in the group consisting of a B-containing compound solution and a Si-containing compound solution; and step c, adding the lithium-containing compound prepared in the above step a to the lithium-containing compound prepared in the above step b After the surface treatment solution is mixed and dried.

[0062] First, in order to prepare a positive electrode active material for a lithium secondary battery, a lithium-containing compound is prepared (step a). The above-mentioned lithium-containing compound has been explained as above.

[0063] Next, in order to prepare a positive...

Embodiment 1

[0078] Under the condition of Li / Me(=Ni+Co+Mn)=1.03~1.05, mix Ni 0.5 co 0.2 mn 0.3 (OH) 2 Precursor (manufacturer: Bangpu) and Li 2 CO 3 (Manufacturer: Lockwood) After that, Li x Ni 0.5 co 0.2 mn 0.3 o 2 . When using a winnowing machine to crush Li x Ni 0.5 co 0.2 mn 0.3 o 2 Thereafter, lithium-containing compound L-1 was prepared by filtering (sieve) through 400 mesh.

[0079] In the separate preparation of Al(OH) 3 Aqueous solution (manufacturer: Snow Chemicals, China) (Al(OH) 3 Concentration (w / w) = 1000ppm), B 2 o 3 Aqueous solution (manufacturer: pure chemical) (B 2 o 3 Concentration (w / w) = 300ppm) and n-SiO 2 Aqueous solution (manufacturer: Aladdin) (n-SiO 2 After concentration (w / w) = 500 ppm), the above-mentioned ingredients were mixed in the same weight ratio to prepare a surface treatment solution S-1.

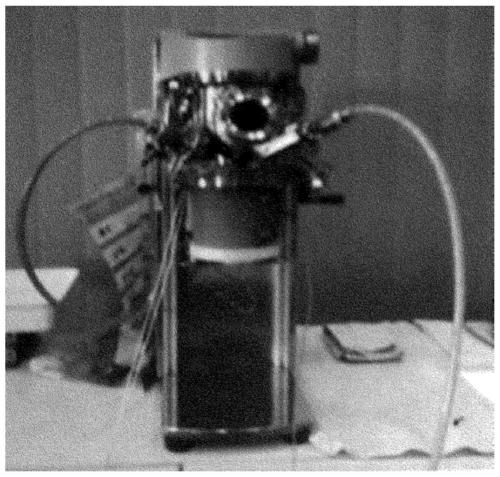

[0080] After that, use figure 1 The shown device slowly adds the lithium-containing compound L-1 to the surface treatment solution S-1 and s...

Embodiment 2

[0083] In the separate preparation of Al(OH) 3 Aqueous solution (manufacturer: Snow Chemicals, China) (Al(OH) 3 Concentration (w / w) = 1000ppm), B 2 o 3 Aqueous solution (manufacturer: pure chemical) (B 2 o 3 Concentration (w / w) = 500ppm) and n-SiO 2 Aqueous solution (manufacturer: Aladdin) (n-SiO 2 After concentration (w / w) = 300 ppm), the above-mentioned ingredients were mixed in the same weight ratio to prepare a surface treatment solution S-2.

[0084] Afterwards, using the figure 1 The shown device slowly adds the lithium-containing compound L-1 to the surface treatment solution S-2 and stirs until the weight ratio of the surface treatment solution S-2 and the lithium-containing compound L-1 is 1:2, after the addition is completed , and additional stirring was performed for about 1 hour. Thereafter, mixing and drying were performed at a temperature of 100° C. for 4 to 6 hours. Thereafter, after performing an additional heat treatment at a temperature of 300° C. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com