Insufficient charging cycle system suitable for matching with lead-carbon battery in energy accumulation scene

A scene matching, lead-carbon battery technology, applied in the application field of the undercharge cycle system, can solve the problems of battery water loss, battery positive grid corrosion, battery overcharge and other problems, and achieve the effect of high cost performance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0023] The present invention includes the following equipment:

[0024] One Jinfan equipment: its model is: 12V150Ah;

[0025] 18 lead-carbon batteries: model LLC-300Ah, 6 for each method;

[0026] Test environment: maintain a normal temperature of 25℃;

[0027] The parameters are designed and tested on the Jinfan equipment.

[0028] The technical scheme of the present invention (the depth of discharge is cycled between 80% and 20%) is as follows:

[0029] 1) If the battery C10 capacity is qualified, discharge it at 0.2C10A for 1h, and adjust the maximum state of charge to 80%;

[0030] 2) Discharge at 0.3C10A for 2h;

[0031] 3) Constant voltage 2.32V / limited current 0.3C10A charge until the total charge capacity reaches 102% of the discharge capacity;

[0032] 4) Repeat 2~3 steps 200 times, after the 200 cycles are over, charge at 2.32V / current limit 0.3C10 for 12h;

[0033] 5) C10 capacity detection (the average termination voltage is 1.80V / cell), after discharging, it will be charged at ...

comparative approach 2

[0043] Comparison plan 2: The depth of discharge is cycled between 100% and 40% (current use plan of lead-acid batteries)

[0044] 1) Qualified the battery C10 capacity test;

[0045] 2) Discharge at 0.2C10A for 3h;

[0046] 3) Constant voltage 2.35V / current limit 0.2C10A charging for 6h;

[0047] 4) Repeat 2~3 steps 100 times, and charge for 12h at 2.35V / current limit 0.2C10 after 100 cycles;

[0048] 5) C10 capacity detection (the average termination voltage is 1.80V / cell), after the discharge is completed, it will be charged at 2.35V / current limit 0.15C10A for 16h;

[0049] 7) Repeat steps 1 to 6, when the battery capacity is less than 60% of the rated capacity at 10h rate, record the number of cycles, and end the test when it is confirmed that it is still less than 60%. The last 100 cycles are not included in the number of large cycles .

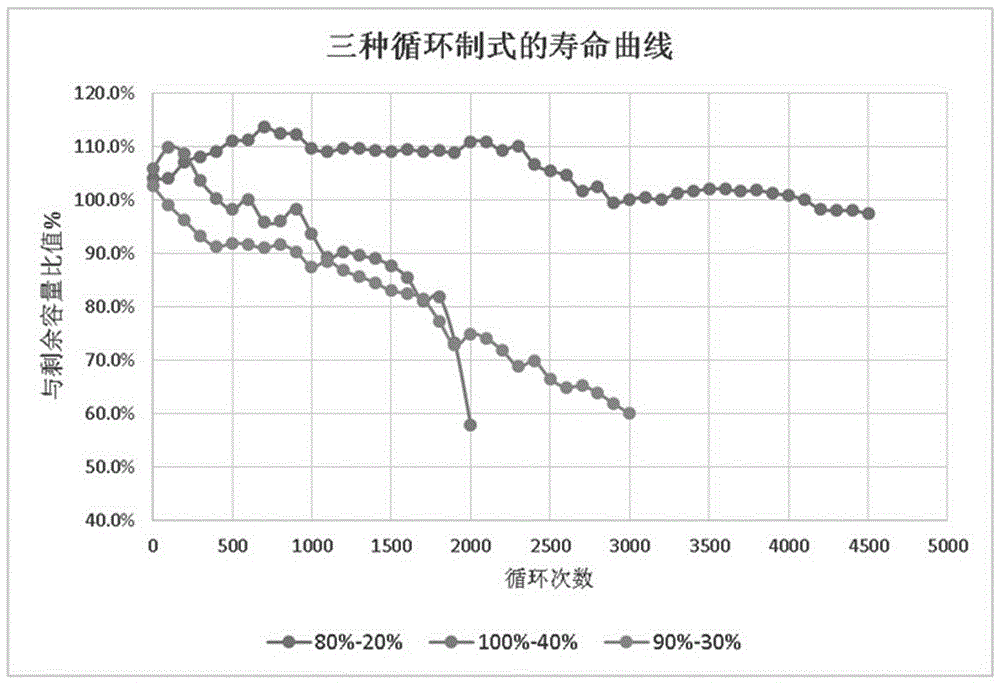

[0050] Such as figure 1 From the above test results, it can be shown that the cycle system of the present invention can increase the number of 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com