Tea processing method

A processing method and technology of tea, which is applied in the field of tea processing, can solve the problems of cumbersome preparation process and long cycle, and achieve the effects of simple process flow, high aroma and huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

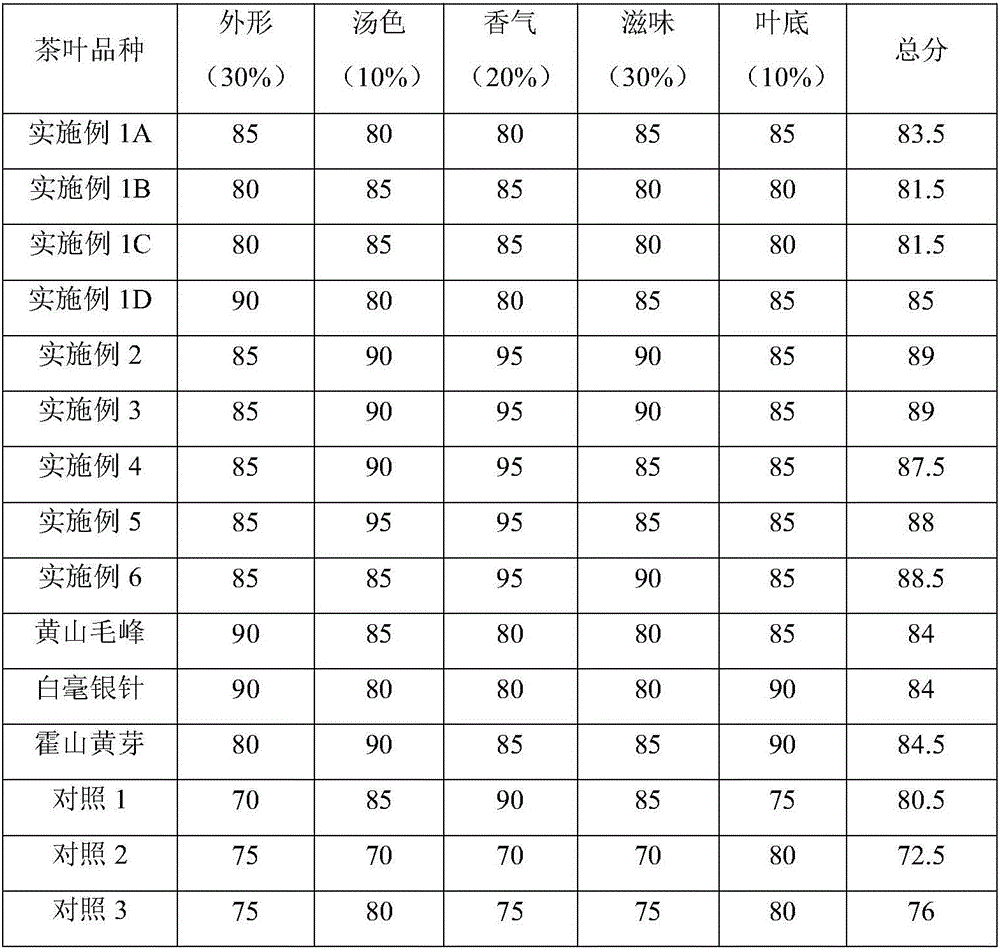

Examples

Embodiment 1

[0030] Follow the steps below for tea processing:

[0031] (1) Picking of fresh leaves: The picking period of fresh tea leaves is June 2016; the location is the tea garden of Agricultural Science and Technology Park of Anhui Agricultural University, Hefei City, Anhui Province; the varieties are Longjing 43, Nongkangzao, Shuchazao, and Anjibaicha, For convenience, the four teas are marked as A, B, C, and D; the picking standard is one bud with three leaves and four leaves.

[0032] (2) Withering: Natural withering is adopted, and the fresh leaves are quickly and thinly spread in a water sieve, the room temperature is controlled at 25° C., and the relative humidity is controlled at 73%. Wither 24 hours for the first time and sieve, 48 hours for the second time and 60 hours for the next step of drying.

[0033] (3) Drying: Put the withered leaves into a rotary dryer with a temperature of 115° C., an initial drying time of 15 minutes, and an initial drying moisture content of 30%...

Embodiment 2

[0040] Follow the steps below for tea processing:

[0041] (1) Picking of fresh leaves: The picking period of fresh tea leaves is June 2016; the location is the tea garden of Agricultural Science and Technology Park of Anhui Agricultural University, Hefei City, Anhui Province; the variety is Fuding Dabai tea variety; the picking standard is one bud with three and four leaves .

[0042] (2) Withering: Natural withering is adopted, and the fresh leaves are quickly and thinly spread in a water sieve, the room temperature is controlled at 20° C., and the relative humidity is controlled at 60%. Wither 18 hours for the first time and sieve, 32 hours for the second time and 54 hours for the next step of drying.

[0043] (3) Drying: Put the withered leaves into a rotary dryer with a temperature of 110° C., an initial drying time of 30 minutes, and an initial drying moisture content of 20%.

[0044] Rebaking: The temperature is controlled at about 90°C. Bake until the water content ...

Embodiment 3

[0050] Follow the steps below for tea processing:

[0051] (1) Picking of fresh leaves: The picking period of fresh tea leaves is June 2016; the location is the tea garden of Agricultural Science and Technology Park of Anhui Agricultural University, Hefei City, Anhui Province; the varieties are Zhenghe Dabai tea varieties; the picking standard is one bud with three and four leaves.

[0052] (2) Withering: Natural withering is adopted, and the fresh leaves are quickly and thinly spread in a water sieve, the room temperature is controlled at 20° C., and the relative humidity is controlled at 60%. Wither 18 hours for the first time and sieve, 32 hours for the second time and 54 hours for the next step of drying.

[0053] (3) Drying: put the withered leaves into a rotary dryer, the temperature of the dryer is 130°C, the initial drying time is 15 minutes, and the initial drying moisture content is 20%;

[0054] Rebaking: The temperature is controlled at about 90°C. Bake until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com