Metoclopramide oral film and preparation method thereof

A technology of metoclopramide and oral film, which is applied in the field of metoclopramide oral film and its preparation, can solve the problems of pain in injections, difficulty in self-administration, poor compliance, etc., and achieve brittle High fragmentation, avoid first-pass effect, and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

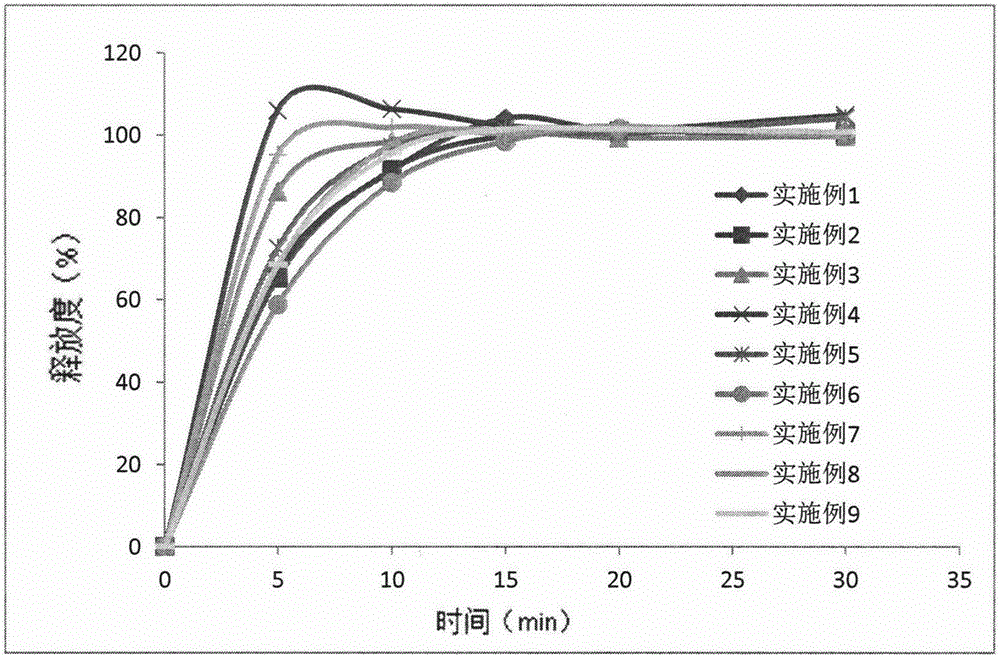

Examples

Embodiment 1

[0030] Weigh 0.80g of PVA05-88, add 6ml of pure water, swell for 30min, heat in a water bath at 85°C to form a clear PVA solution; weigh 0.40g of CMC-Na, disperse it on the surface of 6ml of pure water, wait for it to sink and dissolve naturally, and let it stand overnight to obtain a viscous CMC-Na solution; mix the two solutions to obtain a composite film-making glue. Weigh 0.10g of ALG-Na dissolved in 5ml of pure water to obtain a viscous solution, and add it into the film-making glue. Weigh 0.20g of metoclopramide and add 3ml of pure water to dissolve, add 0.10g of aspartame to the solution, stir and mix, pour into the compound film-making glue, then add 0.20ml of glycerin, stir, ultrasonic, and let stand Defoaming. That is, the drug-containing mixed glue is obtained.

[0031] Sprinkle a small amount of release agent talcum powder on the board in advance, and evenly cover the whole board. Pour an appropriate amount of film slurry on the glass plate, adjust the height of...

Embodiment 2

[0033] Weigh 0.66g of PVA05-88, add 6ml of pure water, swell for 30min, heat in a water bath at 85°C to form a clear PVA solution; weigh 0.33g of CMC-Na, disperse it on the surface of 6ml of pure water, wait for it to sink and dissolve naturally, and let it stand overnight to obtain a viscous CMC-Na solution; mix the two solutions to obtain a composite film-making glue. Weigh 0.10g of ALG-Na dissolved in 5ml of pure water to obtain a viscous solution, and add it into the film-making glue. Weigh 0.20g of metoclopramide and add 3ml of pure water to dissolve it, add 0.10g of aspartame to the solution, stir and mix, pour into the compound film-making glue, then add 0.50ml of glycerin, stir, ultrasonic, and let it stand Defoaming. That is, the drug-containing mixed glue is obtained.

[0034] Sprinkle a small amount of release agent talcum powder on the board in advance, and evenly cover the whole board. Pour an appropriate amount of film slurry on the glass plate, adjust the hei...

Embodiment 3

[0036] Weigh 0.53g of PVA05-88, add 6ml of pure water, swell for 30min, heat in a water bath at 85°C to form a clear PVA solution; weigh 0.27g of CMC-Na, disperse it on the surface of 6ml of pure water, wait for it to sink and dissolve naturally, and let it stand overnight to obtain a viscous CMC-Na solution; mix the two solutions to obtain a composite film-making glue. Weigh 0.10g of ALG-Na dissolved in 5ml of pure water to obtain a viscous solution, and add it into the film-making glue. Weigh 0.20g of metoclopramide and add 3ml of pure water to dissolve, add 0.10g of aspartame to the solution, stir and mix, pour into the composite film-making glue, then add 1.00ml of glycerin, stir, ultrasonic, and let stand Defoaming. That is, the drug-containing mixed glue is obtained.

[0037] Sprinkle a small amount of release agent talcum powder on the board in advance, and evenly cover the whole board. Pour an appropriate amount of film slurry on the glass plate, adjust the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com