50 kilogram-grade flux-cored wire for relieving stress after welding

A technology of stress relief and flux-cored welding wire, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of reducing the yield strength and tensile strength of the weld, the decline of low-temperature impact performance, and the reduction of thermal cracking resistance and other problems, to achieve the effect of improving thermal cracking resistance, excellent cracking resistance, and improving cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

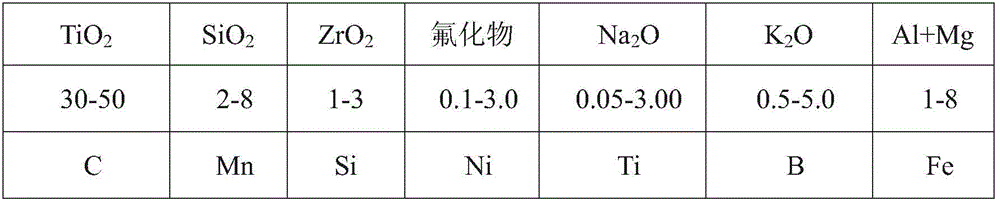

[0110] Adopt the general manufacturing process in the welding wire production industry, make the steel strip (i.e. the outer skin) according to the steel strip components in Table 1-1, prepare according to the welding flux formula in Table 1-2, and wrap the flux in the steel strip (overlap ):

[0111] Table 1-1: Steel strip composition (%)

[0112] C Si mn Al P S Fe 0.022 0.015 0.14 0.022 0.006 0.005 margin

[0113] Table 1-2: Soldering Flux Formulation (%)

[0114] TiO 2

SiO 2

ZrO 2

Fluoride Na 2 o

K 2 o

Al+Mg 37.8 3.6 2.5 1.5 0.74 3.2 2.8 C mn Si Ni Ti B Fe 0.10 16.3 1.6 2.5 1.5 0.06 25.80

[0115] The chemical composition of the deposited metal is shown in Table 1-3, and the mechanical properties of the deposited metal and the diffusible hydrogen content of the deposited metal (mercury method) in the welded state and the stress-relieved annealed state (620°C×4h)...

Embodiment 2

[0121] Adopt the same welding wire manufacturing method as in Example 1, and prepare according to the steel strip components in Table 2-1 and the flux formulation in Table 2-2:

[0122] Table 2-1: Steel strip composition (%)

[0123] C Si mn Al P S Fe 0.027 0.018 0.15 0.030 0.008 0.007 margin

[0124] Table 2-2: Soldering Flux Formulation (%)

[0125]

[0126]

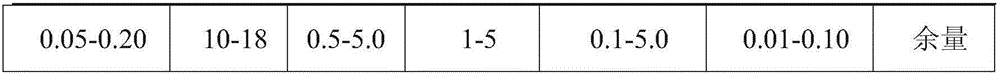

[0127] The chemical composition of the deposited metal is shown in 2-3. The mechanical properties of the deposited metal and the diffusible hydrogen content of the deposited metal (mercury method) in the welded state and the stress-relieved annealed state (620°C×4h) are shown in Table 2-4:

[0128] Table 2-3: Chemical composition of deposited metal (%)

[0129] C mn Si P S Al Ni Ti B 0.038 1.18 0.25 0.007 0.007 0.009 0.45 0.052 0.0027

[0130] Table 2-4: Mechanical properties and diffusible hydrogen of deposited metal

[0131]

Embodiment 3

[0133] Adopt the same welding wire manufacturing method as in Example 1, and prepare according to the steel strip components in Table 3-1 and the flux formulation in Table 3-2:

[0134] Table 3-1: Steel strip composition (%)

[0135]

[0136]

[0137] Table 3-2: Soldering Flux Formulation (%)

[0138] TiO 2

SiO 2

ZrO 2

Fluoride Na 2 o

K 2 o

Al+Mg 42.3 5.4 2.1 1.7 0.56 2.7 3.8 C mn Si Ni Ti B Fe 0.11 15.4 2.4 2.9 1.8 0.06 18.77

[0139] The chemical composition of the deposited metal is shown in 3-3. The mechanical properties of the deposited metal and the diffusible hydrogen content of the deposited metal (mercury method) in the welded state and the stress-relieved annealed state (620°C×4h) are shown in Table 3-4:

[0140] Table 3-3: Chemical composition of deposited metal (%)

[0141] C mn Si P S Al Ni Ti B 0.041 1.23 0.28 0.007 0.006 0.011 0.47 0.054 0.0025...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com