Narrow gap welding line grinding and repairing machine

A grinding machine, narrow gap technology, applied in the direction of grinding frames, grinding machine parts, grinding machines, etc. The effect of covering the application range, simple repair and construction, and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

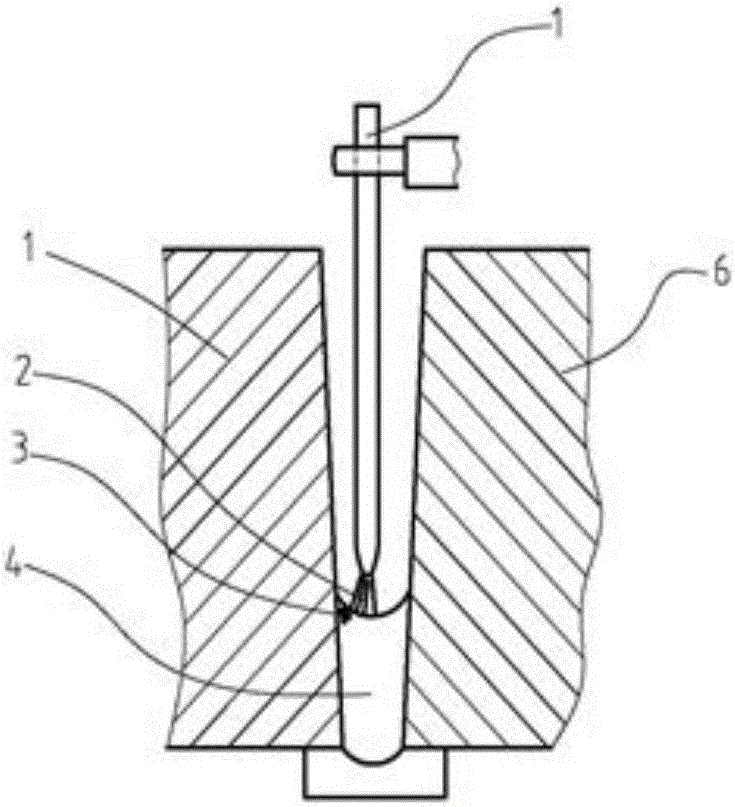

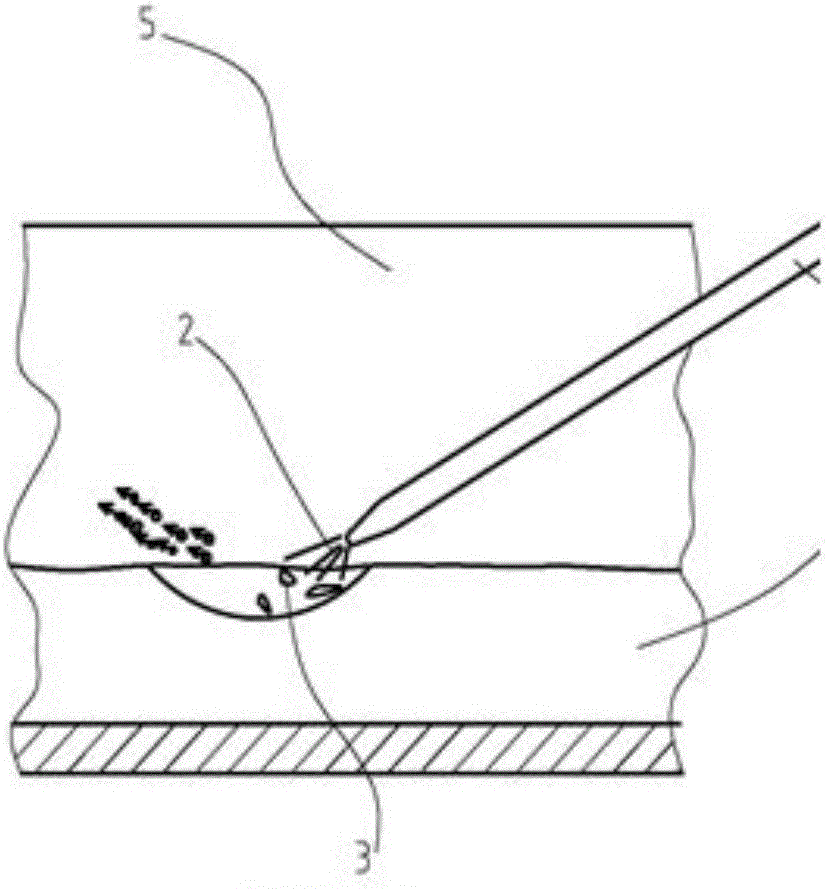

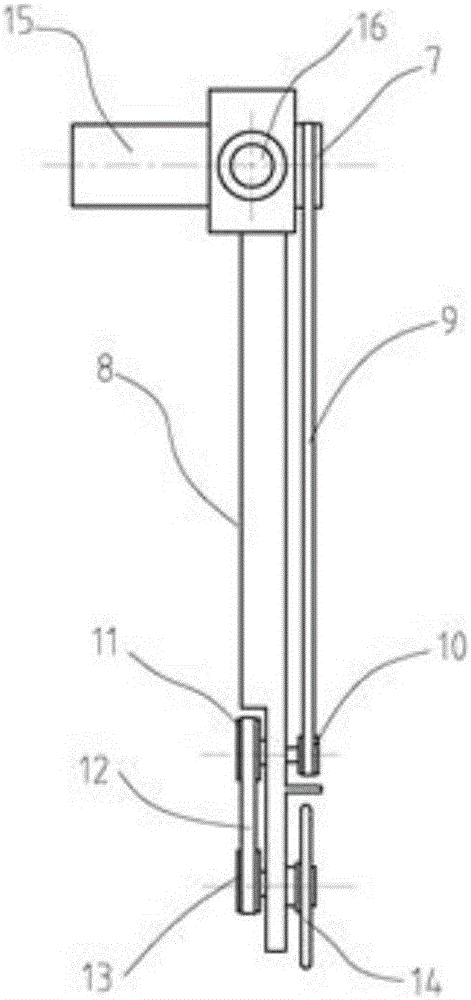

[0019] This embodiment is a basic embodiment of the present invention. Such as figure 2 , 3 , shown in 4, a kind of narrow-gap welding seam grinding machine, by motor 15, handle 16, driving pulley 7, grinder base 8, transmission pulley 9, driven pulley 10, shift pulley 11, working belt 12 , Working pulley 13, emery wheel sheet 14 and belt switch handle 17 form. Motor 15 is installed on the upper end of grinding machine base 8, and driving pulley 7 is installed at the output shaft end of motor 15; Position pulley 11 is coaxial with driven pulley 10; coaxial working pulley 13 and grinding wheel piece 14 are installed at the bottom of grinding machine base 8, between driving pulley 7 and driven pulley 10, shifting pulley 11 and working pulley Between 13, transmit torque by transmission belt 9 and work belt 12 respectively; The left and right sides of motor 15 output seats are respectively equipped with the control handle 16 without motor switch and the control handle 17 of ba...

Embodiment 2

[0025] Such as Figure 5 As shown, the grinding wheel sheet 14 is coaxially installed on the driven pulley 10, the shift pulley 12 and the working pulley 13 are removed, and the rest of the structure is the same as that of embodiment 1. This kind of grinding machine is mainly used for cleaning splashes and digging out defects on both side wall grooves and adjacent areas in deep and narrow grooves. Grinding wheel sheet 14 selects the specification of diameter φ 125mm thickness 3mm for use. The specific embodiments described herein are merely illustrative of the spirit of the invention. Those skilled in the art to which the present invention belongs can make various modifications or supplements to the described specific embodiments or adopt similar methods to replace them, but they will not deviate from the spirit of the present invention or go beyond the definition of the appended claims range.

[0026] Although this article uses 1-carbon rod (铇 bar), 2-arc, 3-welding defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com