Aluminum wire coloring agent composition and coloring method

A colorant and composition technology, which is applied in the field of metal surface treatment, can solve the problems of high strength of iron wire, cannot be realized, and destroy the growth of tree trunks, and achieve the effects of simple preparation process, easy realization and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

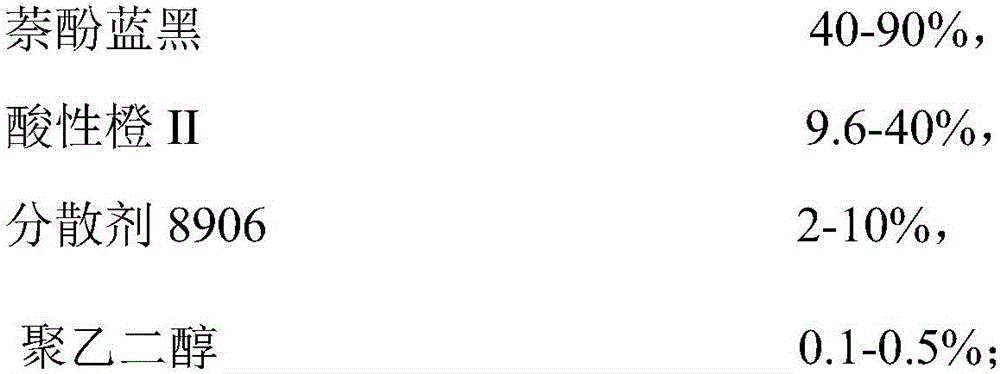

Image

Examples

Embodiment 1

[0035] The process of tinting raw billet aluminum wire with a black bronze tone includes:

[0036] a) Degreasing: removing grease from the surface of the raw aluminum wire;

[0037] b) Water washing: wash with hot water;

[0038] c) Polishing: removing ash and shining light on the raw billet aluminum wire;

[0039] d) washing: repeat step b);

[0040] e) Oxidation: Put the original billet aluminum wire into an anodic oxidation solution for anodic oxidation treatment, prepare the anodic oxidation solution according to the following ingredients and proportions: first pour about 2 / 3 volume of deionized water, sulfuric acid ( h 2 SO 4 ) 200g / L was added to stir and cool, and during operation, an external aluminum plate was added to connect the negative pole of the power supply and put it into the anodic oxidation solution, and the raw aluminum wire was connected to the positive pole of the power supply and put into the anodic oxidation solution; operating electrolysis voltage:...

Embodiment 2

[0048] The process of tinting raw billet aluminum wire with a black bronze tone includes:

[0049] a) Degreasing: removing grease from the surface of the raw aluminum wire;

[0050] b) Water washing: wash with hot water;

[0051] c) Polishing: removing ash and shining light on the raw billet aluminum wire;

[0052] d) washing: repeat step b);

[0053] e) Oxidation: Put the original billet aluminum wire into an anodic oxidation solution for anodic oxidation treatment, prepare the anodic oxidation solution according to the following ingredients and proportions: first pour about 2 / 3 volume of deionized water, sulfuric acid ( h 2 SO 4 ) 200g / L was added to stir and cool, and during operation, an external aluminum plate was added to connect the negative pole of the power supply and put it into the anodic oxidation solution, and the raw aluminum wire was connected to the positive pole of the power supply and put into the anodic oxidation solution; operating electrolysis voltage:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com