Continuous open-width washing structure

A technology of open-width water washing and water washing tank, which is used in textile and papermaking, liquid/gas/vapor textile processing, liquid/gas/vapor processing of indefinite-length textile materials, etc. Uniform, easy to scratch the fabric and other issues, to meet the requirements of the washing process, save production time, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

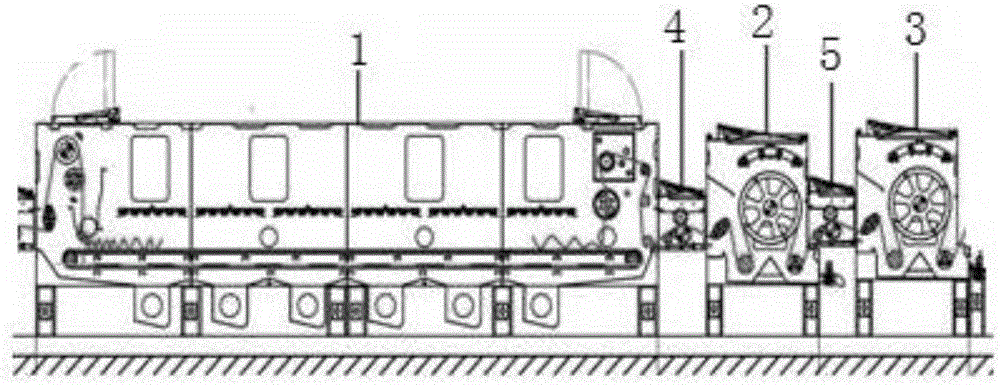

[0012] Such as figure 1 The shown continuous open-width washing cleaning structure is composed of a washing water tank 1, a first washing water single drum box 2 and a second washing water single drum box 3, wherein the washing water tank 1, the first washing water The first small rolling car 4 is set between the single drum boxes 2, the second small rolling car 5 is set between the first washing water single drum box 2 and the second washing water single drum box 3; the washing water tank 1 is mesh belt soaping Box; the first washing water single drum box 2 and the second washing water single drum box 3 are respectively two-roll rolling car washing tanks.

[0013] Specifically, the fabric is stacked in the washing water tank through the washing water tank 1, and the residual additives on the cloth surface are cleaned more efficiently by circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com