Oil well alloy superconducting wax and pressure and temperature measurement device

A temperature measuring device and superconducting technology, which is applied in the direction of measurement, drilling equipment, borehole/well components, etc., can solve the problems of complex structure of special cables, mutual signal interference, and low measurement accuracy, so as to improve measurement accuracy and improve The effect of high power and temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

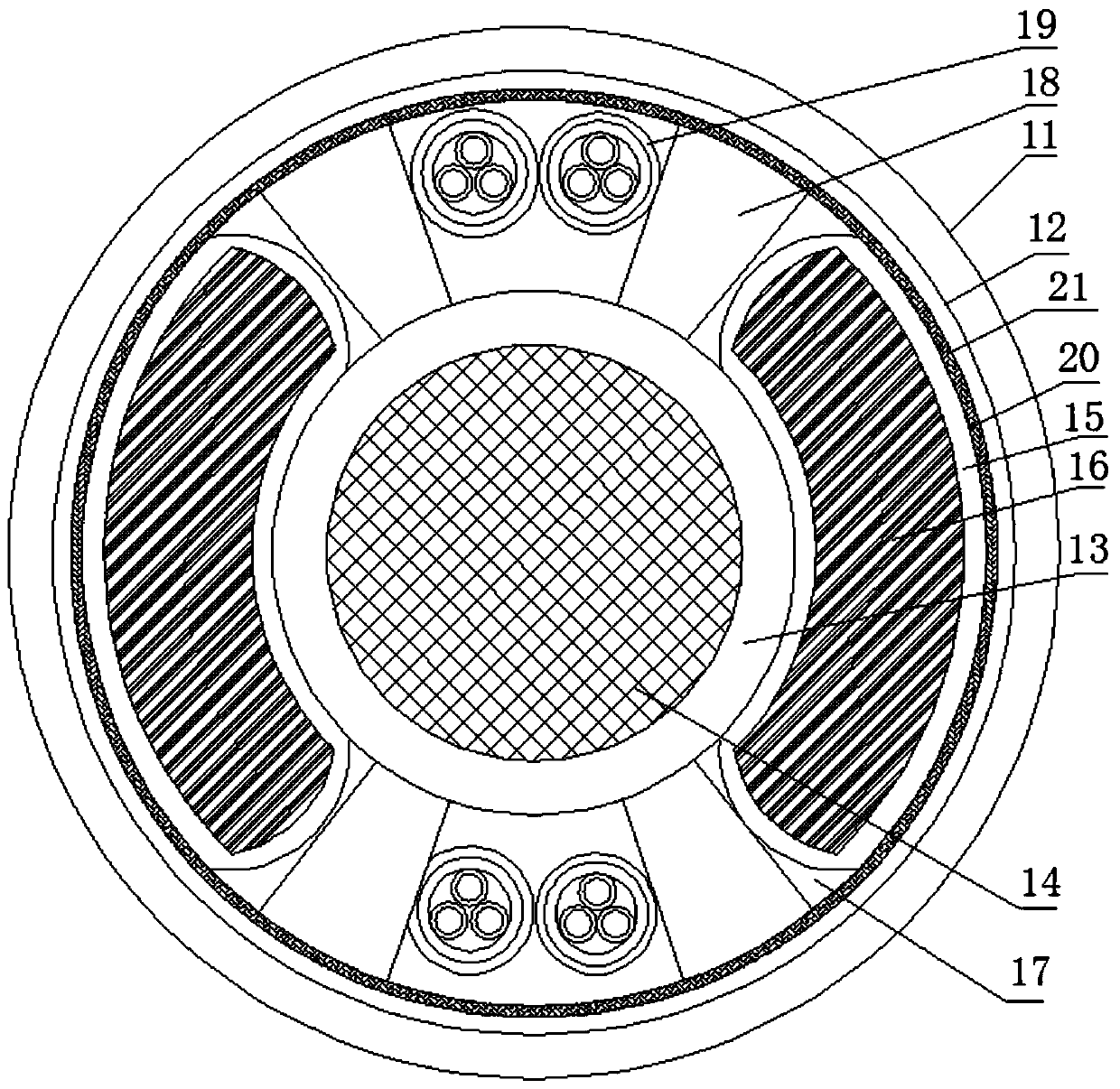

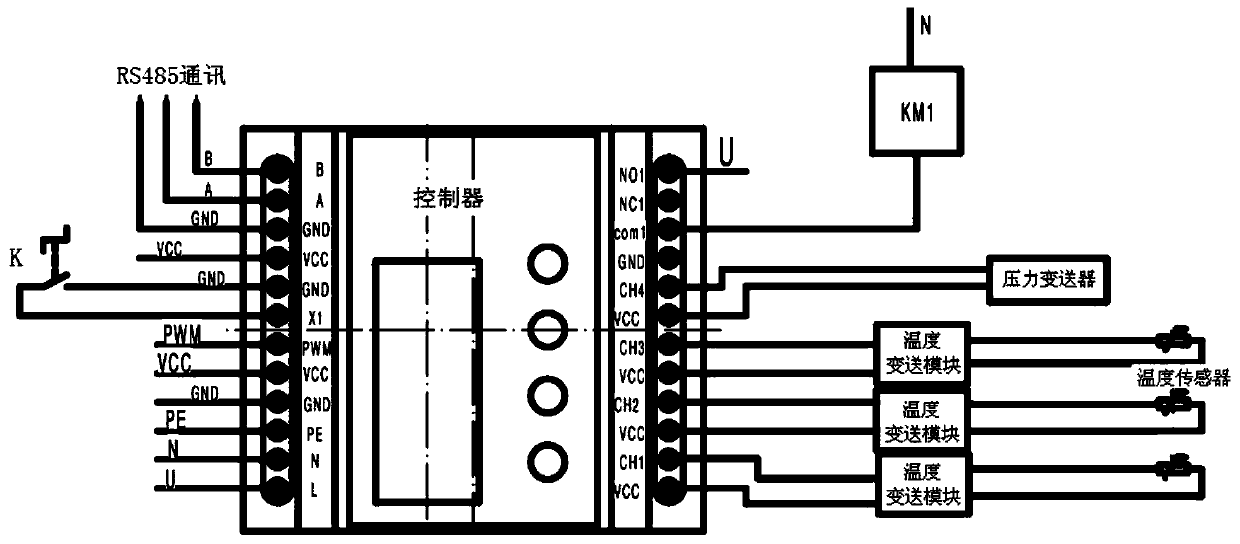

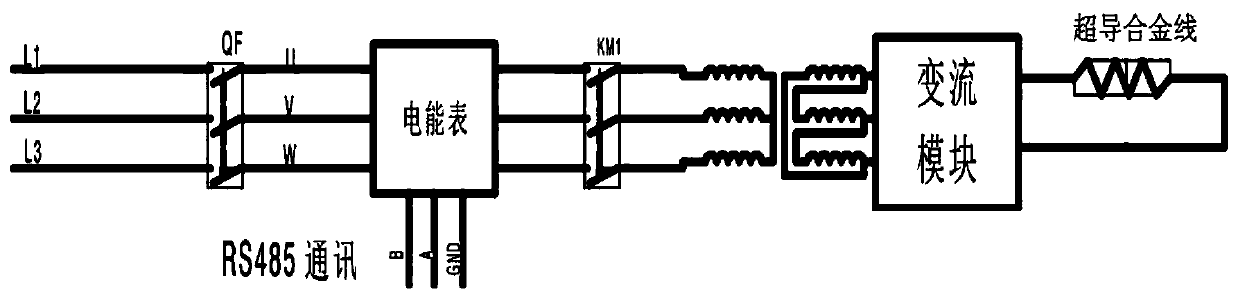

[0029] Such as Figure 1~Figure 3 Shown: an oil well alloy superconducting wax and a pressure and temperature measurement device, including a cable body and a control system penetrating into a hollow sucker rod; inside the cable body are distributed temperature sensors for measuring different depths in the well. There is also a pressure transmitter at the bottom, and the temperature sensor and the pressure transmitter are electrically connected to the control system on the well through the wires running through the cable body; the control system includes a controller, and the input end of the controller is connected to the temperature sensor and the pressure transmitter. Transmitter; the cable body is also provided with a superconducting alloy wire 16, and is connected to an intermediate frequency alternating current.

[0030] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com