Characterization method for biogas residue aerobic composting fermentation maturity

A technology for aerobic composting and composting maturity, which is applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of time-consuming and laborious environment, pollution, inability to apply detection methods, etc., and achieve convenient environmental pollution and good application. Prospects, test methods, fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

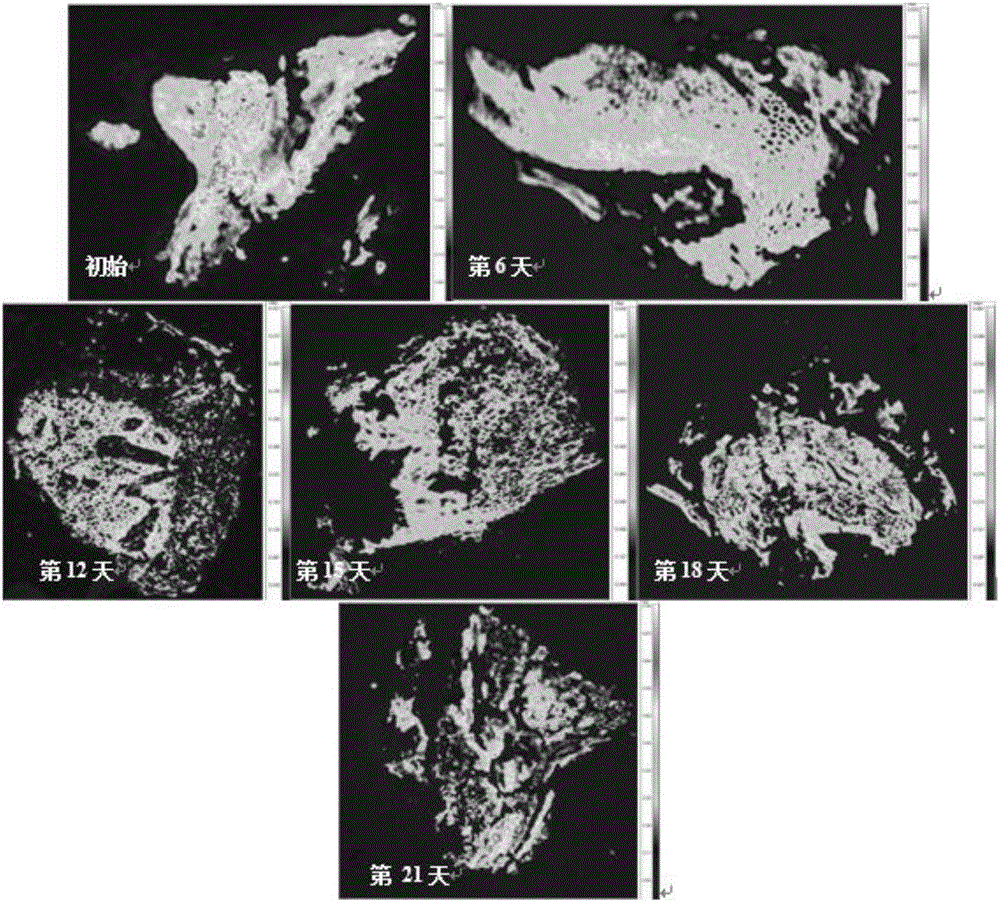

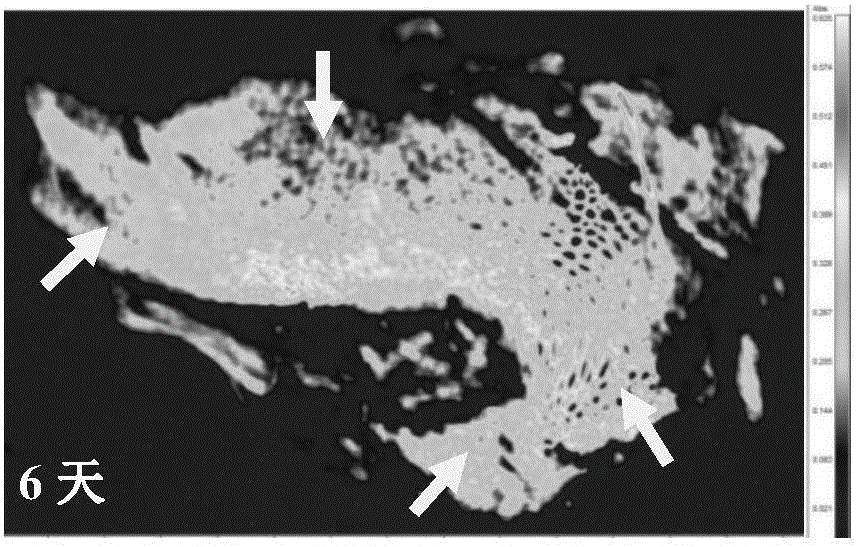

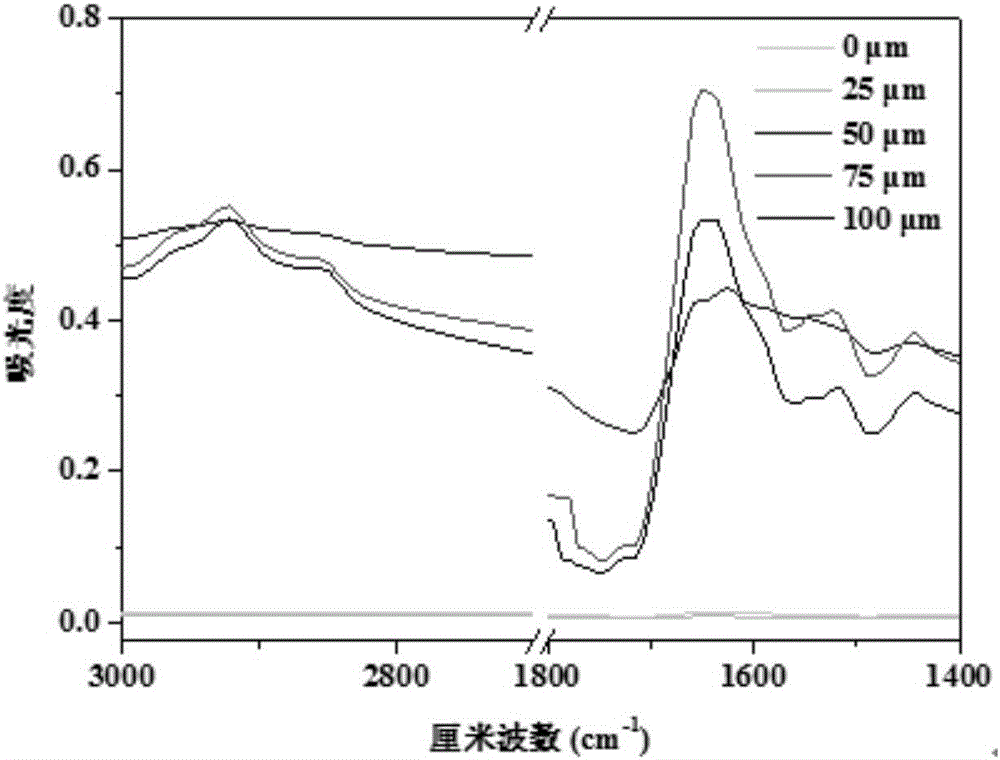

[0046] 1. Composting test

[0047] 1. Compost raw materials

[0048] Chicken manure biogas residue was taken from a biogas station in Daxing District, Beijing. The anaerobic reactor was an upflow solid anaerobic reactor. The obtained chicken manure biogas residue was the solid part of solid-liquid separation after mesophilic anaerobic fermentation for 18 days; From Shandong, cut short to 3-5cm for later use.

[0049] 2. Process parameters and control scheme

[0050] (1) Evenly mix chicken manure biogas residue and wheat straw at a ratio of 22.5:1, control the moisture content and carbon-nitrogen ratio of the initial mixed material at about 65% and 25 respectively, and the total weight is 47kg; compost raw materials and initial materials are basically physical and chemical The characteristics are listed in Table 1, and Table 1 is the basic physical and chemical characteristics of compost raw materials and initial materials;

[0051] Table 1 Basic physical and chemical proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com