A fiber optic filter device

A technology of optical fiber filtering and optical fiber lines, applied in optics, light guides, optical components, etc., can solve problems such as uneven heating, optical fiber signal attenuation, signal distortion, etc., achieve uniform and effective heating, good heat preservation performance, and actively filter out optical noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

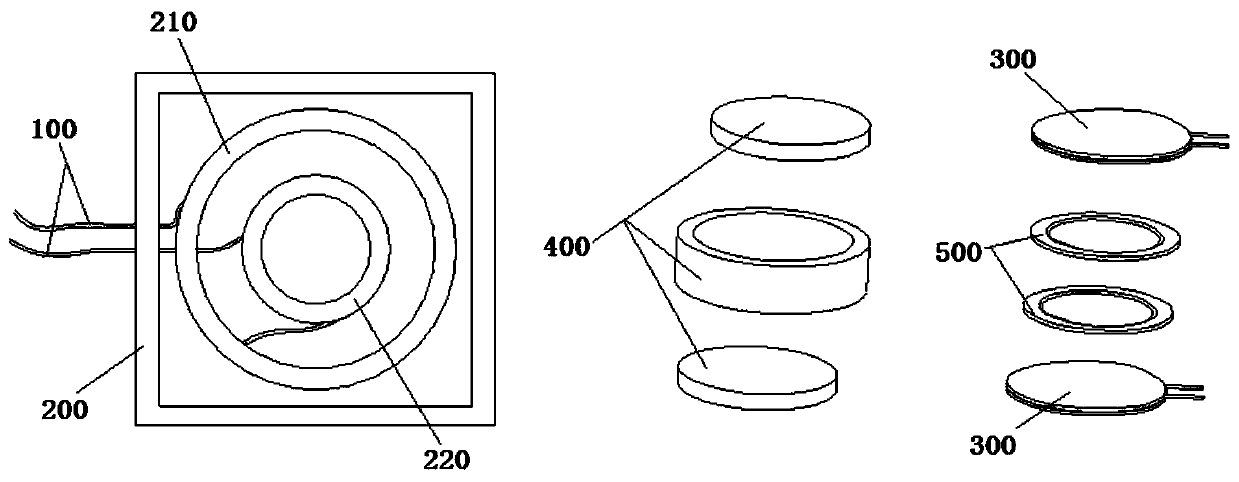

[0027] Such as figure 1 As shown, the present invention provides an optical fiber filtering device, comprising: an optical fiber cable 100, an optical fiber box 200, a heating sheet 300, a heat insulating cotton 400, and a heat-conducting silica gel sheet 500; the outer coiling part 210 and the The inner coiled part 220; the outer coiled part 210 has a storage space for accommodating 100-150 meters of optical fiber in the form of coiling; the optical fiber 100 enters after being wound for 100-150 meters by the outer coiled part The inner coiled part 220; the inner coiled part is wrapped with the heat insulation cotton 400; the inner wall of the heat insulation cotton 400 is attached with the thermal conductive silica gel sheet 500; the heating sheet 300 is laid on the heat insulation Cotton 400 and the heat-conducting silica gel sheet 500; the optical fiber cable 100 is drawn out of the optical fiber box 200 after being wound at the inner coiling part 220, and the coil formed ...

Embodiment 2

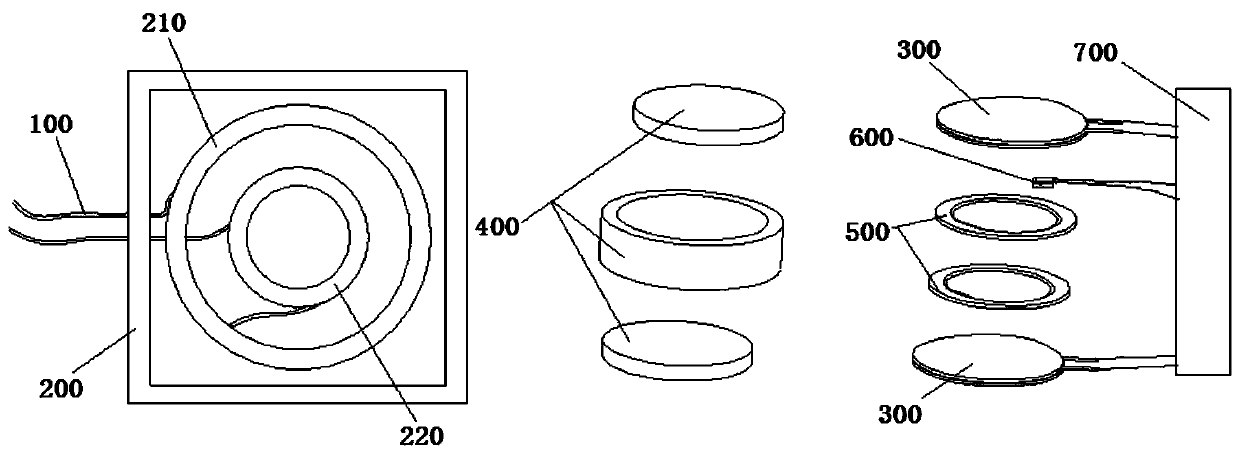

[0036] figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a temperature sensor 600 is also attached to the thermally conductive silica gel sheet 500; a controller 700 is provided on the power supply connected to the heating sheet; the temperature sensor 600 is connected with The controller 700 is connected; when the optical fiber filter device is working, the variation range of the inner coiled part near the working temperature setting value is less than 0.1 degrees Celsius.

[0037] It should be noted that the temperature sensors and controllers used in this embodiment are prior art, so the detailed structures and models of the above temperature sensors and controllers will not be further illustrated and described here.

[0038] Preferably, in a preferred technical solution of this embodiment, the set value of the working temperature is between 24°C and 60°C. The present invention selects the above-mentioned constant temperature interval as the working tem...

Embodiment 3

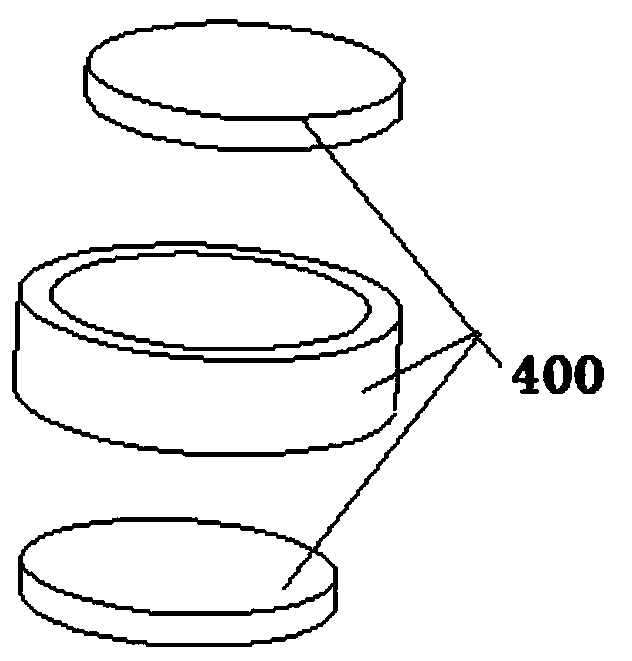

[0041] image 3 As shown, on the basis of the above-mentioned embodiments, the heat insulation cotton of the present invention includes: a heat insulation cylinder made of heat insulation cotton, and two end caps whose shape is adapted to the cross-sectional shape of the inner wall of the heat insulation cylinder ; after the heat insulation cylinder is fastened by the end cover, the inner coil is sealed. The present invention achieves the technical effect of high-efficiency thermal insulation of the inner coiled part by adopting the heat-insulation cotton with the above-mentioned structure.

[0042] Preferably, this embodiment is based on the above embodiments, the thickness of the heat insulation cylinder and the end cap is not less than 10 mm. The present invention can obtain high-quality heat preservation and heat insulation effect by adopting the heat insulation cylinder with the above thickness, and provide strong structural support for creating a constant temperature fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com