Fuel pellet and preparation method thereof

A fuel pellet and fuel technology, which is applied in the field of nuclear reactors, can solve the problems of reduced core uranium loading, shortened cycle length, limited internal flow, etc., so as to improve safety and economy, improve thermal margin, and reduce core Effect of block center temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

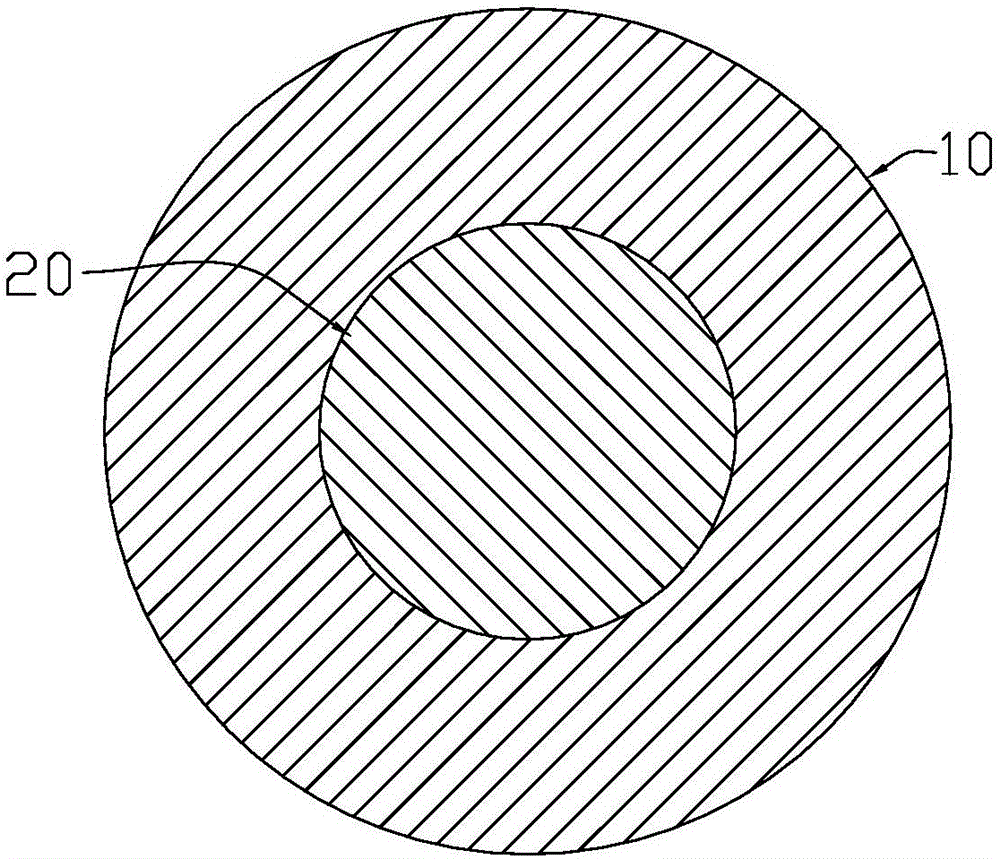

[0053] refer to figure 1 , the preparation method of the fuel pellet of an embodiment of the present invention, comprises the following steps:

[0054] S1. After mixing the fissile material and additives as raw materials, press to form the second fissionable part 20 .

[0055] Wherein, the volume percentage of the additive in the second fissionable part 20 is 5-25%. The additives include one or more of SiC particles, BeO, nanodiamonds, and carbon nanotubes.

[0056]The fissionable material is fissionable material in the form of oxides, carbides or nitrides, or is MOX fuel. Alternatively, the fissile material includes uranium-containing fissile material, further enriched uranium in the form of oxides, carbides or nitrides (such as UO 2 powder).

[0057] Step S1 may further include the following steps:

[0058] S1.1. First macroscopically mix the fissile material powder and additives, then co-grind or micro-mix in a hammer mill, and then use a roll press to press into table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com