Trench capacitor and production method thereof

A technology of trench capacitors and trenches, applied in capacitors, circuits, electrical components, etc., can solve problems such as high precision requirements and difficult industrial production, and achieve low precision requirements, reduce process costs, and simplify production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

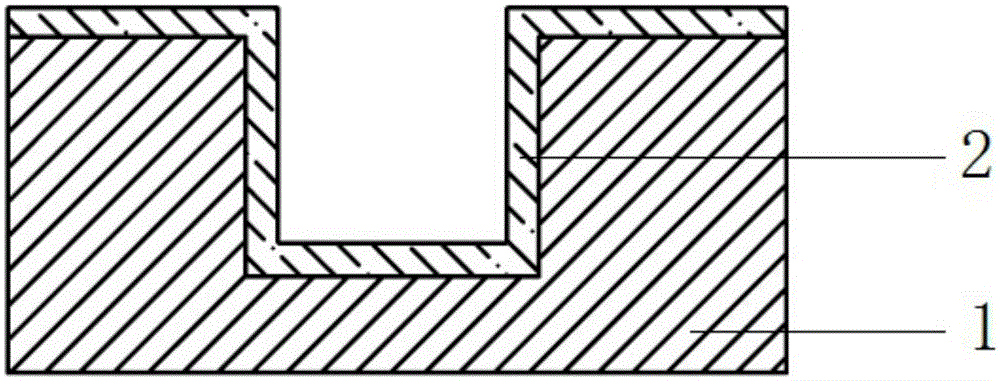

[0042] This embodiment provides a trench capacitor and its preparation method, such as Figure 8 As shown, the trench capacitor includes a capacitor first plate 32 and a second plate 33 vertically formed in the substrate 1 and isolated from each other, and an interposer sandwiched between the two capacitor plates 32 and 33. Electrical layer 4.

[0043] In this embodiment, the capacitor plates 32 and 33 are polysilicon plates doped with impurity P, and the resistance value is less than 15Ω / □, which endows the trench capacitor with a larger capacitance value.

[0044] The substrate 1 is a silicon substrate. As a convertible embodiment of the present invention, the substrate 1 is selected from but not limited to an N-type silicon substrate and a P-type silicon substrate, both of which can achieve the purpose of the present invention and belong to protection scope of the present invention.

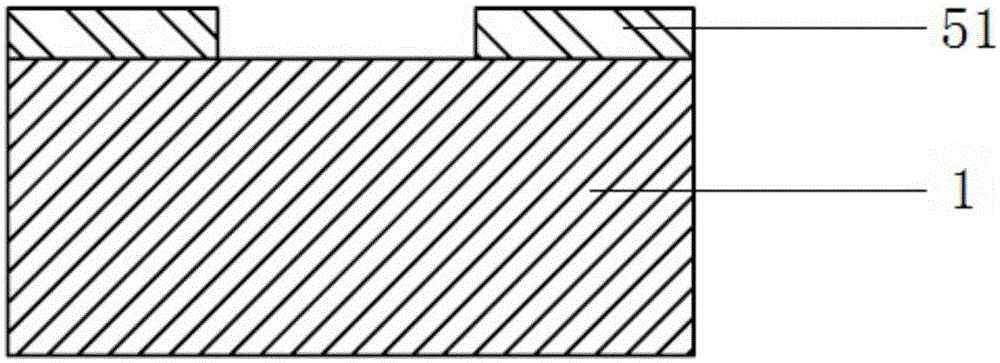

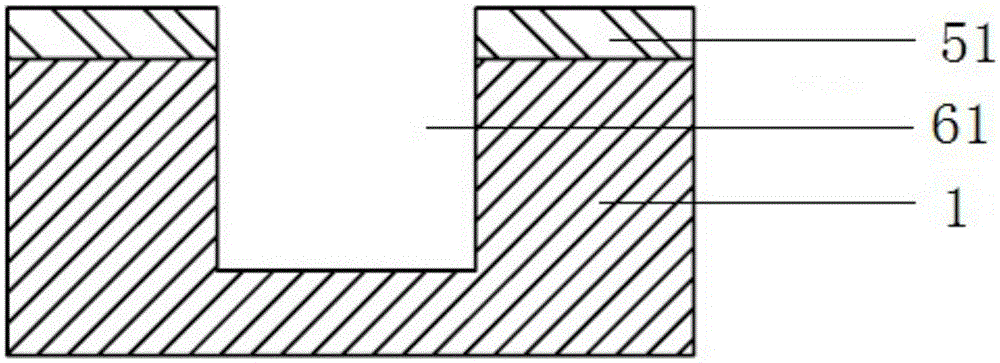

[0045] The preparation method of the trench capacitance, such as Figure 13 shown, incl...

Embodiment 2

[0062] This embodiment provides a trench capacitor and its preparation method, such as Figure 12 As shown, the trench capacitor includes a capacitor first plate 32 and a second plate 33 vertically formed in the substrate 1 and isolated from each other, and an interposer sandwiched between the two capacitor plates 32 and 33. Electrical layer 4.

[0063] In this embodiment, the capacitor plates 32 and 33 are polysilicon plates doped with impurity P, and the resistance value is less than 15Ω / □, which endows the trench capacitor with a larger capacitance value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com