Pneumatic radial tire for use on passenger vehicle

A technology for radial tires and passenger cars, which is applied to the reinforcement layer of pneumatic tires, road car tires, special tires, etc., can solve the problems of increased tire weight, increased vehicle resistance, and excess tire load capacity, and achieves improved wetness. Effects of Pavement Performance and Rolling Resistance Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

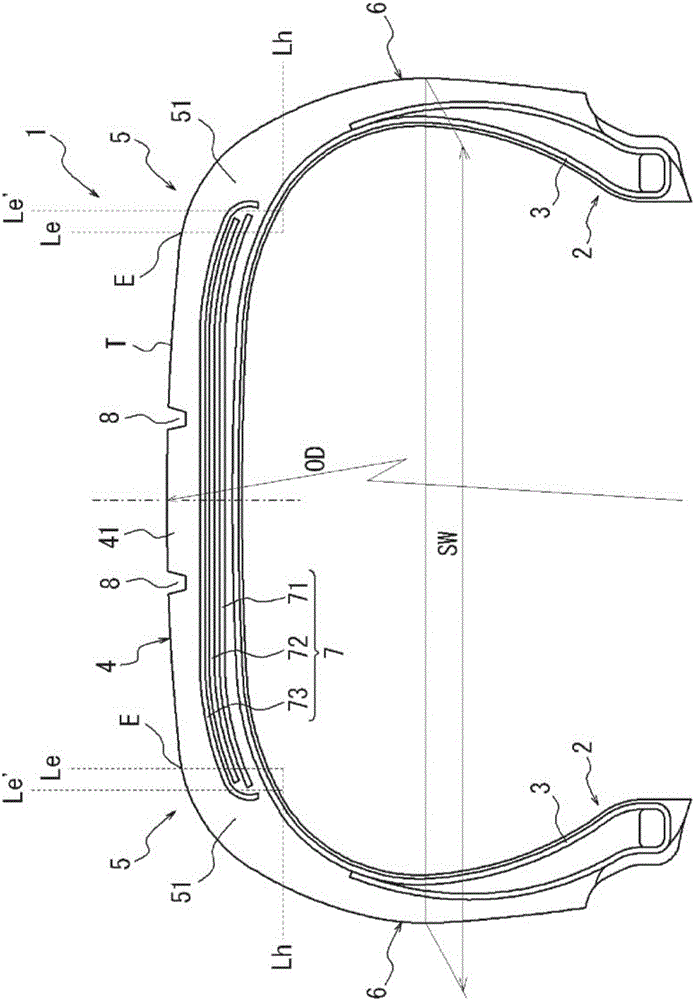

[0165] The tire of Example 1 is figure 1 The tire shown is a tire of size 165 / 60R19 and has the construction shown in Table 1. Furthermore, the tire of Example 1 was provided with two slanted belt layers in which belt cords obliquely cross each other in opposite directions with respect to the tire circumferential direction and a belt reinforcing layer. Three circumferential main grooves (circumferential main grooves with a groove width of 7.5 mm) were arranged on the face surface. In the tire of Example 1, the width of the tread surface in the tire width direction was 125 mm.

[0166] The tires of Example 2 to Example 4 were the same as the tire of Example 1 except that the structure was changed as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com