Heat-storage, thermally conductive sheet

A heat-conducting sheet and heat storage technology, applied in semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve problems such as easy damage, achieve uniform heat dissipation, reduce heating or hot spots, and reduce thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] 1. Material composition

[0101] (1) Silicone ingredients

[0102] A two-component room temperature curing silicone rubber was used as the silicone component. In addition, a base polymer component (component A), a crosslinking component (component B), and a platinum-based metal catalyst (component C) are added in advance to the two-liquid RTV.

[0103] (2) Thermal storage inorganic particles

[0104] Vanadium dioxide particles (VO 2 ), and mix evenly to form a compound. Vanadium dioxide particles (VO 2 ) The latent heat generated by the electronic phase transition is 245J / cc.

[0105] 2. Sheet forming processing method

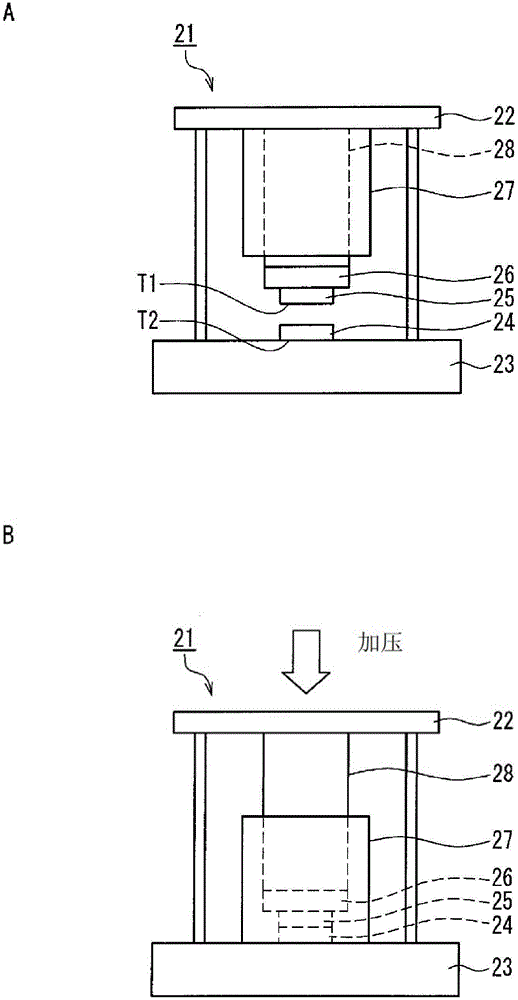

[0106] A metal frame with a thickness of 3 mm was placed on the polyester film subjected to mold release treatment, the composite was poured in, and another polyester film subjected to mold release treatment was placed. This was cured at 120° C. for 10 minutes under a pressure of 5 MPa to form a heat storage silicone rubber sheet with a thickness...

Embodiment 2

[0112] 1. Material composition

[0113] (1) Silicone ingredients

[0114] A two-component room temperature curing silicone rubber was used as the silicone component. In addition, a base polymer component (component A), a crosslinking component (component B), and a platinum-based metal catalyst (component C) are added in advance to the two-liquid RTV.

[0115] (2) Thermal storage inorganic particles

[0116] Vanadium dioxide particles (VO 2 ) and mix evenly.

[0117] 2. Sheet forming processing method

[0118] A sheet was molded in the same manner as in Example 1. Table 1 summarizes the physical properties of the obtained heat storage silicone rubber sheet.

[0119] [Table 1]

[0120] Example 1 Example 2 Silicone ingredients (parts by mass) 100 100 Addition amount of heat storage material particles (parts by mass) VO 2 : 600

VO 2 : 400

Heat storage (time to reach 42-85°C: seconds) 60 55 Thermal conductivity in thickness d...

Embodiment 3

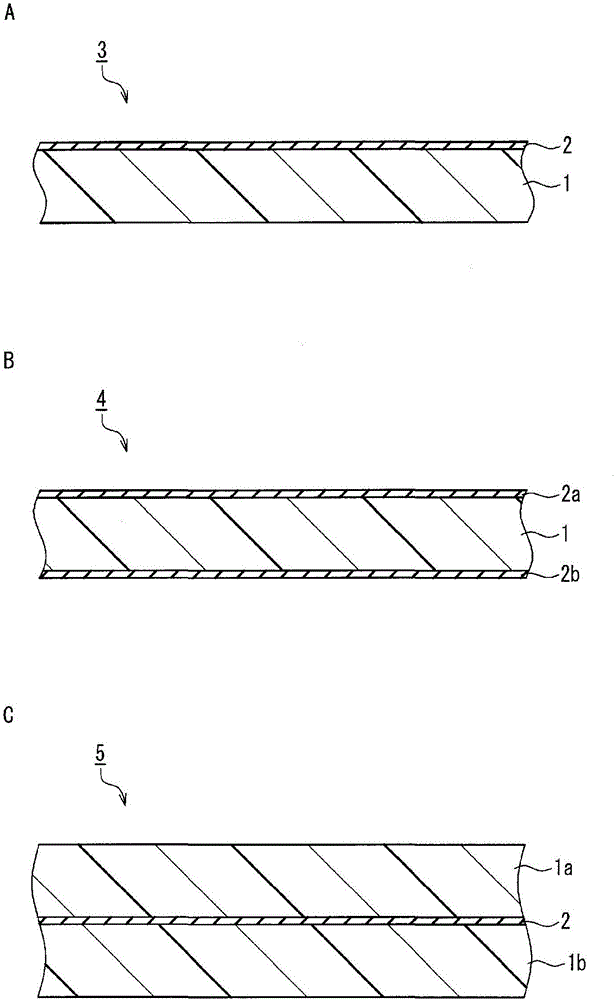

[0126] This embodiment is an experimental example of a heat storage material, a composite product of a silicone rubber sheet (thickness 1.0mm) and a graphite sheet (thickness 0.1mm) added with heat dissipation fillers.

[0127] 1. Material composition

[0128] (1) Silicone ingredients

[0129] A two-component room temperature curing silicone rubber was used as the silicone component. In addition, a base polymer component (component A), a crosslinking component (component B), and a platinum-based metal catalyst (component C) are added in advance to the two-liquid RTV.

[0130] (2) Thermal storage inorganic particles

[0131] Vanadium dioxide particles (VO 2 ) and mix evenly.

[0132] (3) Thermally conductive filler

[0133] Alumina particles (Al 2 o 3 ) and mix evenly.

[0134] 2. Sheet forming processing method

[0135] A sheet was molded in the same manner as in Example 1. Table 2 summarizes the physical properties of the obtained heat storage silicone rubber sheet....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com