Preparation method of Fe3O4@SiO2@ZnO magnetic nano photocatalyst

A photocatalyst and magnetic nanotechnology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of toxic dispersants or raw materials, poor solid-liquid separation effect, magnetic ZnO retention, etc. Achieve the effects of wide application range, excellent microwave heat transfer performance, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Chapter 1 Preparation Method

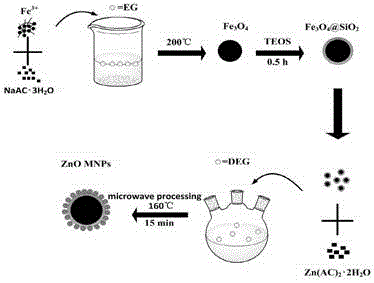

[0054] a kind of Fe 3 o 4 @SiO 2 The preparation method of @ZnO magnetic nano photocatalyst comprises the following steps:

[0055] (1) Weigh 2.24g Zn(CH 3 COO) 2 2H 2 O was added to a portion of 100mL DEG solution, and ultrasonically assisted to dissolve for 10min, and then heated for 5min at a microwave power of 600W and a temperature of 150°C to obtain the first intermediate reaction solution;

[0056] (2) Weigh 0.2g Fe 3 o 4 @SiO 2 Add it into another 20mL DEG solution, and carry out ultrasonic-assisted dissolution for 10min, and then heat for 5min under the conditions of microwave power of 600W and temperature of 150°C to obtain the second intermediate reaction solution;

[0057] (3) mixing the first intermediate reaction liquid and the second intermediate reaction liquid, and then heating for 15 min under the conditions of microwave power of 600W and temperature of 160°C to obtain a mixed reaction liquid;

[0058] (4) After...

Embodiment 2

[0203] a kind of Fe 3 o 4 @SiO 2 The preparation method of @ZnO magnetic nano photocatalyst comprises the following steps:

[0204] (1) Zn(CH 3 COO) 2 2H 2 O: DEG = 2.0g: 90mL mixed, and ultrasonically assisted to disperse for min, then heated for 5min under the condition of microwave power of 550W and temperature of 145°C to obtain the first intermediate reaction solution; (2) according to the weight volume ratio of Fe 3 o 4 @SiO 2 : DEG=0.15g: 15mL mixed, and ultrasonically assisted dispersion for 10min, then heated for 5min under the conditions of 550W and 145°C in microwave power to obtain the second intermediate reaction solution; (3) in parts by volume, 90 1 part of the first intermediate reaction solution and 15 parts of the second intermediate reaction solution were mixed, and then heated for 15 minutes at a microwave power of 550W and a temperature of 155°C to obtain a mixed reaction solution; (4) the mixed reaction solution was cooled to room temperature, cent...

Embodiment 3

[0210] a kind of Fe 3 o 4 @SiO 2 The preparation method of @ZnO magnetic nano photocatalyst comprises the following steps:

[0211] (1) Zn(CH 3 COO) 2 2H 2 O:DEG=2.5g:110mL mixed, and ultrasonically assisted to disperse for 12min, and then heated for 8min under the conditions of 650W and 155°C in microwave power to obtain the first intermediate reaction solution; (2) Fe 3 o 4 @SiO 2 : DEG=0.25g: 20mL were mixed, and ultrasonically assisted to disperse for 12min, and then heated for 8min under the conditions of 650W and 155°C in microwave power to obtain the second intermediate reaction solution; (3) according to volume fraction, 110 One part of the first intermediate reaction solution and 25 parts of the second intermediate reaction solution were mixed, and then heated for 20 minutes under the condition of microwave power of 650W and temperature of 165°C to obtain the mixed reaction solution; (4) the mixed reaction solution was cooled to room temperature, centrifuged S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com