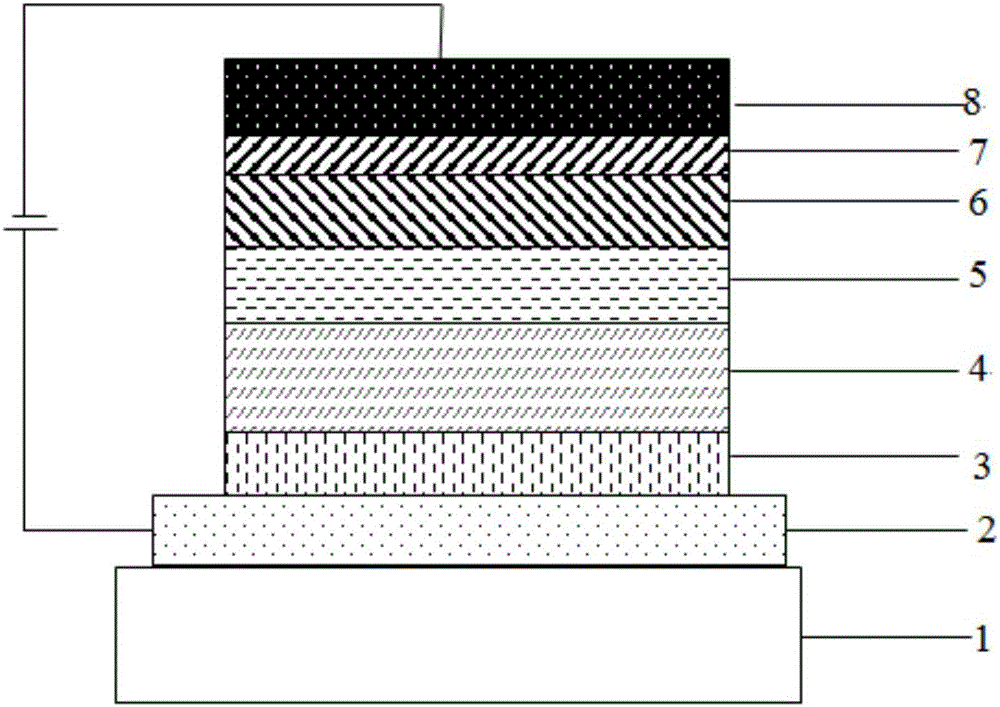

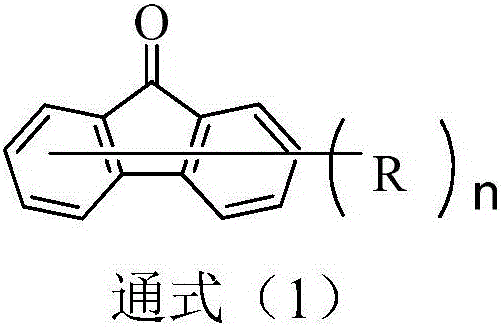

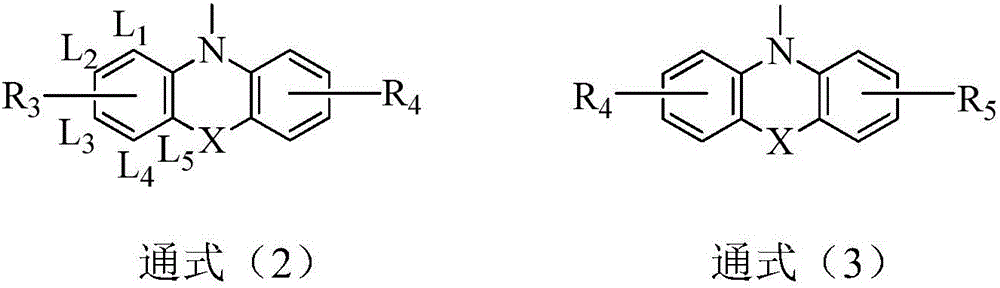

Organic electroluminescent material with 9-fluorenone as core and application thereof

A luminescent and electromechanical technology, applied in luminescent materials, organic chemistry, circuits, etc., can solve problems such as efficiency roll-off, low S1 state radiation transition rate, difficult exciton utilization rate and high fluorescence radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: the synthesis of compound 11:

[0077] synthetic route:

[0078]

[0079] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-9-fluorenone, 0.015mol intermediate A1, 0.03mol sodium tert-butoxide, 1×10 -4 molPd(dppf)Cl 2 , 180mL toluene, heated to reflux for 10 hours, sampled and spotted, the raw materials were completely reacted; naturally cooled to room temperature (20-25°C), filtered, and the filtrate was collected for vacuum rotary evaporation (-0.09MPa, 85°C), and column chromatography , to obtain the target product with a HPLC purity of 99.1% and a yield of 73.2%.

[0080] Elemental analysis structure (molecular formula C 46 h 30 N 2 o 2 ): theoretical value C, 85.96; H, 4.70; N, 4.36; 0, 4.98; test value: C, 85.95;

[0081] HPLC-MS: The theoretical molecular weight of the material is 642.74, and the measured molecular weight is 642.97.

Embodiment 2

[0082] Embodiment 2: the synthesis of compound 17:

[0083] synthetic route:

[0084]

[0085] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-9-fluorenone, 0.015mol intermediate B1, 0.03mol sodium tert-butoxide, 1×10 -4 molPd(dppf)Cl 2 , 180mL toluene, heated to reflux for 10 hours, sampled and spotted, the raw materials were completely reacted; naturally cooled to room temperature (20-25°C), filtered, and the filtrate was collected for vacuum rotary evaporation (-0.09MPa, 85°C), and column chromatography , the target product was obtained, the HPLC purity was 99.3%, and the yield was 74.8%.

[0086] Elemental analysis structure (molecular formula C 46 h 30 N 2 o 2 ): theoretical value C, 85.96; H, 4.70; N, 4.36; O, 4.98; test value: C, 85.94; H, 4.72; N, 4.37;

[0087] HPLC-MS: The theoretical molecular weight of the material is 642.74, and the measured molecular weight is 642.95.

Embodiment 3

[0088] Embodiment 3: the synthesis of compound 38:

[0089] synthetic route:

[0090]

[0091] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-9-fluorenone, 0.015mol intermediate C1, 0.03mol sodium tert-butoxide, 1×10 -4 molPd(dppf)Cl 2 , 180mL toluene, heated to reflux for 10 hours, sampled and spotted, the raw materials were completely reacted; naturally cooled to room temperature (20-25°C), filtered, and the filtrate was collected for vacuum rotary evaporation (-0.09MPa, 85°C), and column chromatography , to obtain the target product with a HPLC purity of 99.5% and a yield of 74.2%.

[0092] Elemental analysis structure (molecular formula C 49 h 36 N 2 o 2 ): theoretical value C, 85.94; H, 5.30; N, 4.09; 0, 4.67; test value: C, 85.95;

[0093] HPLC-MS: The theoretical molecular weight of the material is 684.82, and the measured molecular weight is 685.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com