Visually positioning system for circuit breaker release screw

A visual positioning and circuit breaker technology, applied in the direction of circuit breaker testing, etc., can solve problems such as difficulty in meeting automatic, fast, and high-precision testing requirements, large time lag of laser positioning and tracking screws, and affecting laser positioning accuracy. Achieve the effect of test automation, test time shortening, fast and accurate positioning and tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

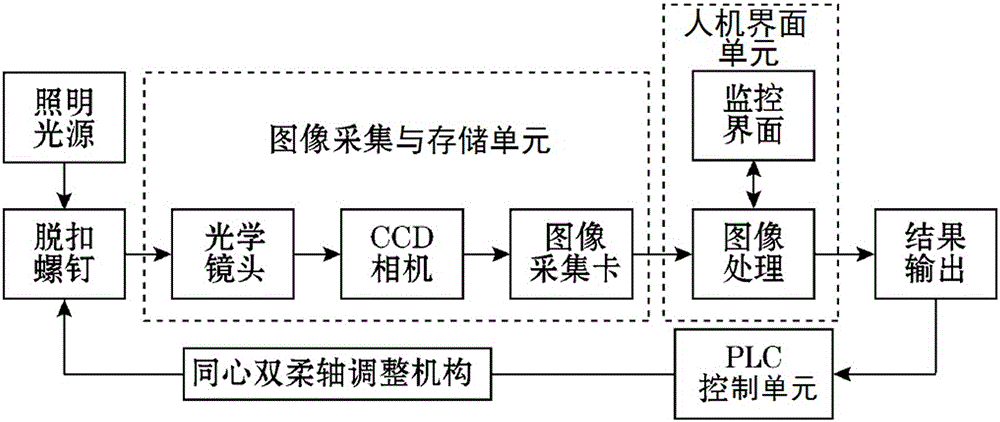

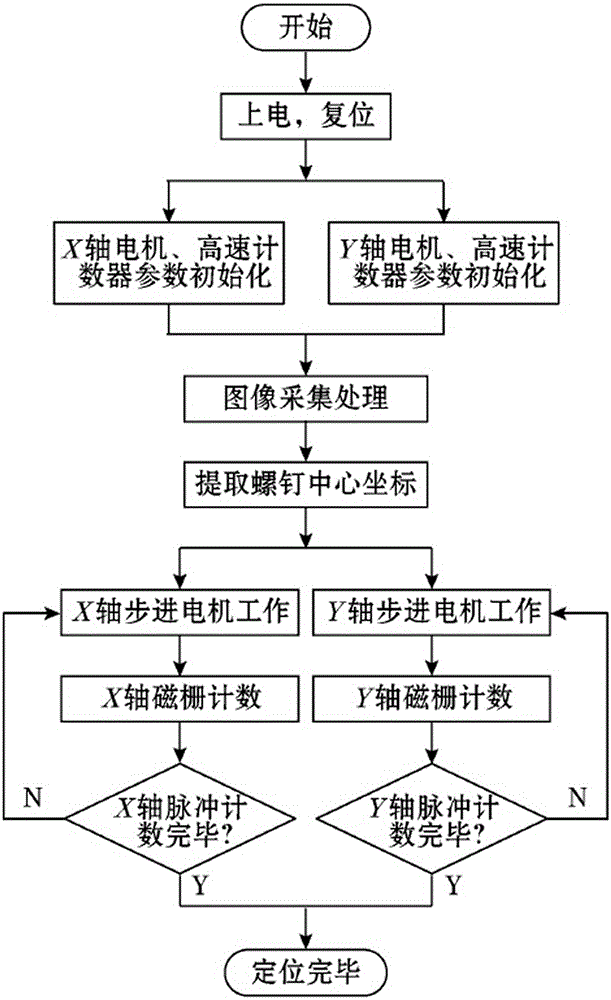

[0017] like figure 1 As shown, it is a composition block diagram of a circuit breaker tripping screw visual positioning system of the present invention. In the figure, it includes an illumination light source, an image acquisition storage unit, a man-machine interface unit, a PLC control unit and a screw adjustment control unit; its structural points are: the image acquisition storage unit includes an optical lens, a CCD camera, an image acquisition card, and the The optical lens is installed on the CCD camera, and the output end of the CCD camera is connected with the image acquisition card; the screw adjustment control unit is a concentric double-flexible axis adjustment mechanism, and the man-machine interface unit includes a monitoring interface and an image processing module. The monitoring interface and the image processing module are connected to each other; the output end of the image acquisition card is connected to the input end of the image processing module, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com