Adsorbent agent for treating compressed gas, method for producing same, and adsorption device provided with such adsorbent agent

一种压缩气体、制造方法的技术,应用在分离方法、气体处理、化学仪器和方法等方向,能够解决粘结功能下降、硅胶吸附功能下降、支持性玻璃纤维基体结构强度损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

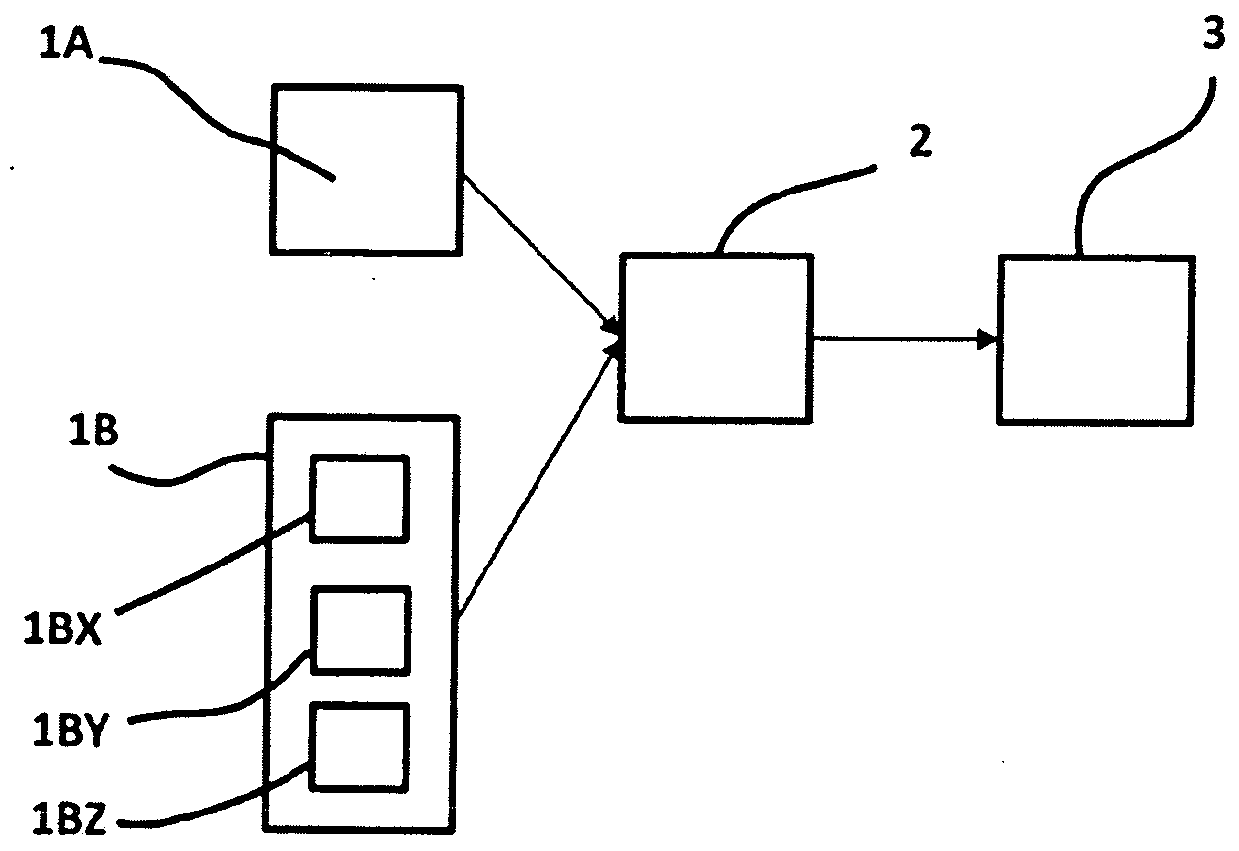

[0029] figure 1 A block diagram is shown, where each block lists a step of the method according to the invention, and where in some blocks a number of sub-steps are distinguished between them.

[0030] The method according to the invention for producing an adsorbent agent for treating compressed gases essentially consists of step 1A and step 1B, wherein step 1A provides a monolithic support structure and step 1B consists in producing a coating suspension containing the adsorbent.

[0031] In the next step 2, the aforementioned coating suspension is applied to the aforementioned support structure to form a coating, and finally in step 3, a heat treatment is applied to the resulting support structure with the coating obtained after step 2, thereby sintering The aforementioned coatings result in improved adsorbent reagents.

[0032] According to a preferred, but not essential, feature of the invention, a ceramic structure comprising cordierite is selected for the monolithic supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com