Axle steel and continuous casting method thereof

A continuous casting technology for axle steel, which is applied in the field of automotive steel, can solve problems such as insufficient reduction, incomplete welding of central shrinkage cavities, and limited improvement in billet density, so as to achieve improved product quality, good use effect, Effect of improving density and homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment is to use the continuous casting method of the present invention to improve the center density of the LZ50 axle steel billet, specifically:

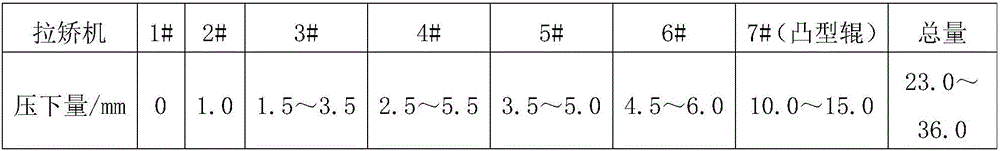

[0058] Continuous casting produces LZ50 blooms with a cross-sectional size of 360mm×450mm. The casting speed of the casting machine is 0.52m / min, and the casting speed is kept stable. The superheat of molten steel in the tundish is 25°C. control, the specific water volume of secondary cooling is 0.45kg / t 钢 ;The large reduction control at the end of solidification is adopted, the reduction rate is 1.5mm / min, the length of the reduction interval is 7.7m, the number of reduction rollers is 6, the total reduction is 31mm, and the reduction of 2# roller is 1.0mm. 3# roller reduction is 1.5mm, 4# roller reduction is 5.5mm, 5# roller reduction is 5.0mm, 6# roller reduction is 5.0mm, 7# roller reduction is 13.0mm.

[0059] After the pouring is completed, low-magnification inspection is carried out on the internal quality ...

Embodiment 2

[0061] This embodiment is to use continuous casting method of the present invention to improve U78CrV axle steel billet central density, specifically:

[0062] Continuous casting produces U78CrV blooms with a cross-sectional size of 360mm×450mm. The casting speed of the casting machine is 0.45m / min, and the casting speed is kept stable. The superheat of molten steel in the tundish is 20°C. control, the specific water volume of secondary cooling is 0.40kg / t 钢 ;Adopt the large reduction control at the end of solidification, the reduction rate is 1.0mm / min, the length of the reduction interval is 5.2m, the number of reduction rollers is 5, the total reduction is 27.5mm, and the reduction of 2# roller is 1.0mm , 3# roller reduction 2.5mm, 4# roller reduction 4.5mm, 5# roller reduction 3.5mm, 6# roller reduction 6.0mm, 7# roller reduction 10.0mm.

[0063] After the pouring is completed, low-magnification inspection is carried out on the internal quality of the bloom billet. The in...

Embodiment 3

[0065] This embodiment is to use the continuous casting method of the present invention to improve the center density of 45# axle steel billet, specifically:

[0066] Continuous casting produces 45# steel blooms with a cross-sectional size of 360mm×450mm. The casting speed of the casting machine is 0.65m / min, and the casting speed is kept stable. The superheat of the molten steel in the tundish is 30°C. Cooling dynamic control, the specific water volume of the secondary cooling is 0.50kg / t 钢 ;The large reduction control at the end of solidification is adopted, the reduction rate is 2.3mm / min, the length of the reduction interval is 4.5m, the number of reduction rollers is 4, the total reduction is 32mm, and the reduction of 2# roller is 1.0mm. 3# roller reduction is 3.5mm, 4# roller reduction is 3.5mm, 5# roller reduction is 4.5mm, 6# roller reduction is 4.5mm, 7# roller reduction is 15.0mm.

[0067] After the pouring is completed, low-magnification inspection is carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com