A partition construction bionic coupling surface repair waste machine tool guide rail and its method

A surface repair and guide rail technology, which is applied to the field of uniform repair of waste machine tool guide rails, can solve the problems of not considering interval hardness value, uneven wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

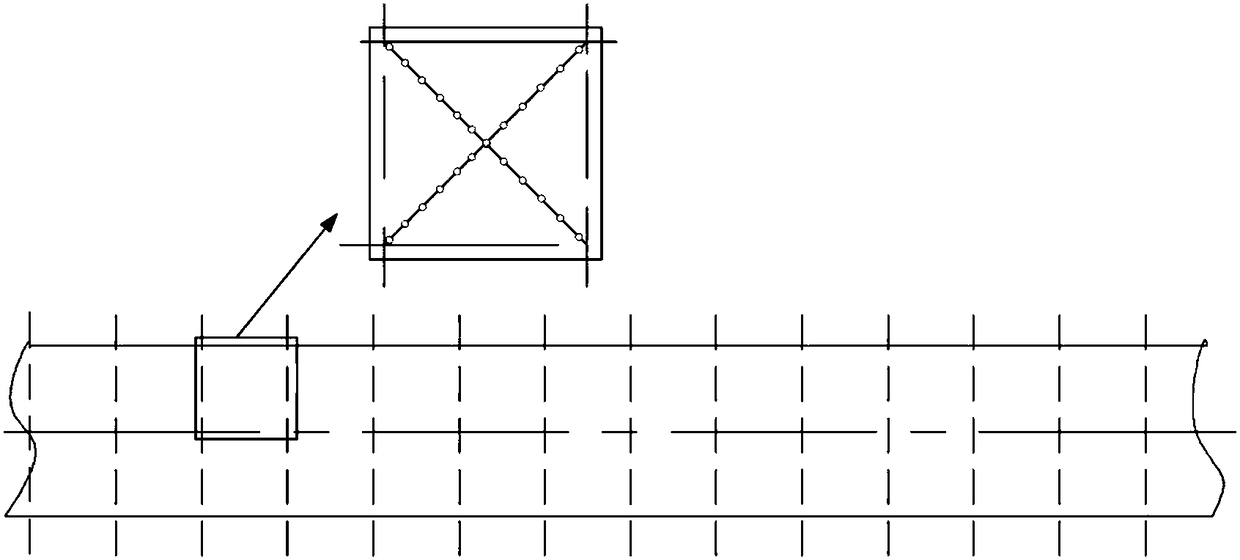

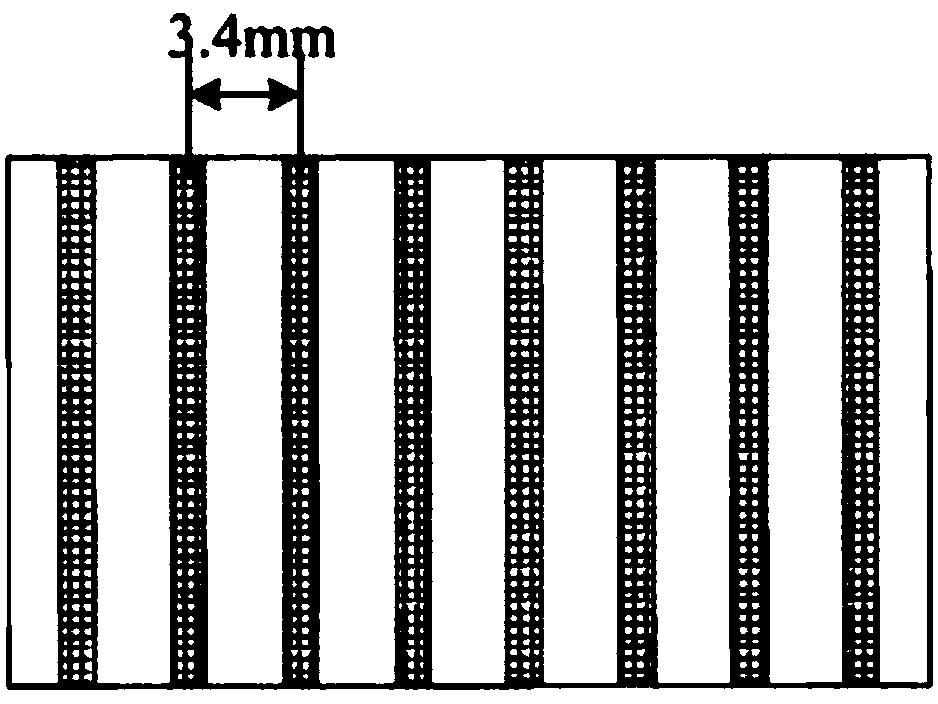

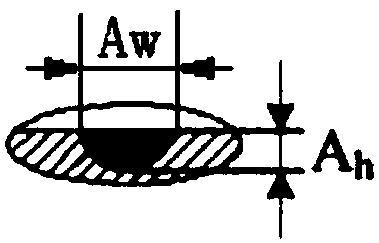

[0038] The biological prototype selected in the present invention is the head of the dung beetle, the plant leaf and the surface of the shell, which are generally inspired by biology, and then optimize and transform the combination according to the actual situation. The bionic non-smooth structure can be divided into point-shaped, Strip, mesh, dot-strip combination, dot-net combination. And through experiments, it is found that the bionic unit body processed by laser on the remaining quenched surface of the scrap machine tool has phase transfer, and the metallographic structure changes from pearlite to high-hardness martensite. The bionic coupling unit body can be used as a hard phase to provide strength and hardness. The guide rail material itself acts as a soft phase to provide toughness and shock absorption. The combination of the two soft and hard bionic coupling surfaces can improve the wear resistance of the machine tool guide.

[0039] In the present invention, due to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com